Magnesia carbon brick and preparation method thereof

A magnesia-carbon brick and carbon technology, which is applied in the field of magnesia-carbon bricks and its preparation, can solve the problems of insufficient adaptability of magnesia-carbon bricks, and achieve the effects of good resistance, improved service life, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

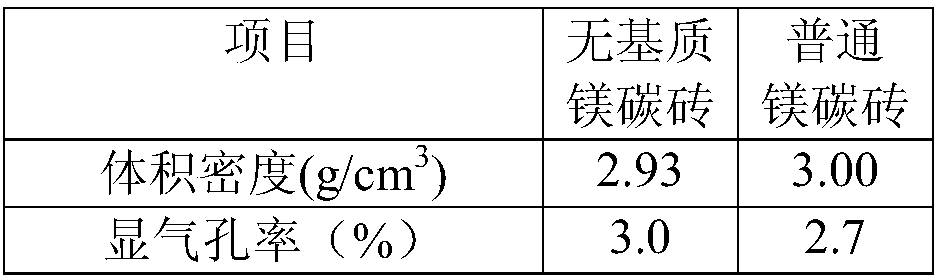

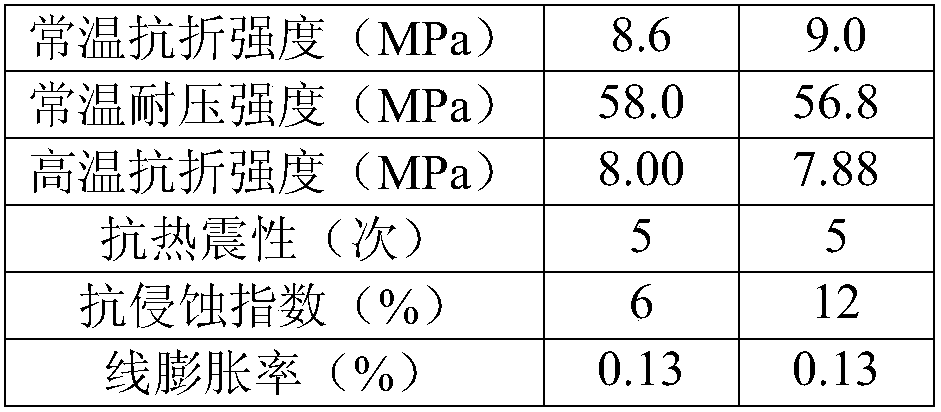

Image

Examples

Embodiment 1

[0020] A magnesia-carbon brick, comprising components by weight percentage: 85% of fused magnesia particles, 8% of carbon, 5% of additives, and 2% of binder.

[0021] (1) Mixing: Mixing is carried out with a rotary circulating mixer, and the fused magnesia particles, carbon, additives, and binders are weighed according to the ratio of raw materials, and the fused magnesia particles are first put into the mixing Dry mix in the machine for 5 minutes, then add binder and continue mixing for 5 minutes, then add carbon to it, mix for 8 minutes, finally add additives and continue mixing for 10 minutes to form mud, the speed of the mixer is set at 970r / min;

[0022] (2) Compression molding: add the mud material that has been mixed into the mold and use a compound friction brick press to perform compression molding to make bricks, and the pressure is 3000KN;

[0023] (3) Baking and curing: put the adobe in a tunnel-type drying kiln to bake and cure, the baking temperature is 200° C., ...

Embodiment 2

[0025] A magnesia-carbon brick, comprising components by weight percentage: 90% of fused magnesia particles, 5% of carbon, 2% of additives, and 3% of binder.

[0026] (1) Mixing: Mixing is carried out with a rotary circulating mixer, and the fused magnesia particles, carbon, additives, and binders are weighed according to the ratio of raw materials, and the fused magnesia particles are first put into the mixing Dry mix in the machine for 8 minutes, then add binder and continue mixing for 10 minutes, then add carbon to it, mix for 10 minutes, finally add additives and continue mixing for 8 minutes to form mud, the speed of the mixer is set at 980r / min;

[0027] (2) Compression molding: add the mud material that has been mixed into the mold and use a compound friction brick press to perform compression molding to make bricks, and the pressure is 3500KN;

[0028] (3) Baking and curing: the bricks are baked and cured in a tunnel-type drying kiln at a temperature of 200° C. for 20 ...

Embodiment 3

[0030] A magnesia-carbon brick, comprising components by weight percentage: 84% of fused magnesia particles, 10% of carbon, 4% of additives, and 2% of binder.

[0031] (1) Mixing: Mixing is carried out with a rotary circulating mixer, and the fused magnesia particles, carbon, additives, and binders are weighed according to the ratio of raw materials, and the fused magnesia particles are first put into the mixing Dry mix in the machine for 10 minutes, then add binder and continue mixing for 8 minutes, then add carbon to it, mix for 12 minutes, finally add additives and continue mixing for 12 minutes to form mud, the speed of the mixer is set at 970r / min;

[0032] (2) Compression molding: add the mud material that has been mixed into the mold and use a compound friction brick press to perform compression molding to make bricks, and the pressure is 4000KN;

[0033] (3) Baking and curing: put the adobe in a tunnel-type drying kiln to bake and cure, the baking temperature is 250° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com