Heat accumulating type catalytic combustion device

A catalytic combustion and regenerative technology, applied in combustion methods, combustion types, incinerators, etc., can solve problems such as affecting the purification effect of organic waste gas, wasting catalyst combustion energy, and increasing practical costs, so as to increase catalytic efficiency and improve Efficiency, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

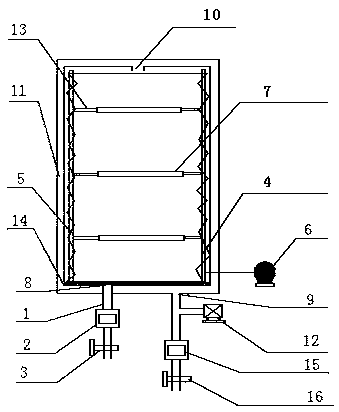

[0015] Such as figure 1 As shown, the regenerative catalytic combustion device includes an air intake device and a reaction device. The air intake device includes an air intake pipe 1, a gas flow controller A2 and a control valve A3. The air intake pipe 1 is sequentially provided with gas The flow controller 2 and the control valve A3, the reaction device includes a copper tube 4 arranged on the inner wall of the reaction device, an induction coil 5 arranged on the copper tube, a high-frequency induction heating device 6 connected to the induction coil 5 and a plurality of A metal perforated plate 7, the bottom of the reaction device is provided with an air inlet 8, and the top of the reaction device is provided with an air return port 10, and the return air port 10 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com