A lightweight, low-odor, low-voc, high-impact-strength, high-temperature-resistant PP honeycomb composite panel and its preparation method

A honeycomb composite board and low-odor technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of molded parts that are not full, PP honeycomb is easy to soften and collapse, corner deformation, etc. achieve strong competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

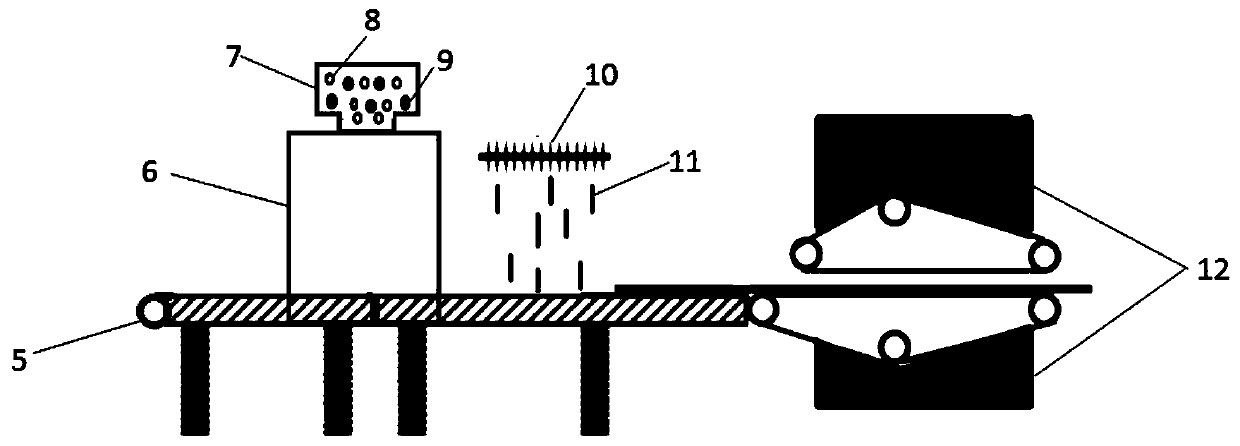

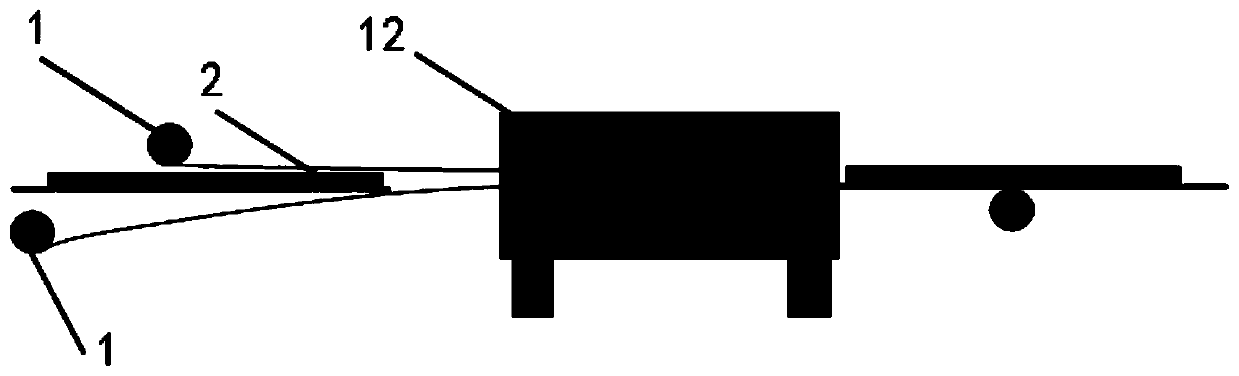

[0040] A lightweight, low-odor, low-VOC, high-impact, high-temperature-resistant PP honeycomb composite panel. The prepreg skin layer 1 is made of glass fiber, microspheres 9, and rubber powder 8 in a certain ratio of 45:1:54, which is compounded by heating and cooling. The glass fiber is chopped glass fiber, the length is 50mm, the rubber powder 8 is PP rubber powder 8, modified by PP wax, the melting index is high, and the melting index is 60g / 10min. figure 2 It is a schematic diagram of the CMT production method. The preparation method for the skin layer 1 of the high-initiation ultra-light and high-strength prepreg for PP honeycomb panels is to put the PP rubber powder 8 and the microspheres 9 into the high-speed mixing box 7, stir evenly, and pass through the electrostatic adsorption device. The electrostatic adsorption process of 6 is scattered on the conveyor belt of the transmission device, and then the glass fiber 11 falls freely and evenly on the mixed system of PP r...

Embodiment example 1

[0049] Implementation case 1 (6mm lightweight CMT solid board): weight 300g / m 2 ; Comparative example 1 (6mm traditional CMT solid plate): weight 900g / m 2 , The CMT of the present invention has the advantage of being lightweight.

Embodiment 2

[0051] A lightweight, low-odor, low-VOC, high-impact, high-temperature-resistant PP honeycomb composite panel. The prepreg skin layer 1 is composed of glass fiber, microspheres 9, and rubber powder 8 in a ratio of 49.5:1.5:49, which is compounded by heating and cooling The glass fiber is chopped glass fiber, the length is 40mm, the rubber powder 8 is PP rubber powder 8, modified by PP wax, the melting index is 80g / 10min, figure 2 It is a schematic diagram of the CMT production method. The preparation method for the skin layer 1 of the high-initiation ultra-light and high-strength prepreg for PP honeycomb panels is to put the PP rubber powder 8 and the microspheres 9 into the high-speed mixing box 7, stir evenly, and pass through the electrostatic adsorption device. The electrostatic adsorption process of 6 is scattered on the conveyor belt of the transmission device, and then the glass fiber 11 falls freely and evenly on the mixed system of PP rubber powder 8 and microspheres ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com