Onion grape wine and preparation method thereof

A wine and grape original wine technology, applied in the field of onion wine and its preparation, can solve the problems of not meeting the quality needs of high-end consumers, uneven wine quality, high content of bacteria and impurities, etc., to eliminate free radicals, shorten process time, The effect of protecting blood vessels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

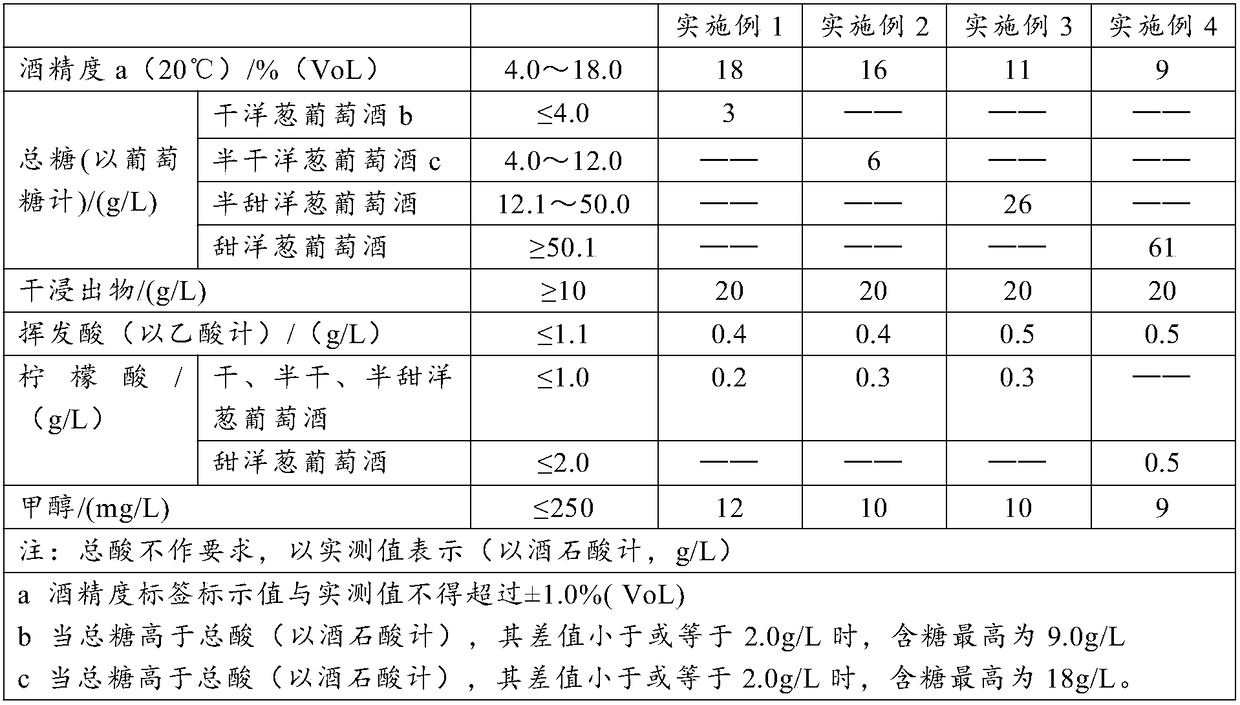

Examples

Embodiment 1

[0041] The preparation of embodiment 1 dry onion wine

[0042] (1) Grape sorting: select red grapes that are fresh, free of mildew, free of impurities, free of disease, free of phytotoxicity, and free of pollution. The sugar content of the red grape juice is ≥140g / L.

[0043] (2) Destemming and crushing: Put the red grapes into the destemming crusher through the conveyor. Pulp (juice) cannot be in direct contact with metals such as iron and copper.

[0044] (3) Fruit pulp into the tank: the crushed pulp is input into the fermentation tank through the pulp pump, and the input amount of the pulp is 75% of the tank capacity; slowly and evenly add potassium metabisulfite with a concentration of 56% according to 60mg / L , add pectinase at 25mg / L. The usage of pectinase is: put the required amount of pectinase into 10 times pure water, stir and dissolve, add it to the tank, and mix it with pump circulation;

[0045] (4) Alcoholic fermentation:

Embodiment 2

[0063] The preparation of embodiment 2 semi-dry onion wine

[0064] (1) Grape sorting: select red grapes that are fresh, free of mildew, free of inclusions, disease-free, phytotoxicity, and pollution-free, and the sugar content of the red grape juice is ≥160g / L.

[0065] (2) Destemming and crushing: Put the red grapes into the destemming crusher through the conveyor. Pulp (juice) cannot be in direct contact with metals such as iron and copper.

[0066] (3) Fruit pulp into the tank: the crushed pulp is input into the fermentation tank through the pulp pump, and the pulp input is 75% of the tank capacity; slowly and evenly add potassium metabisulfite with a concentration of 56% at 50 mg / L , add pectinase at 20mg / L. The usage of pectinase is: put the required amount of pectinase into 10 times pure water, stir and dissolve, add it to the tank, and mix it with pump circulation;

[0067] (4) Primary fermentation:

[0068] Add yeast: add yeast 6 hours after adding pectinase, the a...

Embodiment 3

[0085] The preparation of embodiment 3 semi-sweet onion wine

[0086] (1) Grape sorting: select white grapes that are fresh, free of mildew, free of impurities, free of disease, free of phytotoxicity, and free of pollution. The sugar content of the white grape juice is ≥170g / L.

[0087] (2) Destemming and crushing: Put the white grapes into the destemming crusher through the conveyor. Pulp (juice) cannot be in direct contact with metals such as iron and copper.

[0088] (3) Fruit pulp into the tank: the crushed pulp is input into the fermentation tank through the pulp pump, and the pulp input is 75% of the tank capacity; slowly and evenly add potassium metabisulfite with a concentration of 56% according to 65mg / L , add pectinase at 30mg / L. The usage of pectinase is: put the required amount of pectinase into 10 times pure water, stir well and dissolve, add it to the tank, and mix it with pump circulation;

[0089] (4) Primary fermentation:

[0090] Add yeast: add yeast 6 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com