Slitting device used for thin film slitting machine

A technology of film slitting and slitting knives, which is applied in the direction of thin material processing, transportation and packaging, and sending objects, etc. It can solve the problems of not being able to cut the film, the film cannot meet the required specifications, and affect the quality of the product, so as to reduce waste , to avoid the effect of sliding knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

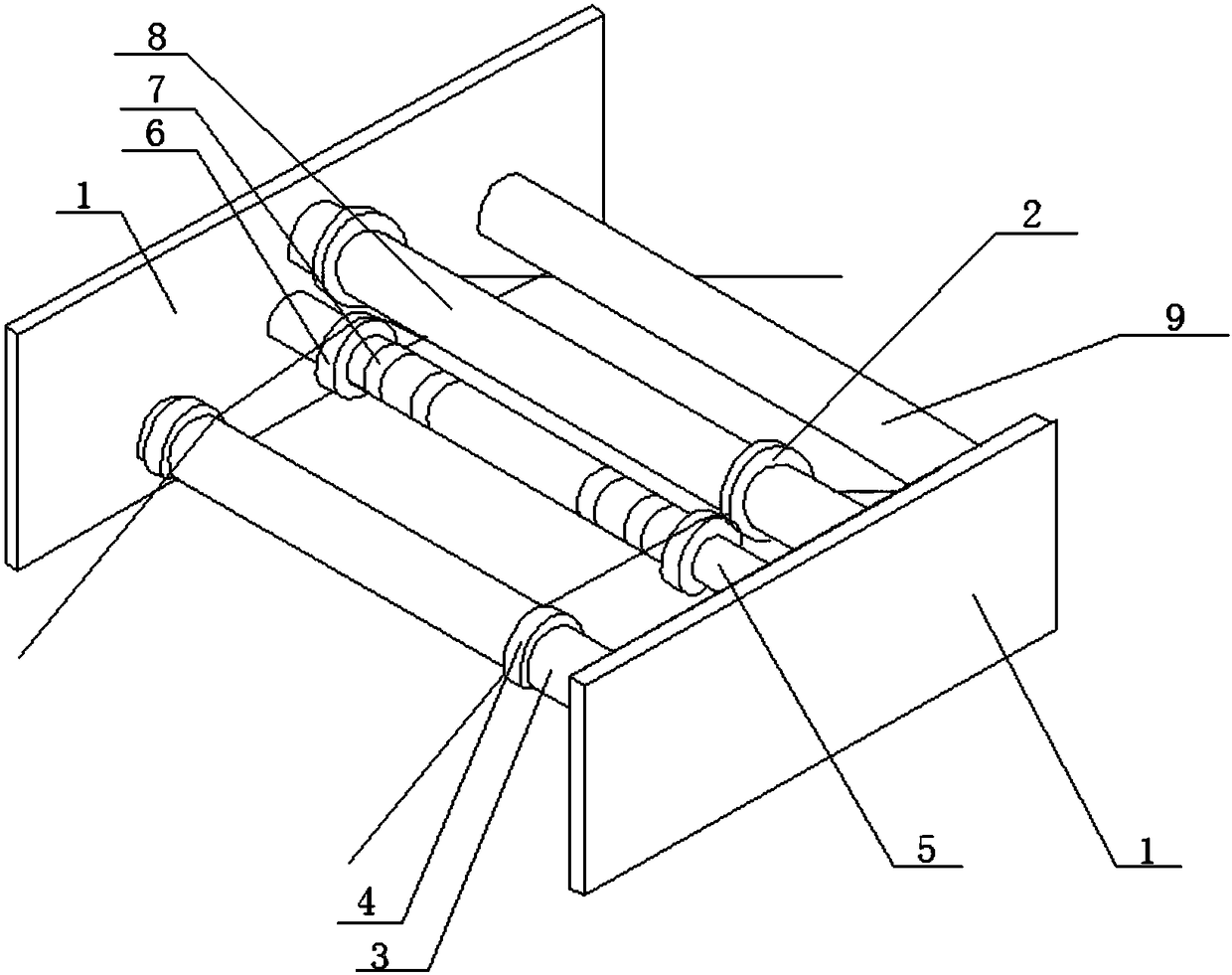

[0022] see figure 1 , the application provides a cutting device for a film slitting machine, comprising two opposite fixed plates 1;

[0023] Between the two fixed plates 1, a first transmission guide wheel 3, a sipe wheel transmission shaft 5 and a cutting shaft 8 parallel to each other are arranged;

[0024] The height of the first transmission guide wheel 3 is the same as that of the sipe wheel transmission shaft 5;

[0025] A cutting shaft 8 is provided above the sieve drive shaft 5;

[0026] Both ends of the sipe drive shaft 5 are respectively provided with sipe wheels 6;

[0027] The sipe wheel 6 is sleeved on the sipe wheel transmission shaft 5;

[0028] Several grooves 7 are provided on the sipe wheel transmission shaft 5, and the grooves 7 are used to clip the sipe wheel 6;

[0029] Two tool holders 2 are sleeved on the cutting shaft 8;

[0030] Each of the knife holders 2 is mounted with a cutting knife.

[0031] The working principle of this embodiment is: the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com