Metalized film rolling device

A technology of metallized film and winding device, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of not effectively guaranteeing film winding, film folds, film breakage or breaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

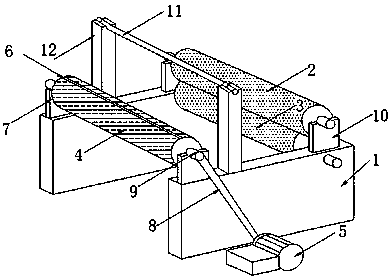

[0015] Example: such as figure 1 As shown, a metallized film winding device includes a fixed frame 1, and one end of the fixed frame 1 is provided with a pressure wheel support frame 10, and a pressure wheel A2 is arranged between the top of the pressure wheel support frame 10, and the pressure wheel support frame 10 The bottom is provided with a pinch wheel B3, the other end of the fixed frame 1 is provided with a rewinding wheel support frame 7, the rewinding wheel support frame 7 is provided with a rewinding wheel 4, and the rewinding wheel 4 two ends are provided with a pulley 9, and the pulley 9 is connected with motor 5 by belt 8, is provided with clip 6 on the rewinding wheel 4, is provided with tension rod holder 12 on the middle end of holder 1, and is provided with tension rod 11 on the tension rod holder 12.

[0016] The tension rod 11 is located between the pressure roller A2 and the winding wheel 4, the vertical height of the tension rod 11 is higher than that of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com