Tension test equipment with protection function

A tensile test and protection function technology, applied in the direction of using stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of accidental breakage of metal wires, injury to inspectors, and easy collapse of fixed ends. Achieve the effect of fast sliding speed, fast stretching speed and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

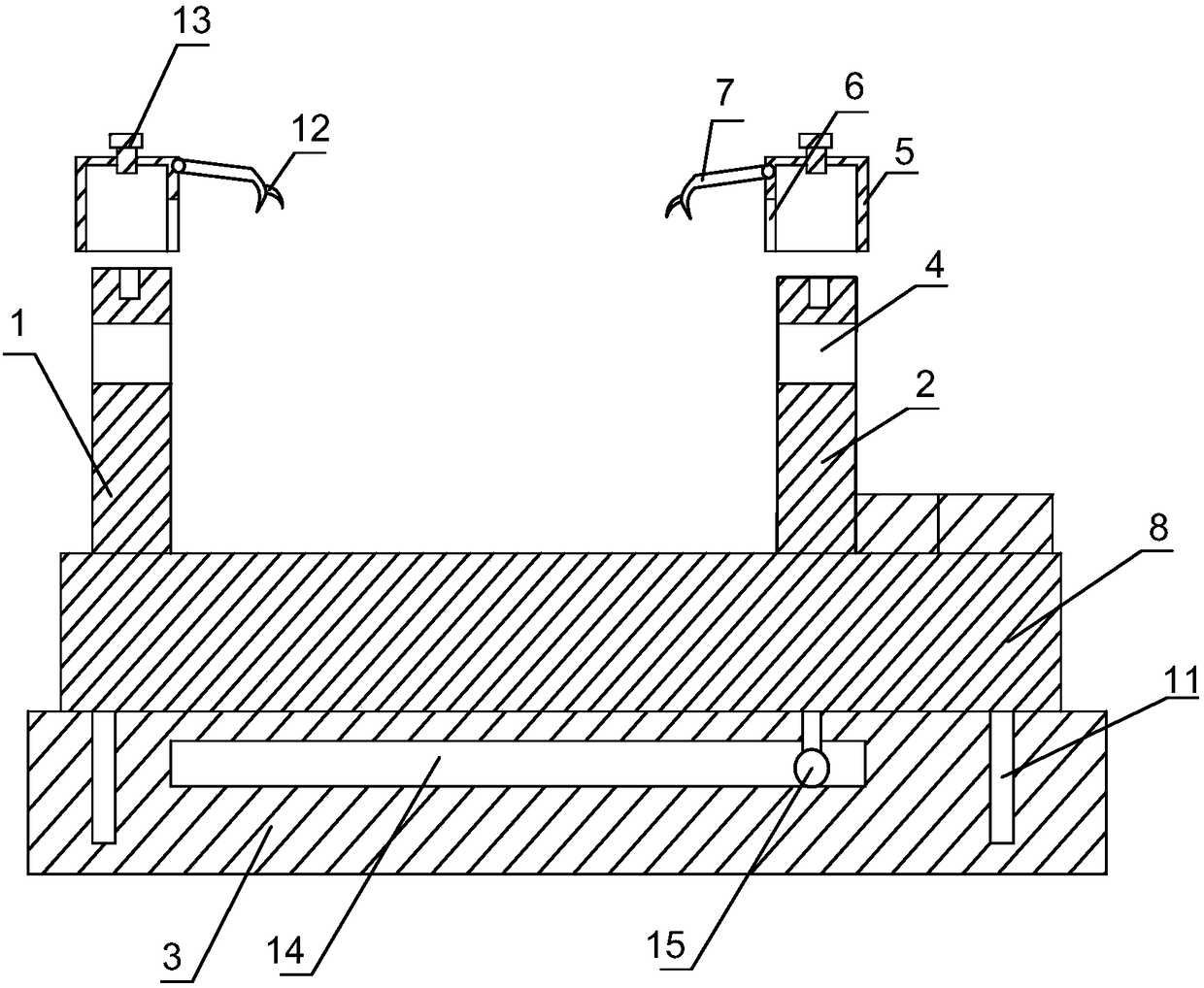

[0024] like figure 1 , figure 2 As shown, the tensile testing equipment with protective function of the present invention includes a testing machine body, and the testing machine body includes a first fixed seat 1 and a second fixed seat 2 placed in parallel, and the metal wire to be tested is connected to the first fixed seat 1, the second fixed seat 2 Between the second fixed seat 2, the first fixed seat 1 and the second fixed seat 2 are connected with a horizontally placed support seat 3, the first fixed seat 1 and the second fixed seat 2 are all vertical to the support seat 3, and the first fixed seat 2 is vertical to the support seat 3. The seat 1 is fixedly connected with the support seat 3, and the second fixed seat 2 is slidingly connected with the support seat 3. To the moving motive mechanism, the first fixed seat 1 and the second fixed seat 2 are provided with relative through holes 4, and the tops of the first fixed seat 1 and the second fixed seat 2 are equipped...

Embodiment 2

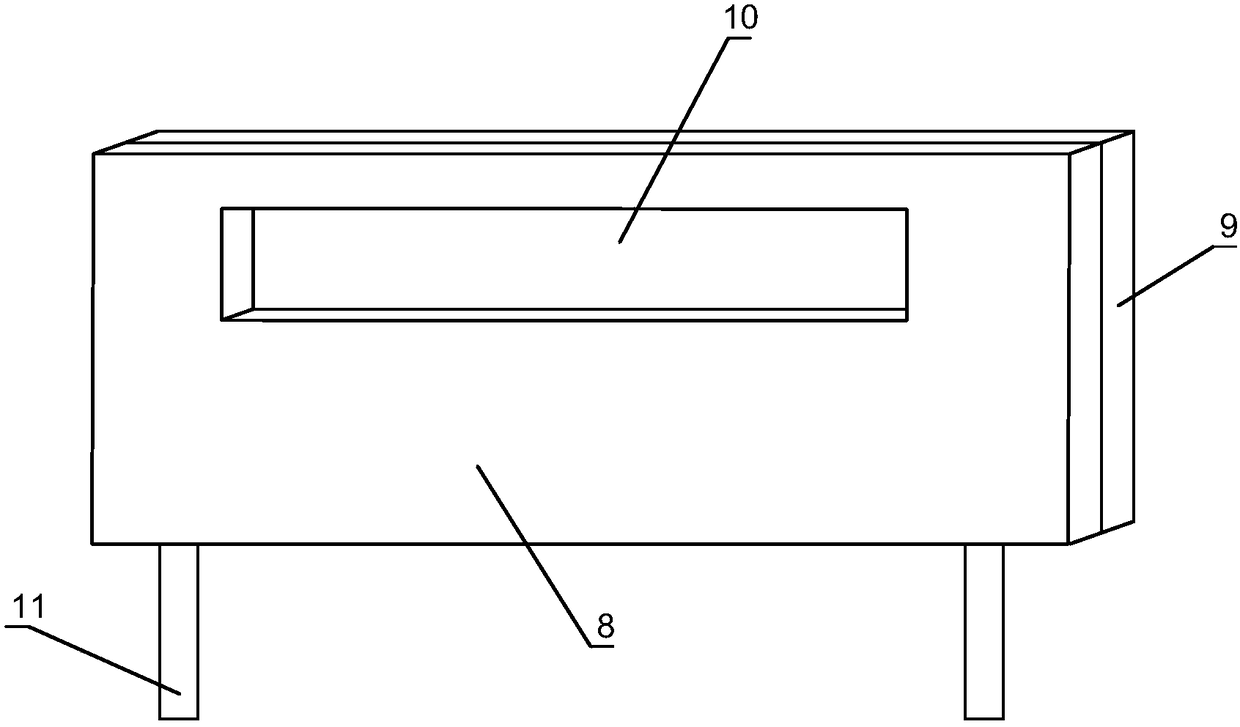

[0027] Based on Embodiment 1, a baffle 8 is connected to the support seat 3, and the baffle 8 is located on one side of the first fixed seat 1 and the second fixed seat 2, and the height of the baffle 8 is higher than that of the first fixed seat 1 and the second fixed seat. The height of the seat 2, the length of the baffle plate 8 is longer than the furthest distance between the first fixed seat 1 and the second fixed seat 2, the bottom of the baffle plate 8 is connected with many pins 11 inserted into the support seat 3, and the support seat 3 is provided with A jack that mates with pin 11. The side walls of the baffle plate 8 close to the first fixed seat 1 and the second fixed seat 2 are completely covered with a foam layer 9, the baffle plate 8 and the foam layer 9 are provided with interconnected through grooves, and transparent silica gel is installed inside the through grooves Pad 10.

[0028] The baffle plays a protective role for the inspectors. After installing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com