Phosphogypsum water hard road material and preparation method thereof

A technology of road materials and gypsum water, which is applied in the field of road engineering construction, can solve problems such as damage to soil structure and connection, poor crack resistance, pollution, etc., and achieve high orderly arrangement, high water erosion resistance, and high chemical stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

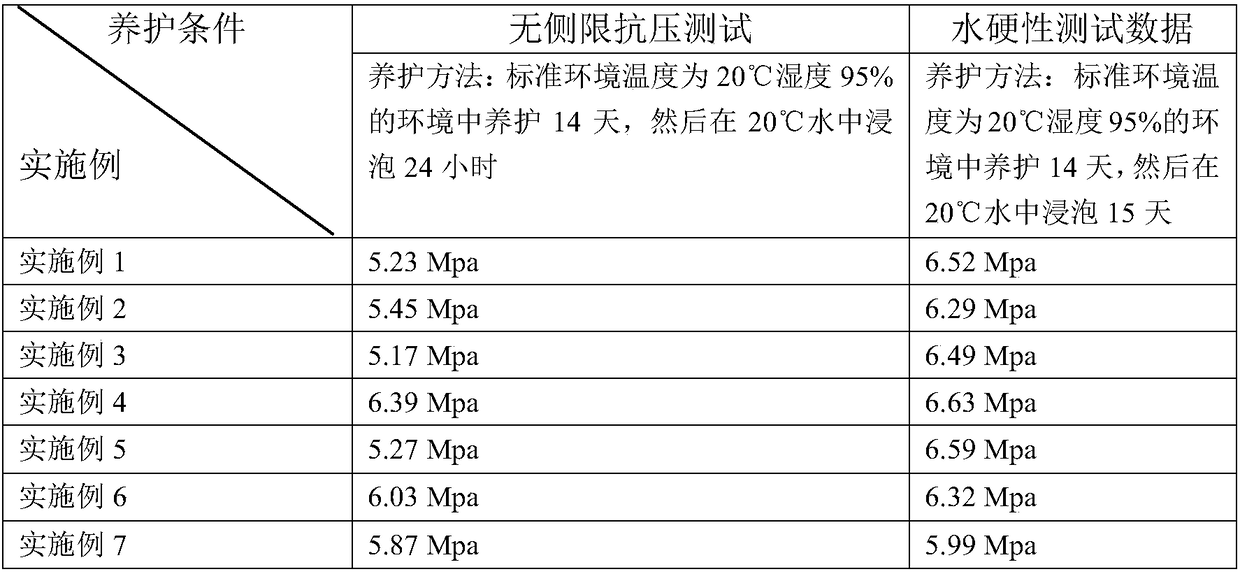

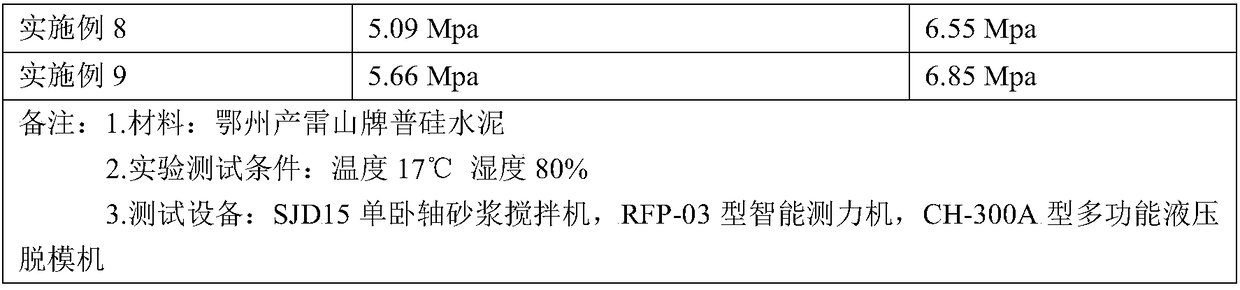

Examples

Embodiment 1

[0043] Embodiment 1: a kind of phosphogypsum hydraulic road material, described road material is made of the raw material of following percentage by weight: phosphogypsum 78%, lime 6% cement 15.2%, curing agent 0.8%, described curing agent is made of the following substances Aqueous solution configured according to mass fraction:

[0044] Cationic Chelate 3%

[0045] Nano Zirconia 0.03%

[0046] Ethylenediamine 0.1%

[0049] Triethanolamine 1%

[0051] The balance is water,

[0052] Wherein, the cationic chelate is a metal ion chelate formed by chelating magnesium ions and ethylenediaminetetraacetic acid (EDTA).

Embodiment 2

[0053] Embodiment two: a kind of phosphogypsum hydraulic road material, described road material is made of the raw material of following percentage by weight: phosphogypsum 77%, steel slag 8%, cement 14.3%, curing agent 0.7%, described curing agent consists of the following Aqueous solution composed of substances according to mass fraction:

[0054] Cationic Chelate 4%

[0055] Nano Zirconia 0.035%

[0056] Ethylenediamine 0.15%

[0058] Naphthalenesulfonic acid formaldehyde condensate 3%

[0060] Sodium Alkylbenzene Sulfonate 1%

[0061] The balance is water,

[0062] Wherein, the cationic chelate is a metal ion chelate formed by chelating magnesium ions and aminotriacetic acid (NTA).

Embodiment 3

[0063] Embodiment three: a kind of phosphogypsum hydraulic road material, described road material is made of the raw material of following percentage by weight: phosphogypsum 80%, aluminum slag 5%, lime 1%, cement 13.4%, curing agent 0.6%, so The aqueous solution in which the curing agent is configured by the following substances according to the mass fraction:

[0064] Cationic Chelate 5%

[0065] Nano Zirconia 0.01%

[0066] Nano Titanium Dioxide 0.01%

[0067] Ethylenediamine 0.05%

[0068] Paraformaldehyde 0.07%

[0071] Chromium Sulfate 3%

[0072] Naphthalenesulfonic acid formaldehyde condensate 2%

[0073] Polyvinyl alcohol 0.8%

[0074] Dimethylaniline 2%

[0076] Sodium Alkylbenzene Sulfonate 1%

[0077] The balance is water,

[0078] Wherein, the cationic chelate is a metal ion chelate formed by chelating calcium ions and ethylenediaminetetraacetic acid (EDTA).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com