Round bottle labelling machine provided with plate pressing mechanism

A labeling machine and platen technology, applied in the direction of labeling machine, labeling, labeling, etc., can solve the problems of insufficient efficiency, affecting operation efficiency, poor accuracy, etc., achieve reasonable design, compact structure, improve labeling accuracy and efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

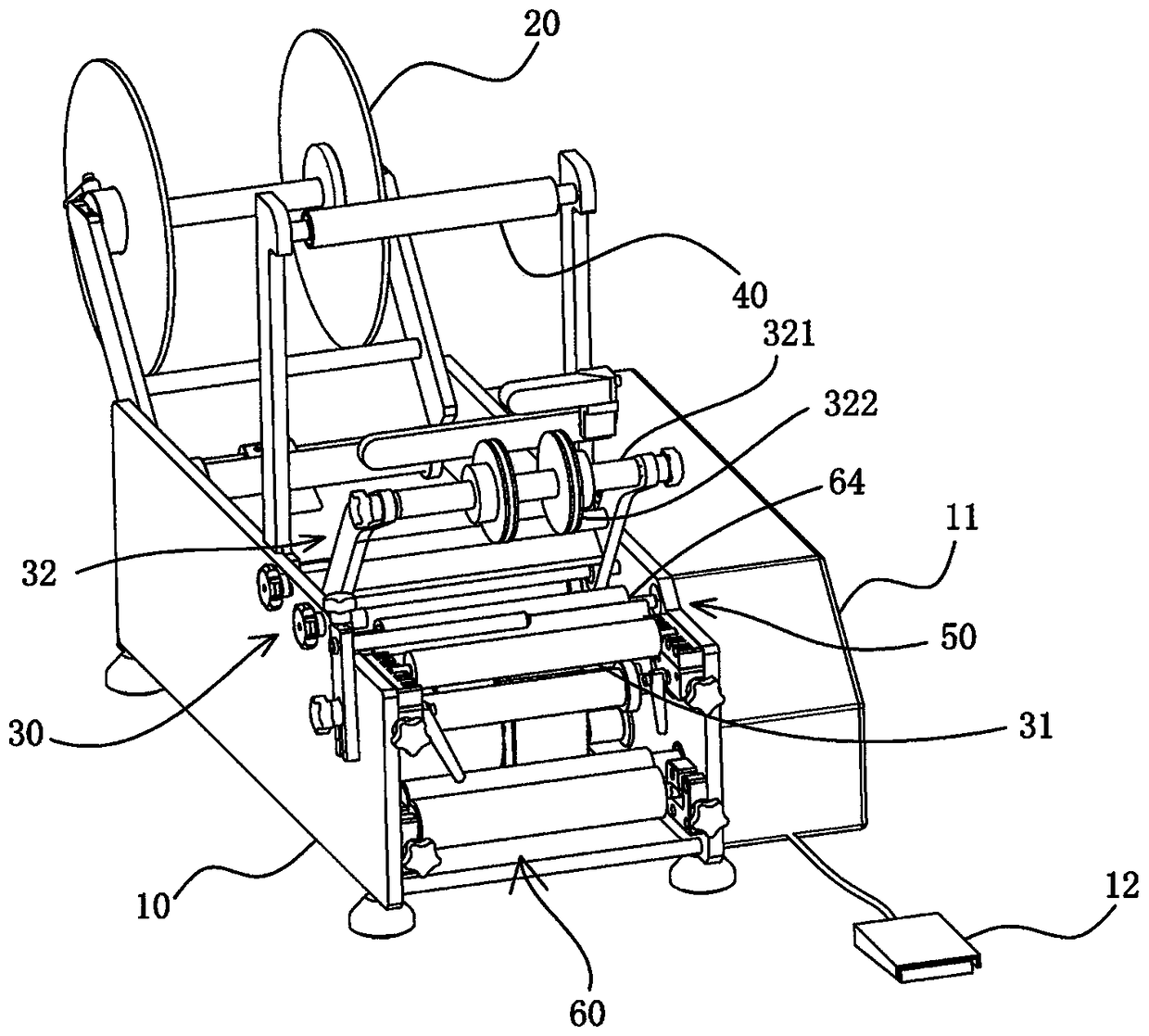

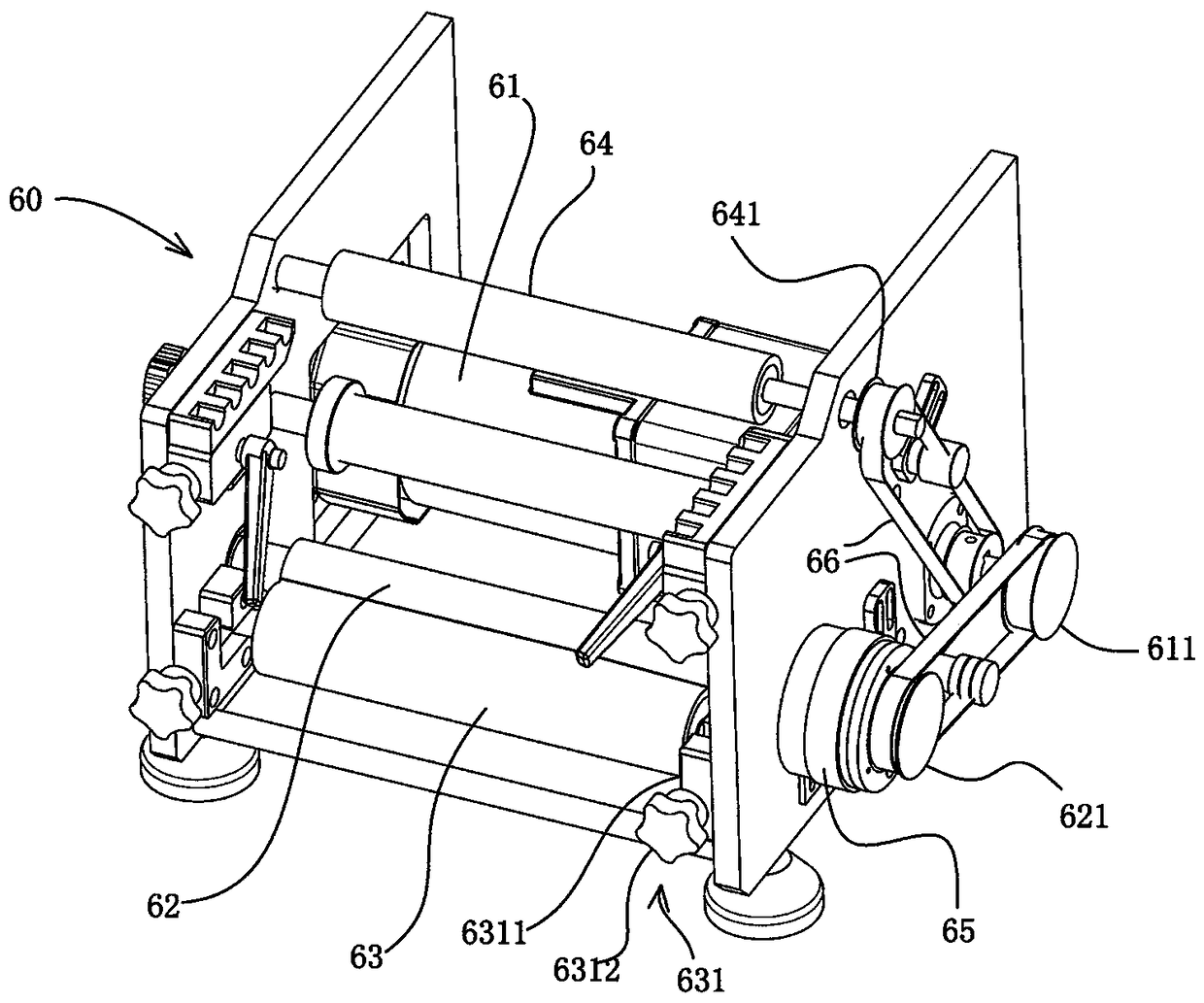

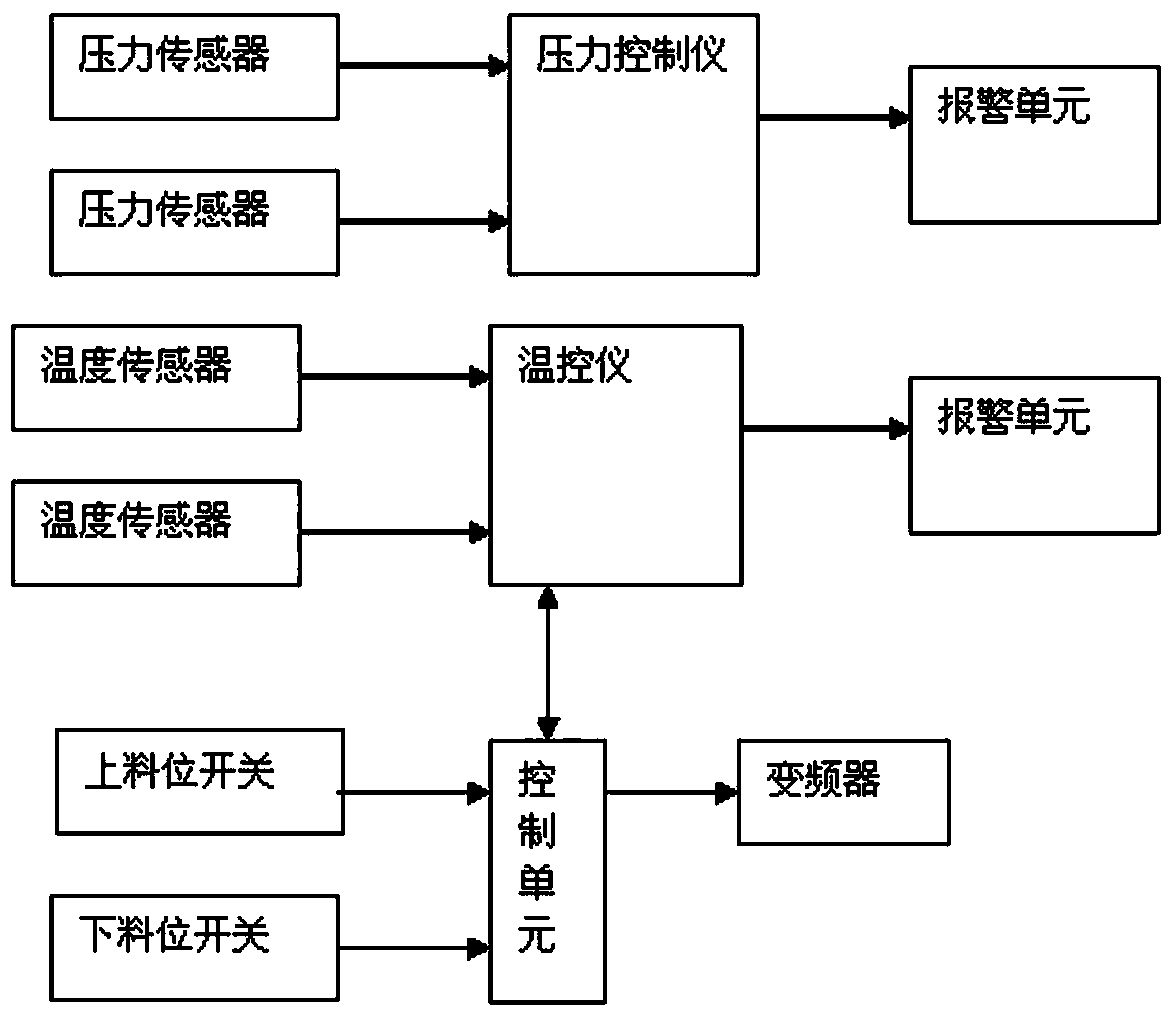

[0016] according to Figure 1~3 The specific structure of the present invention will be described in detail. The round bottle labeling machine with a platen mechanism includes a cabinet 10, a label feeding mechanism 20, a bottle holding device 30 for clamping a round bottle that needs to be pasted with a label, a sensor 40 for detecting the position of the label, The label stripping device 50 and the clutch traction device 60 for pasting labels are provided with a control electric box 11 on the side of the cabinet 10. The clutch traction device 60 includes a motor 61, a traction driving wheel shaft 62, a traction driven wheel shaft 63, a driving shaft 64 and a clutch 65 . Wherein feeding mechanism, bottle supporting device 30, sensor 40, label stripping device 50 are known feeding mechanism, bottle supporting device 30, sensor 40, label stripping device 50 for labeling machine. The clutch traction device 60 includes a motor 61 , a traction driving wheel shaft 62 , a traction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com