Gas turbine blade defect three-dimensional space positioning method based on digital rays

A gas turbine blade and digital ray technology, which is applied in the direction of material analysis using radiation, can solve the problems of impenetrable blade penetration, high detection cost, and large ray attenuation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] see figure 1 , the present invention provides a digital ray nondestructive testing system based on a digital ray-based gas turbine blade defect three-dimensional space positioning method, including a system imaging device (flat panel detector), a turntable, an X-ray source and a computer, a system imaging device, a turntable and an X-ray The ray sources are all connected to the computer, and the computer controls the emission of the X-ray source. There are blades placed on the turntable, and the computer controls the movement of the turntable. The computer collects data from the images formed by the blades on the system imaging device.

[0074] A three-dimensional space positioning method for gas turbine blade defects based on digital rays of the present invention includes the following three aspects:

[0075] S1. Establishment of the system coordinate system

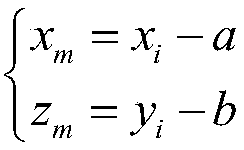

[0076] In order to accurately describe the defect and its three-dimensional position relative to the blade, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com