High-elasticity electroluminescent fiber and preparation method thereof

An electroluminescent fiber, high-elasticity technology, applied in electroluminescent light sources, electric light sources, luminescent materials, etc., can solve the problems of difficult fabric integration, inflexibility of light-emitting diodes, and high device cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

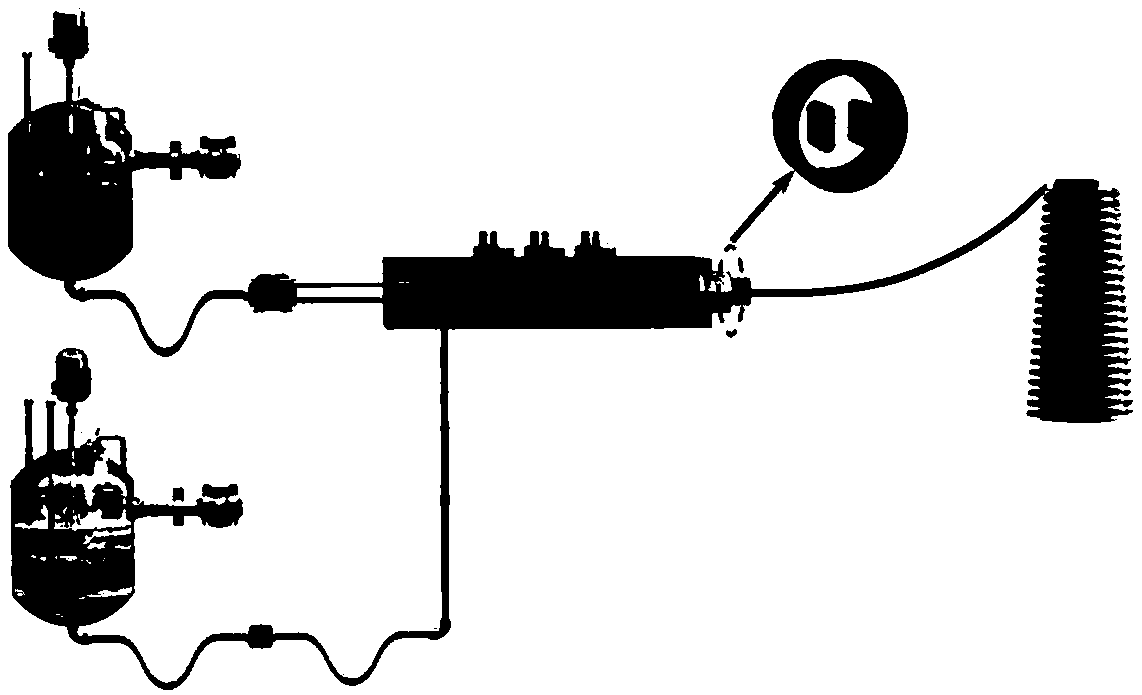

Method used

Image

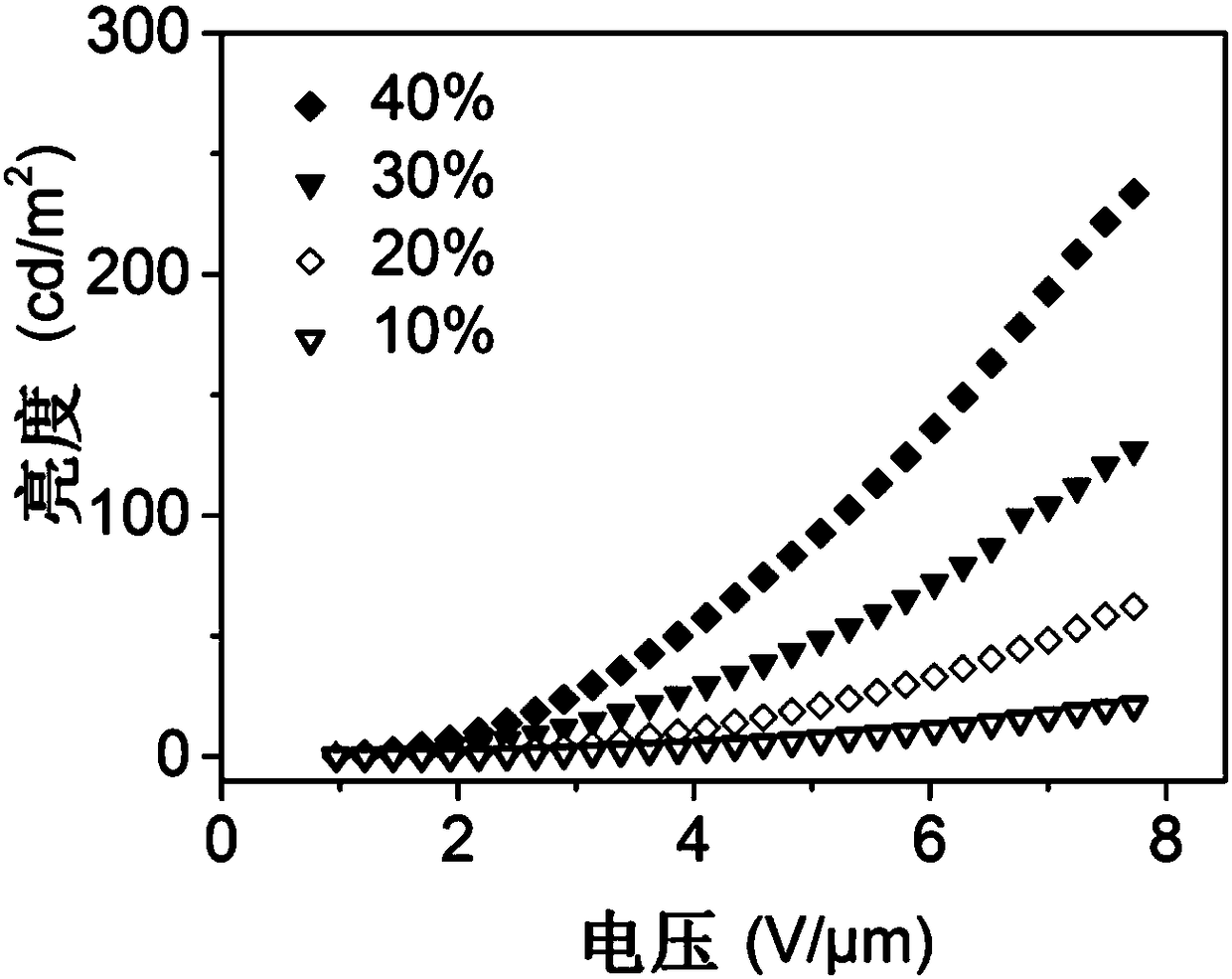

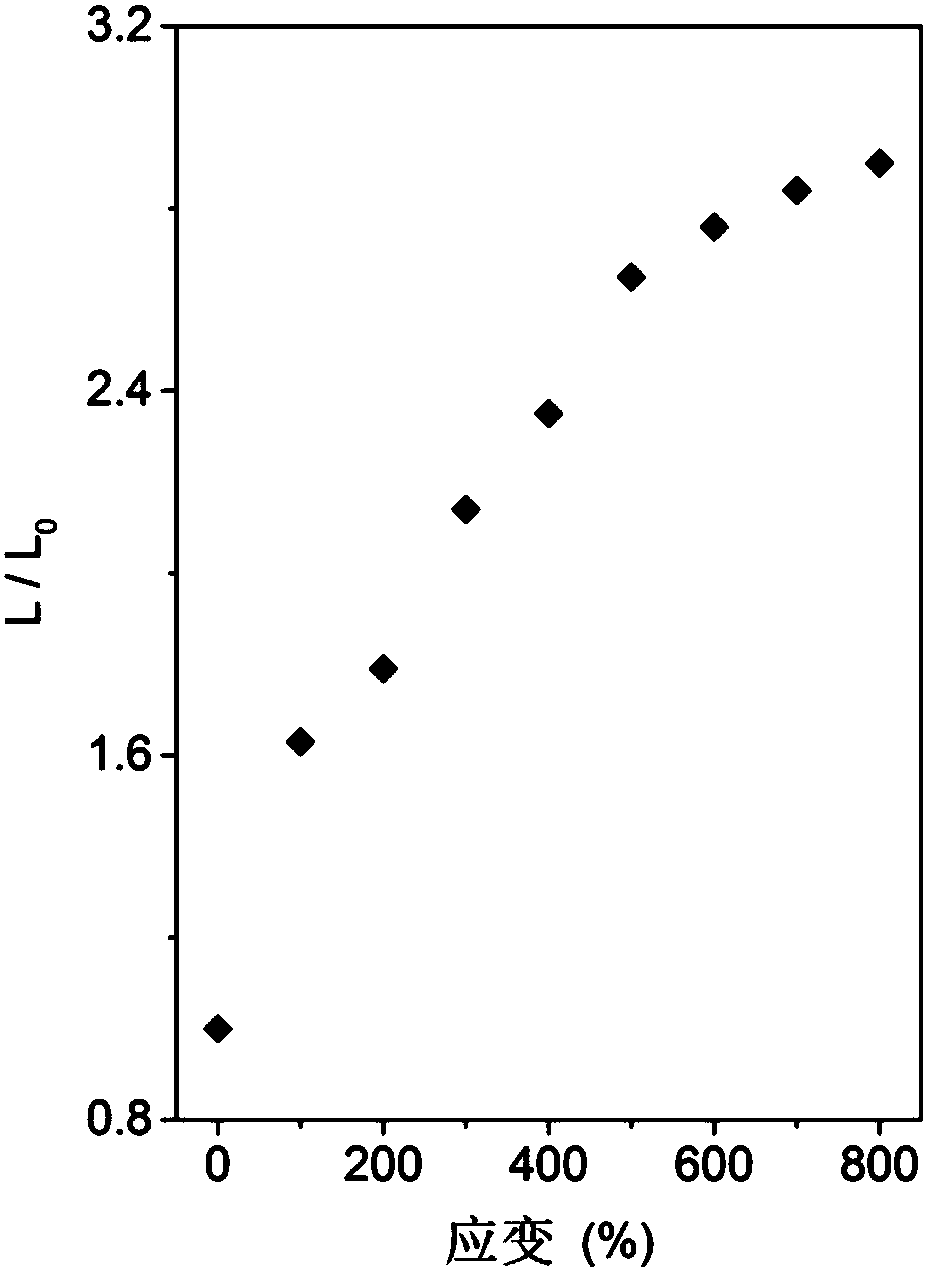

Examples

Embodiment Construction

[0025] Below in conjunction with specific implementation case, exemplary explanation and help further understanding of the present invention, but the specific details of implementation case are only for illustrating the present invention, do not represent all technical solutions under the present invention concept, therefore should not be interpreted as the overall technical scheme of the present invention The limitation of the technical solution, some insubstantial additions and changes that do not deviate from the concept of the present invention in the eyes of a skilled person, such as simple replacement or replacement of technical features with the same or similar technical effects, all belong to the protection scope of the present invention.

[0026] Gel ion conductor precursor solution preparation: dissolve polyvinyl alcohol and polyethylene oxide in water, the mass ratio is polyvinyl alcohol: polyethylene oxide: water = 1: 0.1: 10, heat and stir to fully dissolve, and Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com