Self-closed type outlet device of liquid container

A technology for an outlet device and a liquid container, which is applied in the field of liquid packaging containers and liquid containers, can solve the problems of increasing packaging costs, wasting packaging resources, and being unfavorable for resource recovery, and achieves the effect of preventing chronic damage and preventing resource waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

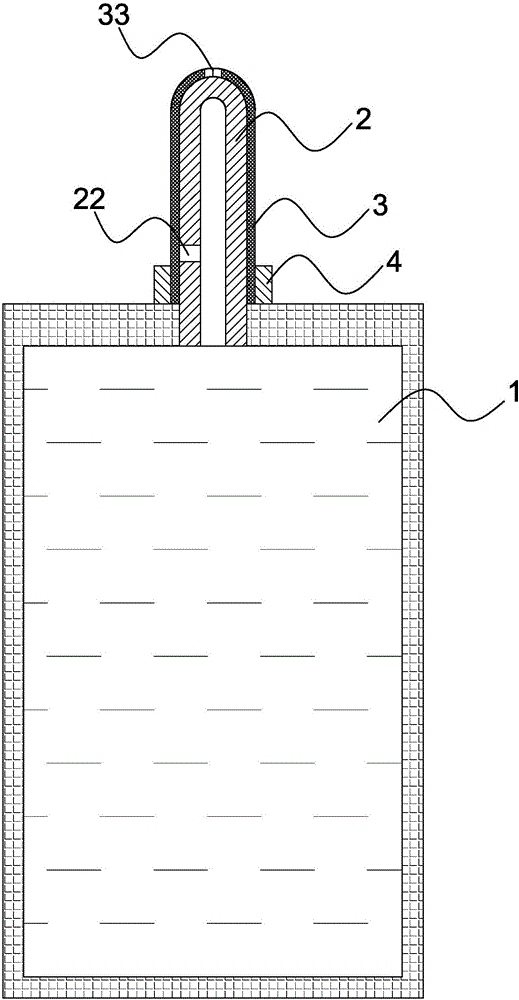

[0013] like figure 1 As shown, (1) represents a pouch made of flexible plastic material with sterile liquid inside, (2) represents a tube core made of hard plastic, the tube core (2) and the capsule Bag (1) air-tight fixed connection. The figure shows that the tube core (2) is plastic-sealed on one side of the pouch (1), and the inner cavity of the tube core and the inner cavity of the pouch are communicated with each other. Other common fixed connection methods can also be used or the tube core and the pouch are integrally formed, which are all existing technologies and can be achieved by technical personnel in the industry without creative work. The top end of the tube core (2) is closed, and a through hole (22) is opened on the side wall thereof. (3) represents a sleeve made of elastic rubber material, one end of which is open, and the other end is closed to open an incision (33). closure. The sleeve (3) is tightly sleeved on the outer surface of the tube core (2) and c...

specific Embodiment 2

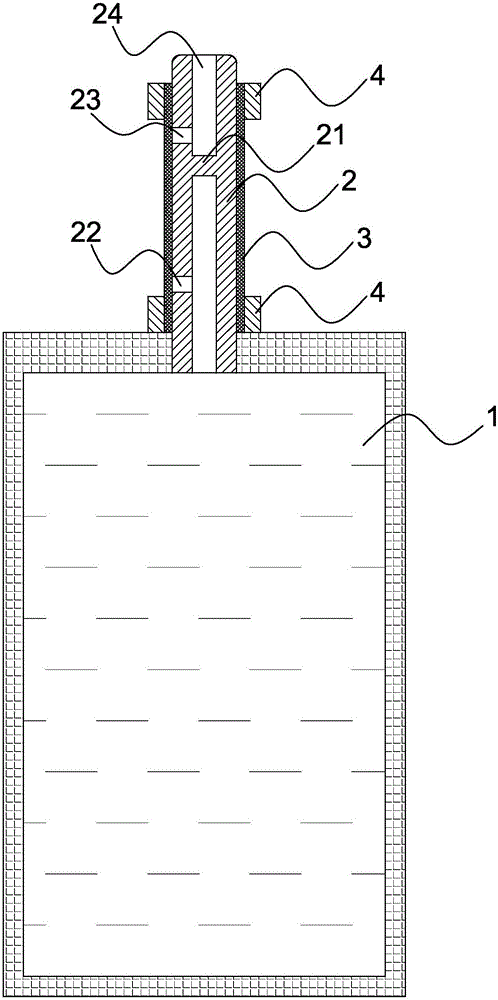

[0014] like figure 2 As shown, (1) represents a pouch made of flexible plastic material with sterile liquid inside, (2) represents a tube core made of hard plastic, the tube core (2) and the capsule Bag (1) air-tight fixed connection. The figure shows that the tube core (2) is plastic-sealed on one side of the pouch (1), and the inner cavity of the tube core and the inner cavity of the pouch are communicated with each other. Other common fixed connection methods can also be used or the tube core and the pouch are integrally formed, which are all existing technologies and can be achieved by technical personnel in the industry without creative work. A separator (21) is airtightly enclosed near the outlet end (24) of the tube core (2), and the side between the end of the tube core (2) connected to the container (1) and the separator (21) A first through hole (22) is opened on the wall, and a second through hole (23) is opened on the side wall between the outlet end (24) of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com