High-molecular adhesive and preparation method thereof

A manufacturing method and adhesive technology, which are applied in the directions of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of insufficient viscosity of the adhesive and achieve the effect of enhancing the use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

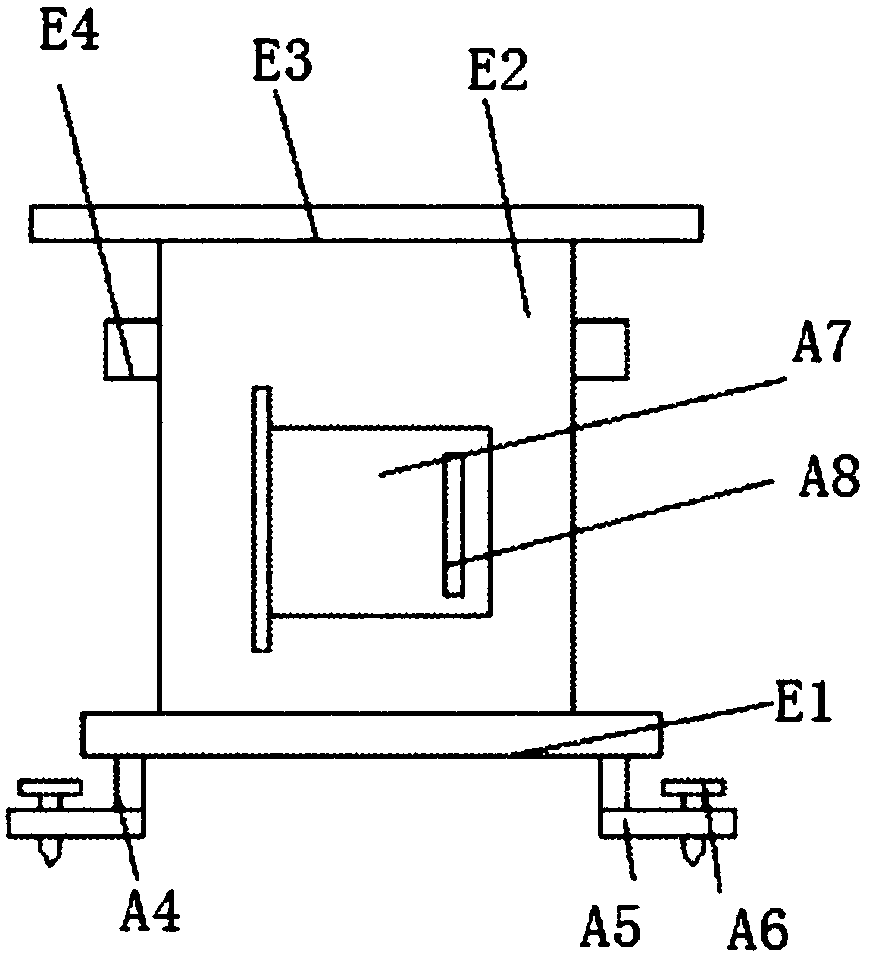

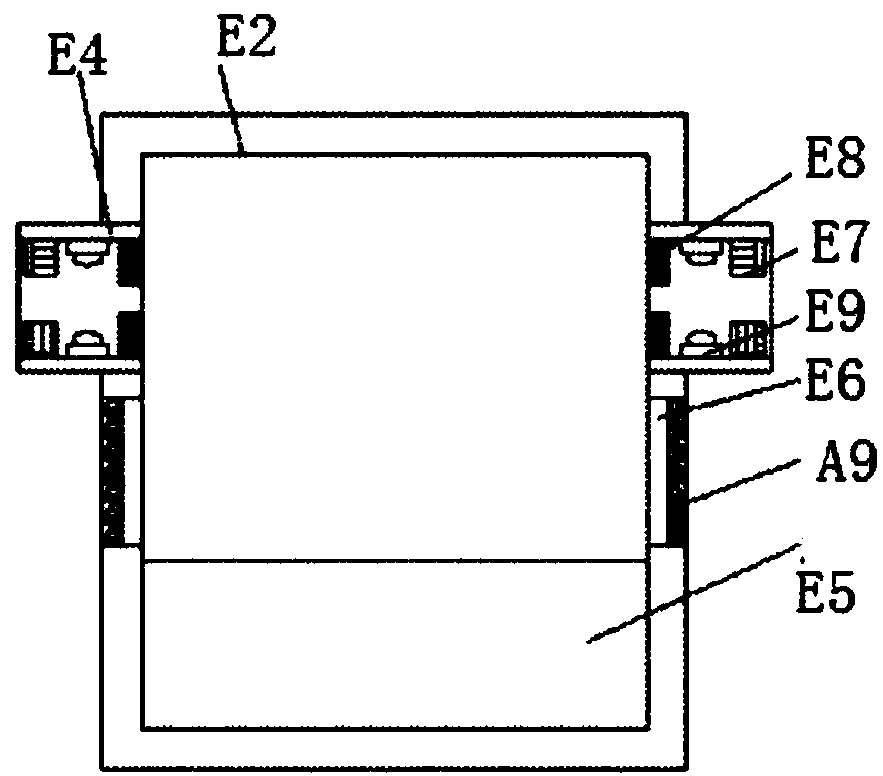

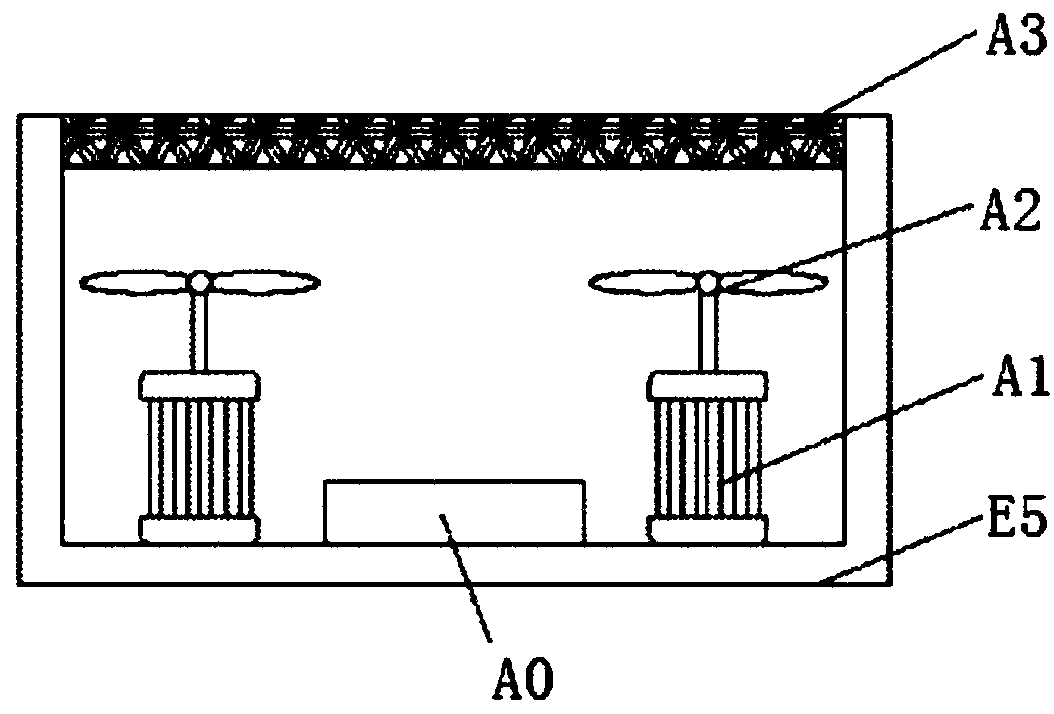

[0027] like Figure 1-Figure 3 As shown, the polymer adhesive, calculated according to parts by weight, its raw materials include: parts by weight of starch, 12 parts by weight of lipoic acid, 8 parts by weight of ethylphosphorus aluminum, parts by weight of 34 parts by weight of water glass, 24 parts by weight of dioctyl phthalate, 14 parts by weight of AEP, 36 parts by weight of normal hexane, 22 parts by weight of calcium stearoyl lactylate, The castor oil that is 38 parts by weight, the alpha-sulfomonocarboxylate that is 6 parts by weight, the sodium alginate that is 4 parts by weight, the chitin that is 24 parts by weight, the butyric acid that is 6 parts by weight Isopentyl acid, the vanillin of 4 parts by weight.

[0028] The manufacture method of described polymer adhesive is specifically as follows:

[0029] (1) Weigh the raw materials according to their respective parts by weight, raise the temperature of chitin to 90 degrees, then add n-hexane, starch, isoamyl but...

Embodiment 2

[0051] Such as Figure 1-Figure 3 As shown, the polymer adhesive, calculated according to parts by weight, its raw materials include: parts by weight of starch, 14 parts by weight of lipoic acid, 11 parts by weight of ethylphosphorus aluminum, parts by weight of 41 water glass, 27 parts by weight of dioctyl phthalate, 16 parts by weight of AEP, 38 parts by weight of normal hexane, 23 parts by weight of calcium stearoyl lactylate, weight Castor oil with 40 parts by weight, α-sulfomonocarboxylate with 9 parts by weight, sodium alginate with 5 parts by weight, chitin with 26 parts by weight, butyric acid with 12 parts by weight Isopentyl ester, the vanillin that parts by weight are 4.8.

[0052] The manufacture method of described polymer adhesive is specifically as follows:

[0053] (1) Weigh the raw materials according to their stated parts by weight, raise the temperature of chitin to 120 degrees, then add n-hexane, starch, isoamyl butyrate, vanillin and mix well, cool down ...

Embodiment 3

[0075] like Figure 1-Figure 3 As shown, the polymer adhesive, calculated according to parts by weight, its raw materials include: parts by weight of starch, 16 parts by weight of lipoic acid, 14 parts by weight of ethylphosphorus aluminum, parts by weight of 48 parts by weight of water glass, dioctyl phthalate of 30 parts by weight, AEP of 18 parts by weight, normal hexane of 40 parts by weight, calcium stearoyl lactylate of 24 parts by weight, weight Castor oil with 42 parts by weight, α-sulfomonocarboxylate with 12 parts by weight, sodium alginate with 6 parts by weight, chitin with 28 parts by weight, butyric acid with 18 parts by weight Isopentyl ester, the vanillin that parts by weight are 5.6.

[0076] The manufacture method of described polymer adhesive is specifically as follows:

[0077] (1) Weigh the raw materials according to their respective parts by weight, raise the temperature of chitin to 150 degrees, then add n-hexane, starch, isoamyl butyrate, vanillin and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com