Unsymmetrically loading tunnel construction method

A technology for tunnel construction and tunneling, which is used in tunnels, tunnel linings, and earth-moving drilling and mining, etc., can solve problems such as affecting the accuracy of tunnel support parameters, deviations, and lack of construction experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

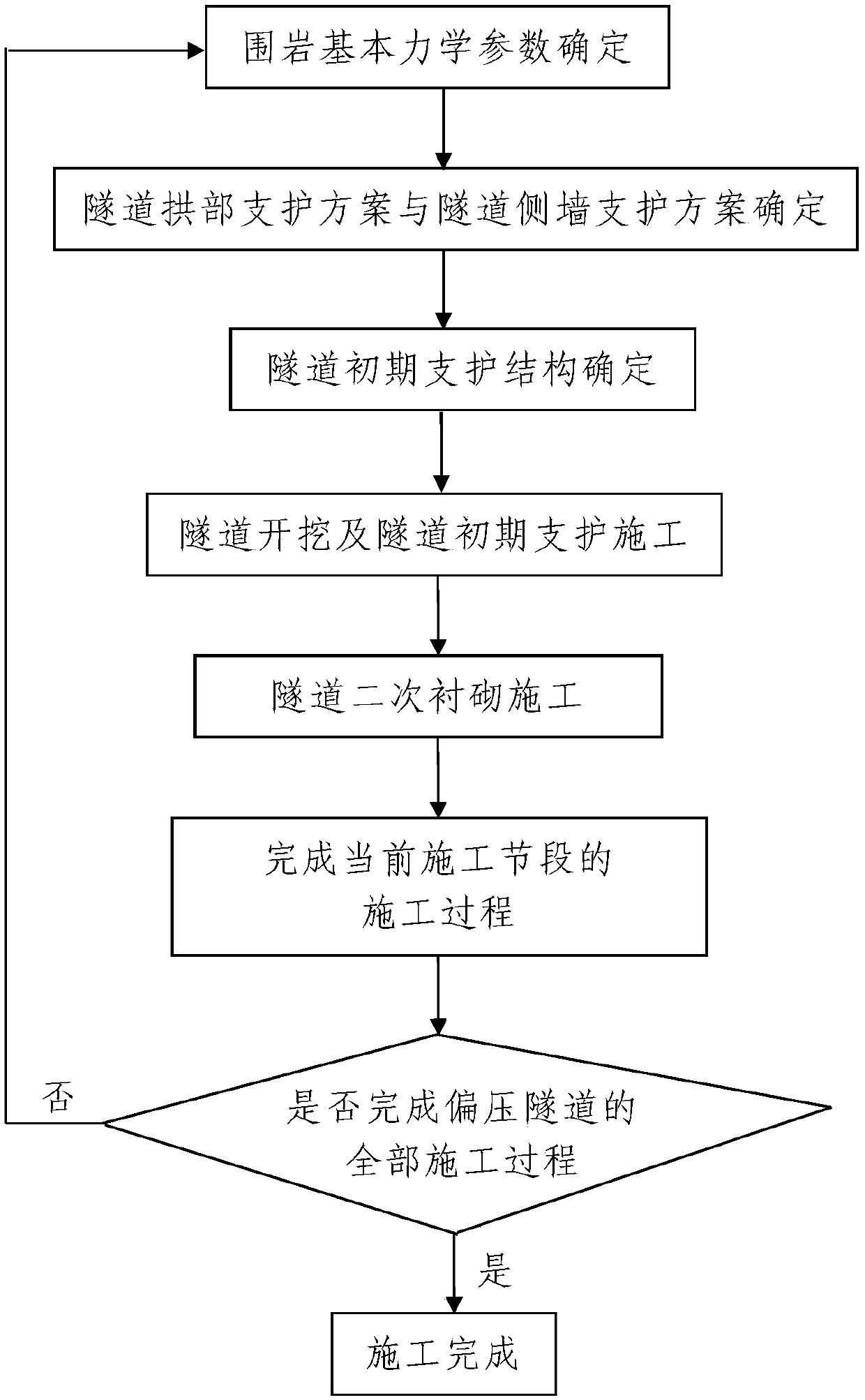

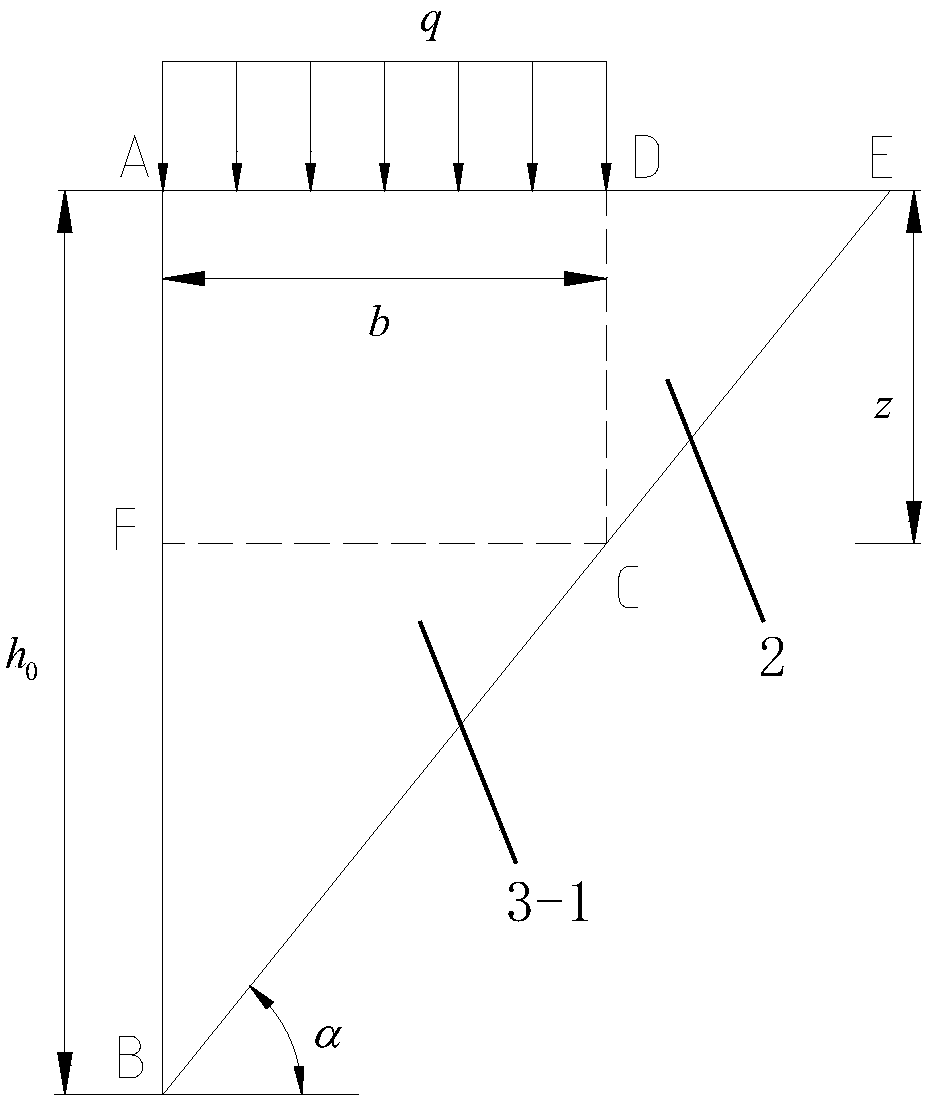

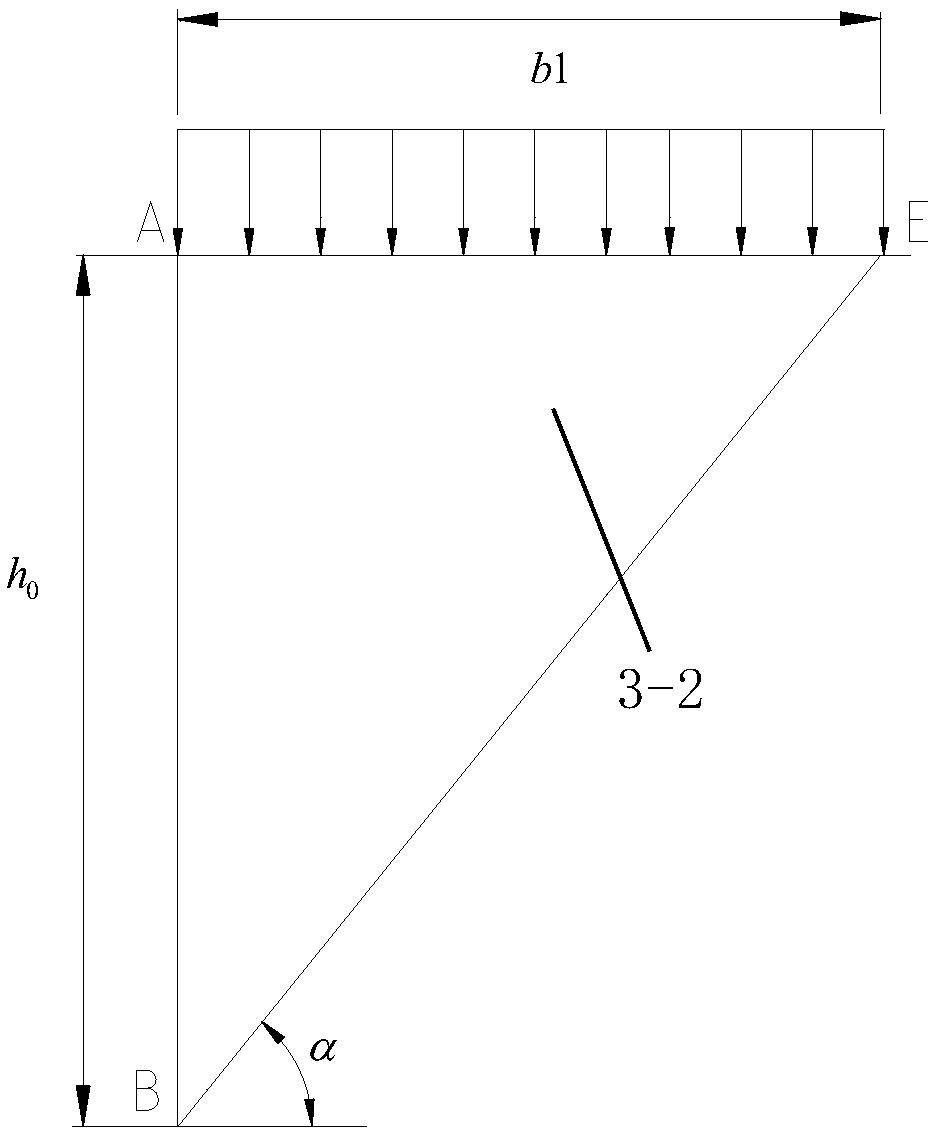

[0074] Such as figure 1 The construction method of a biased tunnel shown is characterized in that: the biased tunnel 1 is constructed in a plurality of sections from the back to the front along the longitudinal extension direction of the tunnel, and the construction methods of the plurality of sections are the same; The bias tunnel 1 is a soft rock tunnel and it is a shallow buried tunnel. The buried depth of one side of the bias tunnel 1 is H1 and the buried depth of the other side is H2, wherein H1 is the tunnel of one side of the bias tunnel 1 The vertical height from the top of the side wall to the ground, H2 is the vertical height from the top of the side wall of the other side of the bias tunnel 1 to the ground, H1<H2, H2<2B, where B is the excavation width of the bias tunnel 1 , the units of H1, H2 and B are all m; when constructing any segment, the following steps are included:

[0075] Step 1. Determination of the basic mechanical parameters of the surrounding rock:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com