Construction process of cement emulsified asphalt mortar penetrating semi-rigid road surface

A technology of cement emulsified asphalt and construction technology, applied in the field of road construction and maintenance, can solve problems such as extensive technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

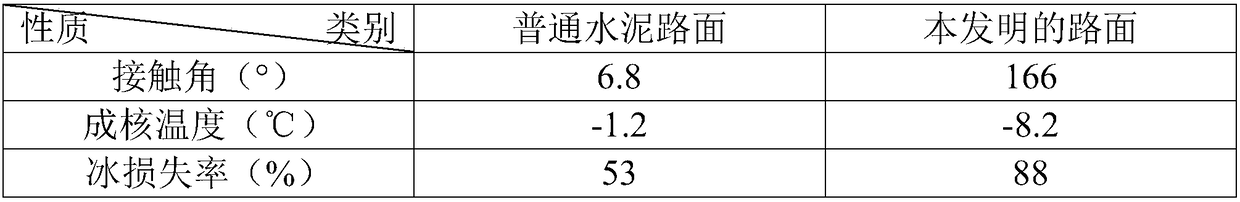

Embodiment 1

[0063] A construction technique for cement-emulsified asphalt mortar penetrating semi-rigid pavement, comprising the following steps:

[0064] 1. Formation of cement emulsified asphalt mortar penetration type main structure;

[0065] 2. The roughening treatment of the formed main structure road surface;

[0066] 3. Laying the adhesive layer: apply the adhesive to the roughened road surface to form an adhesive layer;

[0067] 4. Lay the anti-slip and wear-resistant layer: before the adhesive material is dried and solidified, spread the anti-slip and wear-resistant material on the adhesive layer, and after drying for 2-3 hours, proceed to the next step;

[0068] 5. Coating anti-icing layer: After stirring the anti-icing coating evenly, roll it onto the anti-skid and wear-resistant layer;

[0069] 6. Heating and curing: After the anti-icing coating layer is dried for 1.0-1.5 hours, use the road surface dryer to heat and cure it, that is, complete the construction treatment of t...

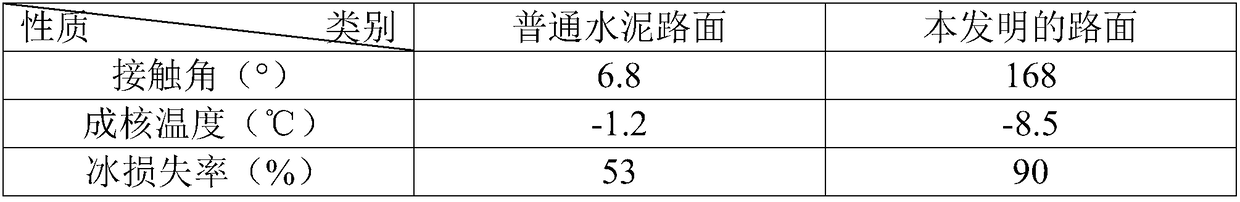

Embodiment 2

[0116] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0117] The binder is a mixture of the following raw materials by weight: 500 parts of polyacrylic resin, 200 parts of vinyl acrylate, 150 parts of high-viscosity anti-rutting particles, 50 parts of sodium bicarbonate, 45 parts of emulsifier, 9 parts of initiator, toluene 7 parts of diisocyanate, 20 parts of dimethyl sulfoxide, 15 parts of yellow dextrin, 3 parts of sodium hypochlorite, 3 parts of hydrogen peroxide and 200 parts of water; the emulsifier is castor oil ethylene oxide adduct and its derivatives, The initiator is diisopropyl peroxydicarbonate.

[0118] The composition of the high-viscosity anti-rutting particles is 50 parts of nano-tungsten particles, 50 parts of nano-zirconium particles, 30 parts of white carbon black, 15 parts of grafted starch, 15 parts of diatomite composite material, 15 parts of active volcanic ash, polyphenylene sulfide 10 parts of ether and 10 parts of glyce...

Embodiment 3

[0123] Embodiment 3 is basically the same as Embodiment 1, and its difference is:

[0124]The binder is a mixture of the following raw materials by weight: 400 parts of polyacrylic resin, 175 parts of vinyl acrylate, 125 parts of high-viscosity anti-rutting particles, 40 parts of sodium bicarbonate, 40 parts of emulsifier, 6 parts of initiator, 5 parts of toluene diisocyanate, 15 parts of dimethyl sulfoxide, 12 parts of yellow dextrin, 2 parts of sodium hypochlorite, 2 parts of hydrogen peroxide and 150 parts of water; the emulsifier is castor oil ethylene oxide adduct and its derivatives , the initiator is diisopropyl peroxydicarbonate.

[0125] The composition of the high-viscosity anti-rutting particles is 40 parts of nano-tungsten particles, 40 parts of nano-zirconium particles, 25 parts of white carbon black, 12 parts of grafted starch, 12 parts of diatomite composite material, 13 parts of active volcanic ash, polyphenylene sulfide 9 parts of ether and 9 parts of glycery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com