Special-shaped expansion block molded surface numerical control milling fixture and machining method

A CNC milling and block-expanding technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem of high processing costs, increased parts processing costs, positioning, clamping, alignment, and tool setting. High integration requirements and other issues, to achieve the effect of easy loading and unloading of parts, ensuring consistency, and low manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the above.

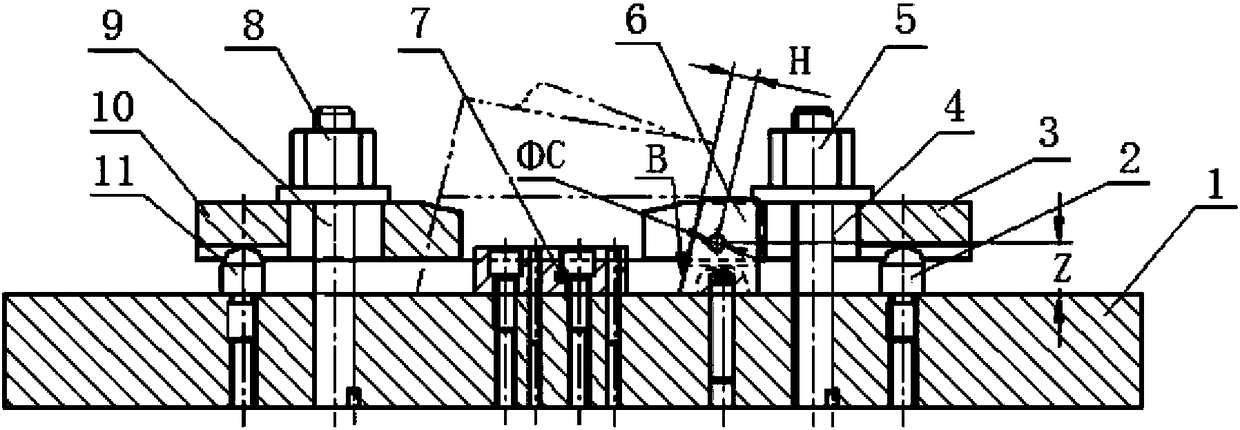

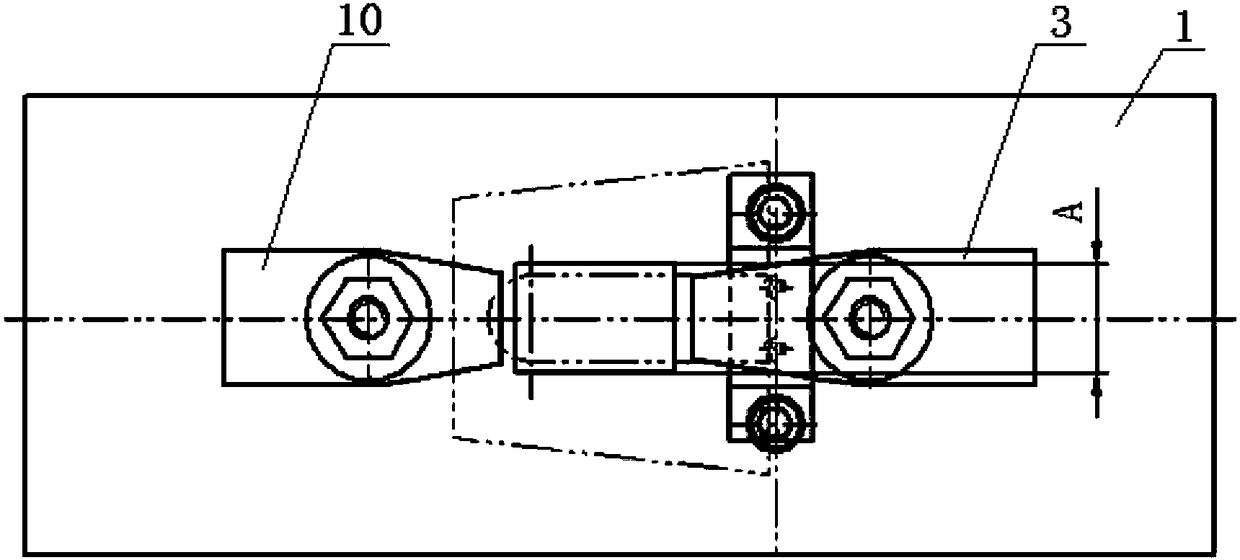

[0029] Such as figure 1 , figure 2 As shown, the CNC milling fixture for special-shaped expansion block surface according to the present invention includes a bottom plate 1, a right support 2, a right pressure plate 3, a left pressure plate 10, and a left support 11. The right pressure plate 3 is installed by a right screw 4 On the bottom plate 1, the right support 2 is installed between the bottom plate 2 and the right pressure plate 3, and is located on the right side of the right screw 4; the left pressure plate 10 is installed on the bottom plate 1 through the left screw 9, and the left support 2 is installed on the bottom plate 2 and Between the left pressure plate 10 and on the right side of the left screw 9, a positioning block 6 is also provided inside the right pressure plate 3. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com