Mobile full-automatic steel pipe picking, cleaning, classification and packing device

A technology of picking up device and cleaning device, applied in packaging, grading, solid separation and other directions, can solve the problems of complex operation process, inconvenient movement, poor flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

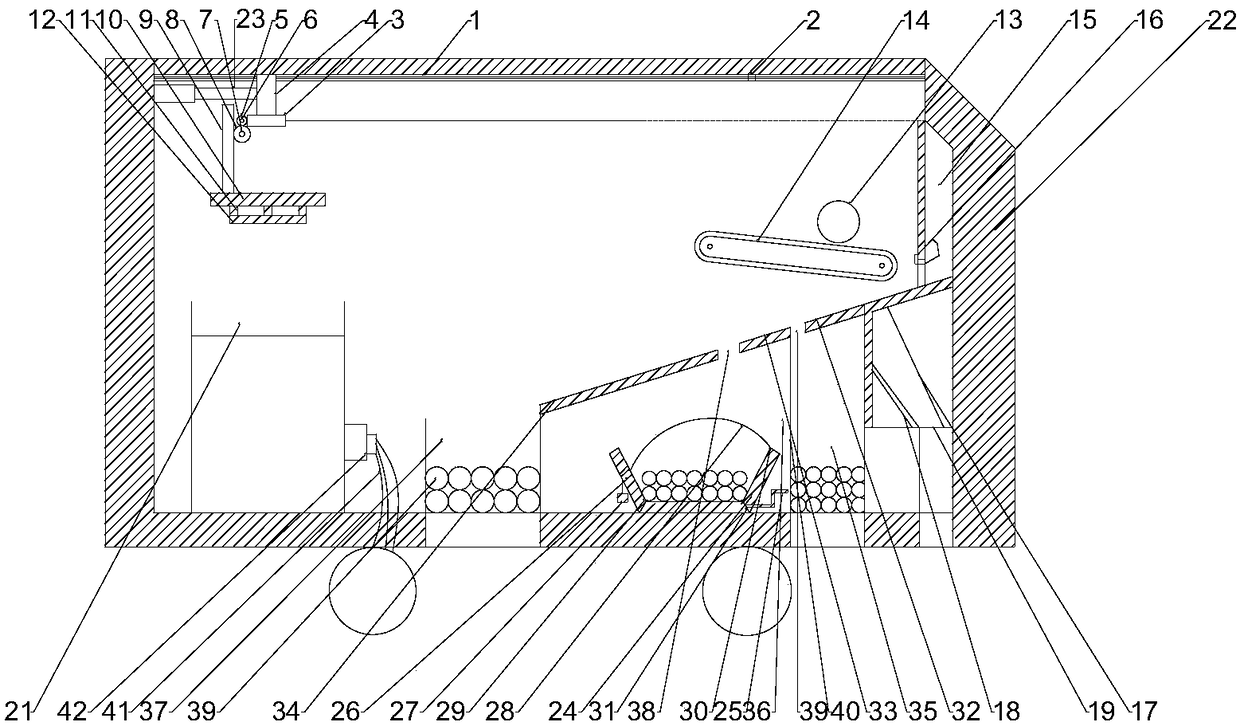

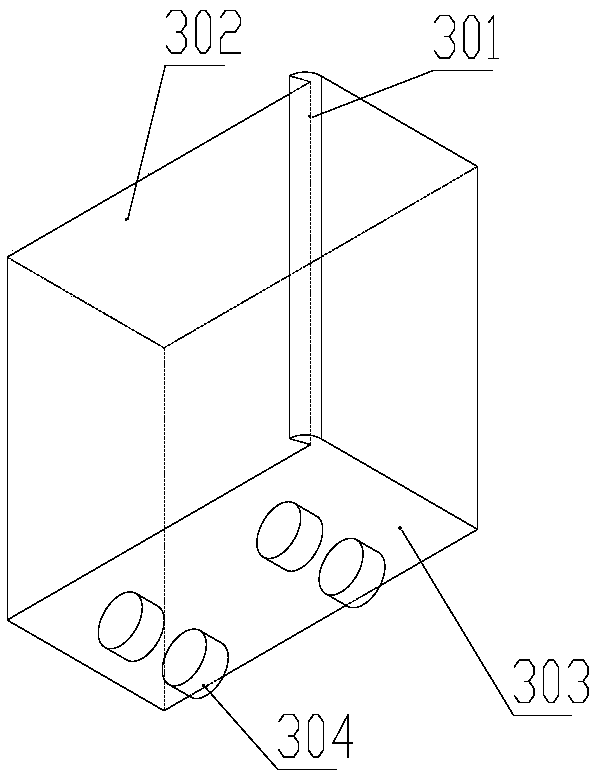

[0008] A mobile automatic steel pipe picking, cleaning, sorting and packaging device is composed of a picking device, a cleaning device, a sorting device, a packing device and a moving device. The picking device has a linear guide rail 1, a limit switch 2, a bracket 3, The structure of slide block 4, first gear 5, motor 6, rotating shaft 7, second gear 8, rack 9, fixed block 10, connecting column 11, electromagnetic chuck 12, clamping port 21 and horizontal cylinder 23, the described The cleaning device has a structure of a grinding wheel 13, a conveyor belt 14, an oil tank 15, an oil injection port 16, a vibrating screen 17, a vibrating plate 18 and a waste port 19, and the classification device has a first inclined plate 32, a second inclined plate 33, a second inclined plate The structure of three inclined plates 34, the first rack 35, the second rack 36, the third rack 37, the opening one 39, the opening two 38 and the baffle plate 40, the packing device has a movable suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com