Polycaprolactone-base diethylsulfopropyl betaine, preparation method thereof, and construction method with same as medicine release carrier

A technology of polycaprolactone-based diethylsulfopropyl beet and caprolactone-based diethylsulfopropyl beet, which is applied in the field of biomedical polymer materials, can solve problems such as poor long-term circulation ability, and achieve simple operation , good anti-protein adsorption performance, prolonging the effect of cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

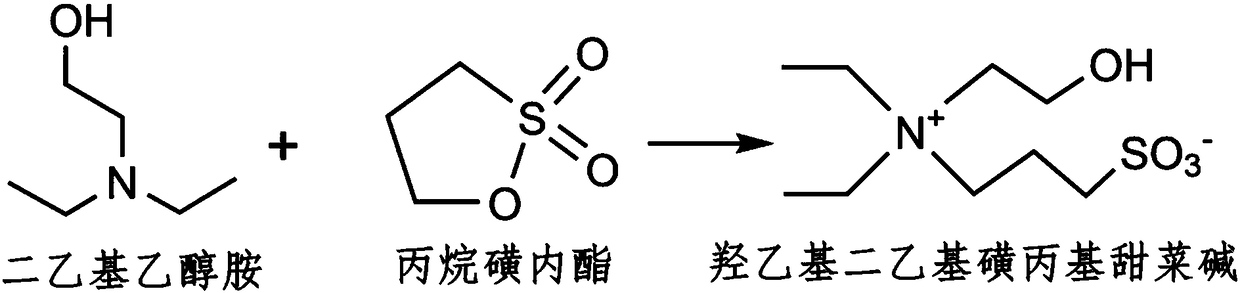

[0030] Embodiment 1: polycaprolactone base diethylsulfopropyl betaine preparation (I)

[0031] (1) Take by weighing 1.17g diethylethanolamine and be dissolved in 50ml toluene, magnetic stirring is mixed with the diethylethanolamine solution that mass concentration is 2.6%;

[0032] (2) Weighing 1.2g propane sultone was added and dissolved in 50ml toluene, and magnetically stirred to form a propane sultone solution with a mass concentration of 2.7%;

[0033] (3) Add the propane sultone solution obtained in step (2) dropwise to the diethylethanolamine solution obtained in step (1) at 50° C. and nitrogen gas, at a rate of 3 ml / min. After continuing to react for 12h, stop the reaction, filter the product and recrystallize in isopropanol to obtain hydroxyethyldiethylsulfopropyl betaine (SB), the reaction process is as follows figure 1 shown;

[0034] (4) 1.34g caprolactone and 0.22g SB are dissolved in 50ml toluene solution, wherein the mass concentration of caprolactone is 3%, t...

Embodiment 2

[0036] Embodiment 2: preparation of polycaprolactone-based diethylsulfopropyl betaine (II)

[0037] (1) Take by weighing 11.7g diethylethanolamine and be dissolved in 50ml toluene, magnetic stirring is mixed with the diethylethanolamine solution that mass concentration is 21.27%;

[0038] (2) Weighing 12.2g propane sultone was added and dissolved in 50ml toluene, and magnetically stirred to form a propane sultone solution with a mass concentration of 22%;

[0039] (3) Add the propane sultone solution obtained in step (2) dropwise to the diethylethanolamine solution obtained in step (1) at 60° C. and nitrogen gas, at a rate of 6 ml / min. After continuing to react for 24 hours, stop the reaction, filter the product and recrystallize in isopropanol to obtain hydroxyethyldiethylsulfopropyl betaine (SB);

[0040](4) 50.81g caprolactone and 2.27g SB are dissolved in 50ml toluene solution, wherein the mass concentration of caprolactone is 53%, and the concentration of SB is 2.5%; Aft...

Embodiment 3

[0042] Embodiment 3: preparation of polycaprolactone-based diethylsulfopropyl betaine (III)

[0043] (1) Take by weighing 23.4g diethylethanolamine and be dissolved in 50ml toluene, magnetic stirring is mixed with the diethylethanolamine solution that mass concentration is 35%;

[0044] (2) Weighing 24.4g propane sultone was added and dissolved in 50ml toluene, and magnetically stirred to form a propane sultone solution with a mass concentration of 35%;

[0045] (3) Add the propane sultone solution obtained in step (2) dropwise to the diethylethanolamine solution obtained in step (1) at 60° C. and nitrogen gas, at a rate of 8 ml / min. After continuing to react for 36 hours, stop the reaction, filter the product and recrystallize in isopropanol to obtain hydroxyethyldiethylsulfopropyl betaine (SB);

[0046] (4) 130.5g caprolactone and 0.48g SB are dissolved in 50ml toluene solution, wherein mass concentration of caprolactone is 75%, the concentration of SB is 0.2%; After mixing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com