Handheld pneumatic lining press mounting gun

A bushing and press-fitting technology, which is applied in the field of crimping tools for machinery manufacturing, can solve the problems of difficulty in ensuring axial verticality, manual control is difficult, and a discharge mechanism is required, so as to achieve convenient handheld operation space and weight. Light, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

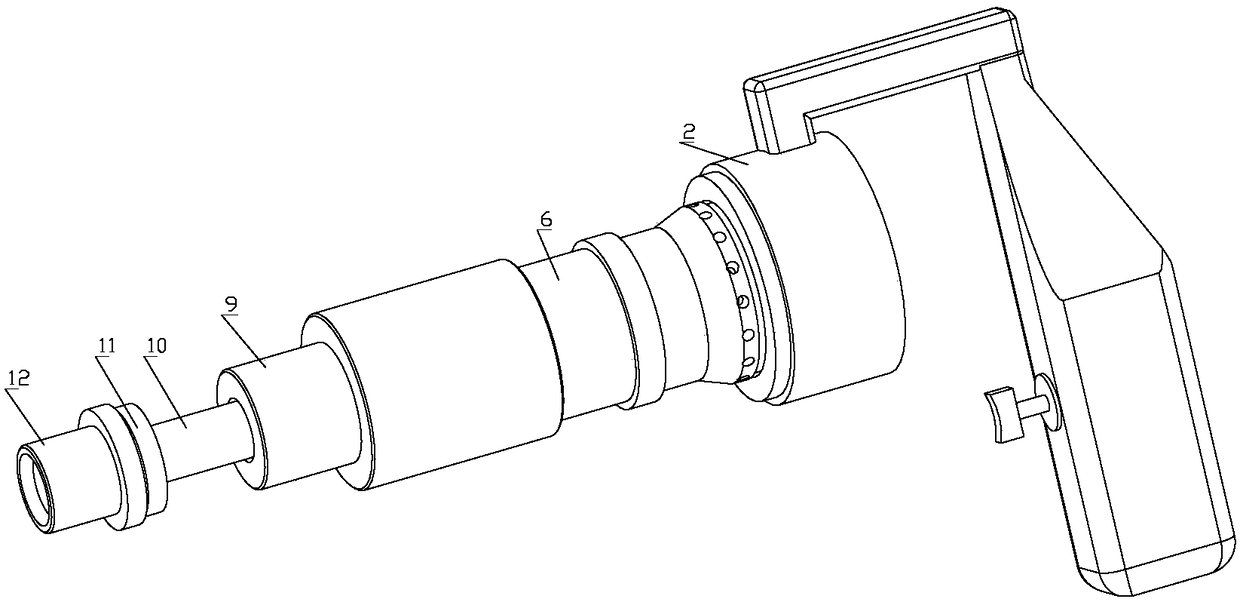

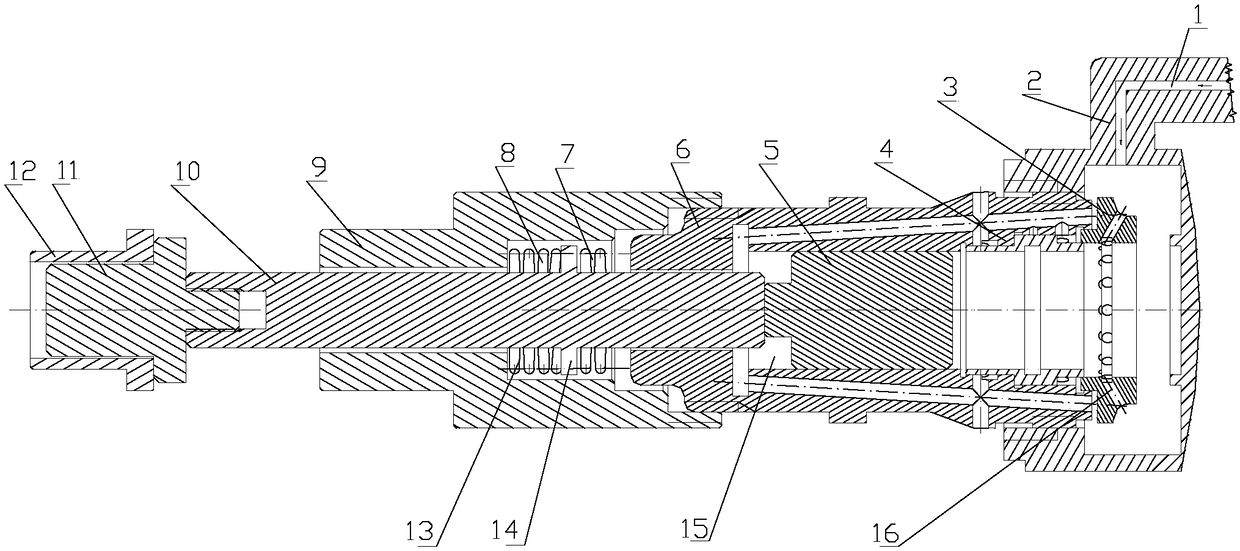

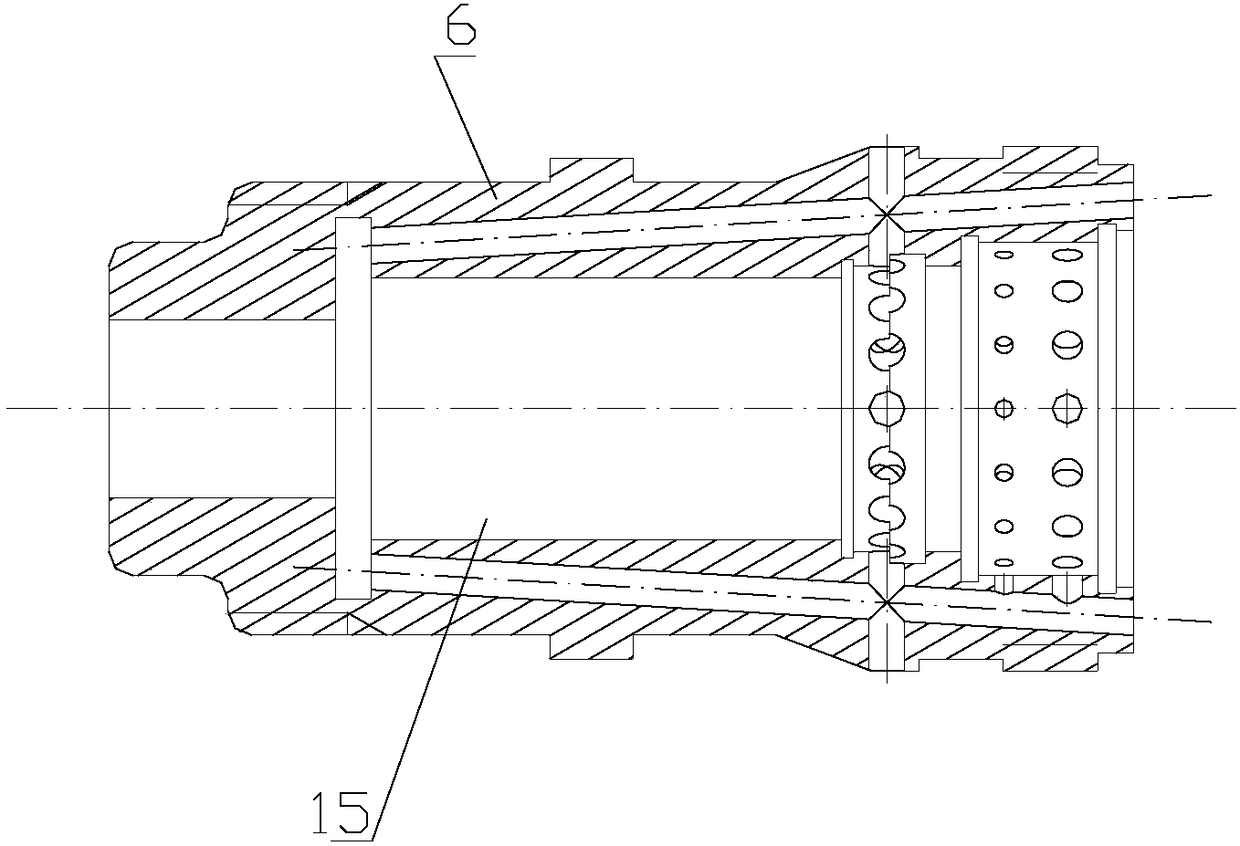

[0017] refer to Figure 1-Figure 4 . In the embodiment described below, a hand-held pneumatic liner press gun has a gun body with an air inlet passage, and the air inlet passage 1 with a barrel handle 2 communicates with the air chamber of the barrel end cover, and the high pressure The air flow is divided into two paths, one of which gathers energy through the circular array oblique hole at the tail of the end cover 3, drives the end cover 3 to rotate, sends the Laval rotating air flow into the dynamic pressure chamber of the barrel, and the impact piston 5 passes through the piston bearing 6 along the barrel 9. The channel of the sliding pipe impacts the piston impact rod 10, and the other channel passes through the oblique hole of the conical gas cylinder 4, the bus bar of the conical array, and enters the end-to-end circular array hole of the piston bearing 6, forming a Laval high-pressure concentrated air flow that impacts the spring seat of the piston impact rod, forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com