Motor

A motor and iron core technology, applied in the field of motors, can solve the problems such as the deterioration of the roundness of the inner peripheral surface of the iron core cage, the inability to install heat sinks, and the increase of cogging torque, so as to suppress the deterioration of the roundness and achieve good rigidity. , the effect of reducing cogging torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

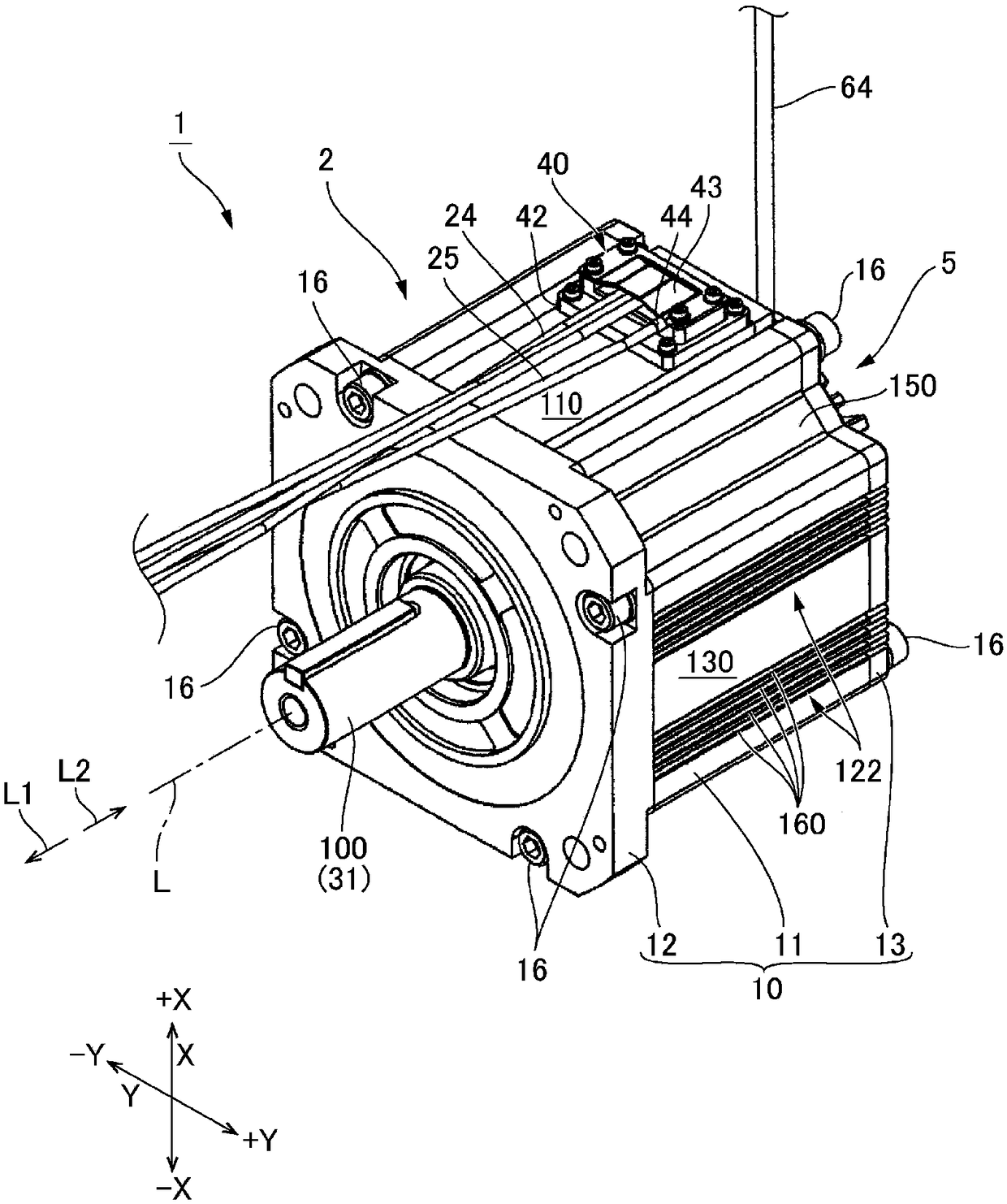

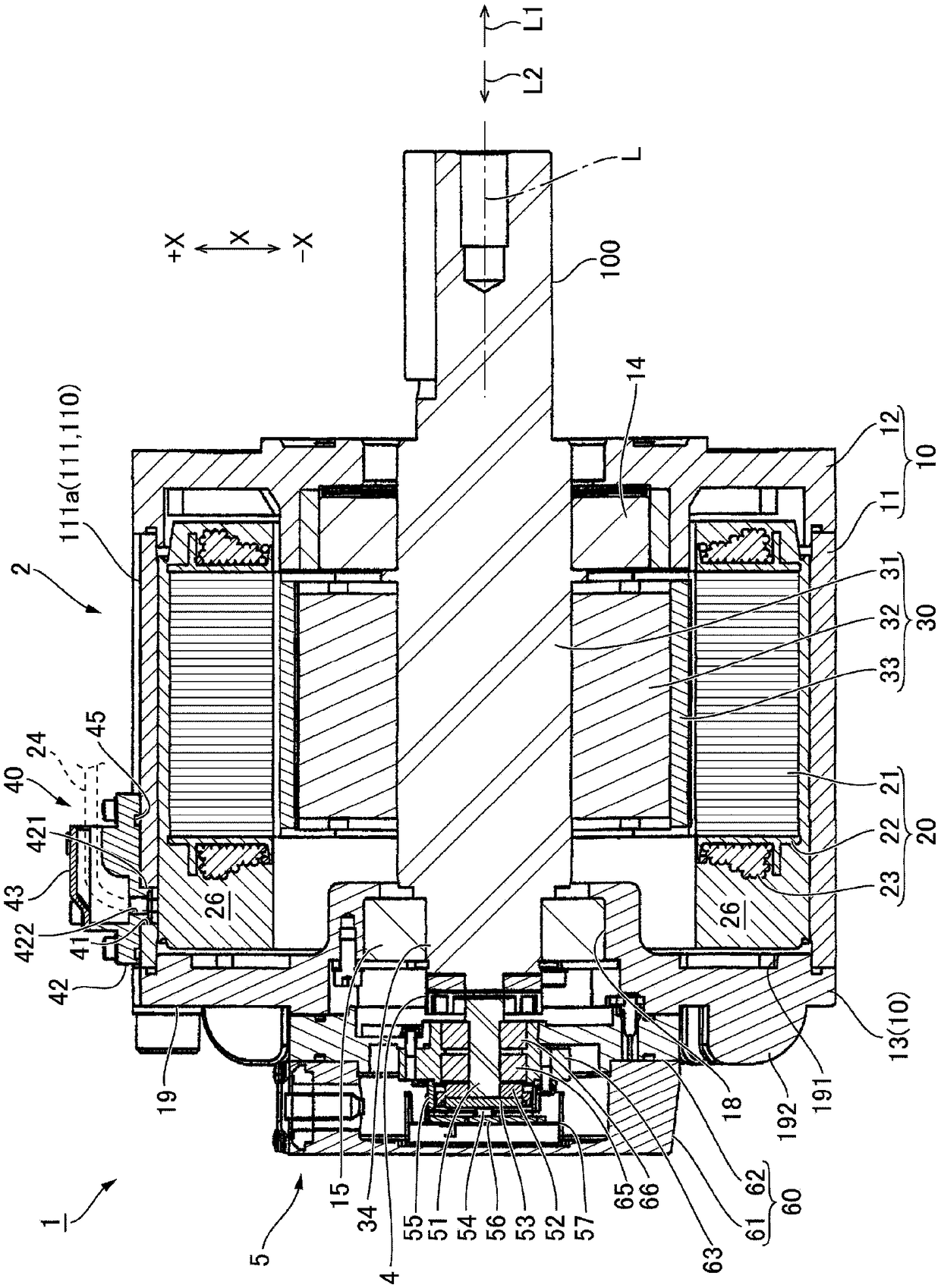

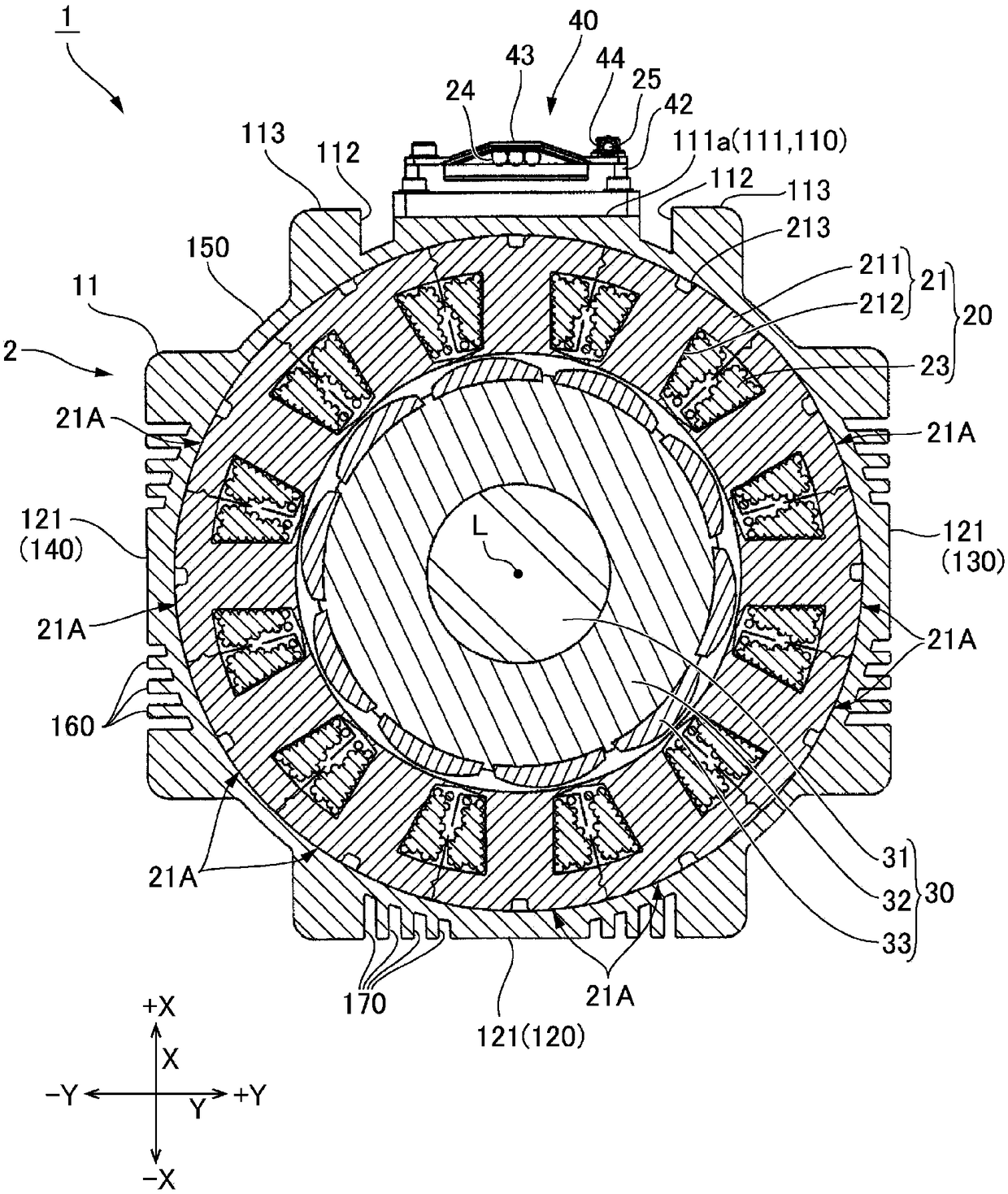

[0030] Embodiments of a motor to which the present invention is applied will be described below with reference to the drawings. figure 1 is an external perspective view of the motor 1 according to the present invention viewed from the output side, figure 2 This is a cross-sectional view obtained by cutting the motor 1 along a plane parallel to the axial direction L. As shown in FIG. and, image 3 This is a cross-sectional view obtained by cutting the motor 1 along a plane perpendicular to the axial direction L. As shown in FIG. In this specification, the side where the output shaft 100 of the motor 1 protrudes out of the one side and the other side in the axial direction L of the motor 1 is referred to as the output side L1, and the side opposite to the side where the output shaft 100 protrudes is referred to as the output side L1. Output the opposite side L2. In addition, two directions perpendicular to the axial direction L are defined as the X direction and the Y direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com