Automobile safety mechanism

An automotive safety and automotive technology, applied in the direction of bumpers, etc., can solve the problems of small impact force, small force surface, short service life, etc., and achieve the effect of prolonging service life, improving bearing capacity, and improving anti-collision performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

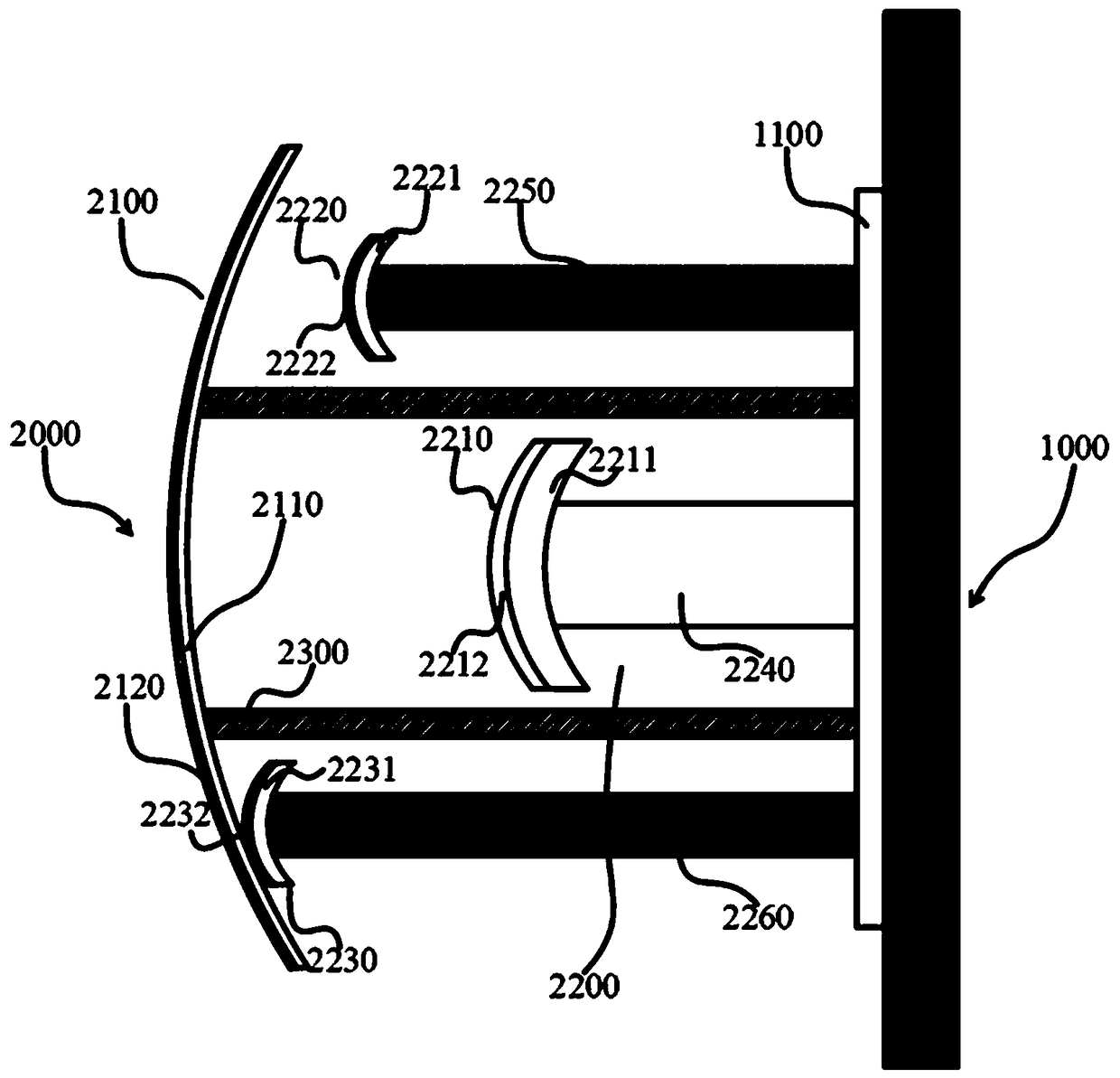

[0023] see figure 1 , an automobile safety mechanism, comprising: a vehicle body 1000, and an automobile front bumper 2000.

[0024] The body 1000 includes: a side member 1100 . The longitudinal beam 1100 is made of alloy material or metal material, with a width of 5-40 cm and a thickness of 1-10 cm; the longitudinal beam 1100 can be one or more, and can be arranged vertically or at an angle of 0-45 degrees to the vertical direction Angle setting.

[0025] The front bumper 2000 of the automobile comprises: a housing 2100 , a reinforcing device 2200 , and an elastic connector 2300 for the housing.

[0026] The casing 2100 includes: a casing body 2110 made of an alloy material, and a buffer layer 2120 made of a polymer material. The housing 2100 is elastically connected to the longitudinal beam 1100 through the housing elastic connector 2300; the buffer layer 2120 is fixedly connected or integrally formed with the housing main body 2110, and the fixed connection includes the ...

Embodiment 2

[0039] see figure 1 , an automobile safety mechanism, comprising: a vehicle body 1000, and an automobile front bumper 2000.

[0040] The body 1000 includes: a side member 1100 . The longitudinal beam 1100 is made of alloy material or metal material, with a width of 10 cm and a thickness of 3 cm; the longitudinal beam 1100 can be one or more, all of which are set in the vertical direction.

[0041] The front bumper 2000 of the automobile comprises: a housing 2100 , a reinforcing device 2200 , and an elastic connector 2300 for the housing.

[0042] The casing 2100 includes: a casing body 2110 made of an alloy material, and a buffer layer 2120 made of a polymer material. The housing 2100 is elastically connected to the longitudinal beam 1100 through the housing elastic connector 2300; the buffer layer 2120 is fixedly connected or integrally formed with the housing body 2110, and the fixed connection includes that the buffer layer 2120 is coated on the outer surface of the housi...

Embodiment 3

[0055] see figure 1 , an automobile safety mechanism, comprising: a vehicle body 1000, and an automobile front bumper 2000.

[0056] The body 1000 includes: a side member 1100 . The longitudinal beam 1100 is made of alloy material or metal material, with a width of 5 cm and a thickness of 1 cm; there are two longitudinal beams 1100, which are parallel to each other and set at an angle of 20 degrees to the vertical direction.

[0057] The front bumper 2000 of the automobile comprises: a housing 2100 , a reinforcing device 2200 , and an elastic connector 2300 for the housing.

[0058] The casing 2100 includes: a casing body 2110 made of an alloy material, and a buffer layer 2120 made of a polymer material. The housing 2100 is elastically connected to the longitudinal beam 1100 through the housing elastic connector 2300; the buffer layer 2120 is fixedly connected or integrally formed with the housing body 2110, and the fixed connection includes that the buffer layer 2120 is coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com