Magnesium alloy surface blue self pore sealing ceramic layer and preparation method

A technology of ceramic layer and magnesium alloy, applied in the field of preparation of blue micro-arc oxidation ceramic layer, can solve the problem of less development work of blue micro-arc oxidation ceramic layer on magnesium surface, and achieve excellent corrosion resistance and mechanical properties, corrosion resistance Excellent physical and mechanical properties, and the effect of enhancing protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

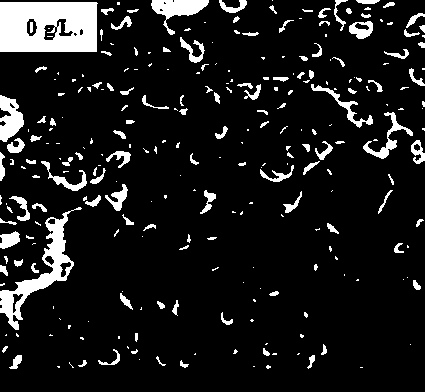

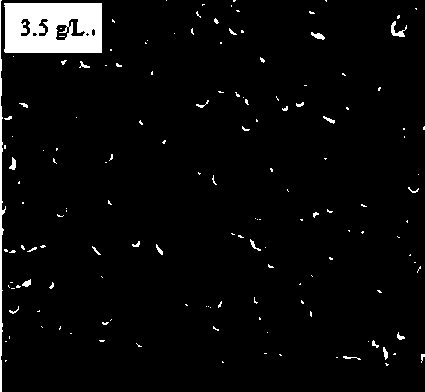

[0029] In this embodiment, the blue self-sealing hole micro-arc oxidation ceramic layer on the surface of the magnesium alloy, that is, after adding a certain amount of K 2 TiF 6 The micro-arc oxidation ceramic layer was prepared in the electrolyte, so that a ceramic layer doped with Ti element was formed in situ on the surface of the magnesium alloy substrate, and the thickness was 10 μm.

[0030] The preparation method of the magnesium alloy blue self-sealing micro-arc oxidation ceramic layer includes the following steps:

[0031] Step 1: After degreasing and degreasing the wire-cut magnesium alloy sample, it is ground with different water sandpaper, and then washed with water after polishing to prepare for micro-arc oxidation treatment.

[0032] Step 2: Prepare the silicate-based micro-arc oxidation electrolyte according to the matching principle of the micro-arc oxidation electrolyte, where K 2 TiF 6 The concentration is 3.5 g / L;

[0033] Step 3: Use a DC pulse micro-a...

Embodiment 2

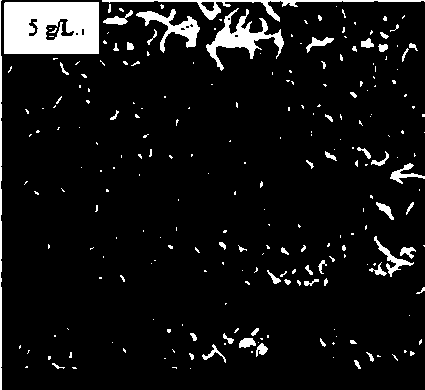

[0036] In this embodiment, the blue self-sealing hole micro-arc oxidation ceramic layer on the surface of the magnesium alloy, that is, after adding a certain amount of K 2 TiF 6 A micro-arc oxidation ceramic layer was prepared in the electrolyte, so that a magnesium oxide porous film doped with Ti was formed on the surface of the magnesium alloy substrate in situ, and the thickness of the ceramic layer was 10 μm.

[0037] The preparation method of the magnesium alloy blue self-sealing micro-arc oxidation ceramic layer includes the following steps:

[0038] Step 1: After degreasing and degreasing the wire-cut magnesium alloy sample, it is ground with different water sandpaper, and then washed with water after polishing to prepare for micro-arc oxidation treatment.

[0039] Step 2: Prepare the silicate-based micro-arc oxidation electrolyte according to the matching principle of the micro-arc oxidation electrolyte, where K 2 TiF 6 The concentration is 5 g / L;

[0040] Step 3:...

Embodiment 3

[0043] In this embodiment, the blue self-sealing hole micro-arc oxidation ceramic layer on the surface of the magnesium alloy, that is, after adding a certain amount of K 2 TiF 6 The micro-arc oxidation ceramic layer was prepared in the electrolyte, so that a ceramic layer doped with Ti element was formed in situ on the surface of the magnesium alloy substrate, and the thickness was 10 μm.

[0044] The preparation method of the magnesium alloy blue self-sealing micro-arc oxidation ceramic layer includes the following steps:

[0045] Step 1: After degreasing and degreasing the wire-cut magnesium alloy sample, it is ground with different water sandpaper, and then washed with water after polishing to prepare for micro-arc oxidation treatment.

[0046] Step 2: Prepare the silicate-based micro-arc oxidation electrolyte according to the matching principle of the micro-arc oxidation electrolyte, where K 2 TiF 6 The concentration is 10 g / L;

[0047] Step 3: Use a DC pulse micro-ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com