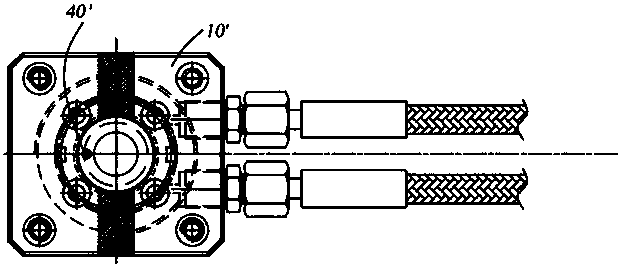

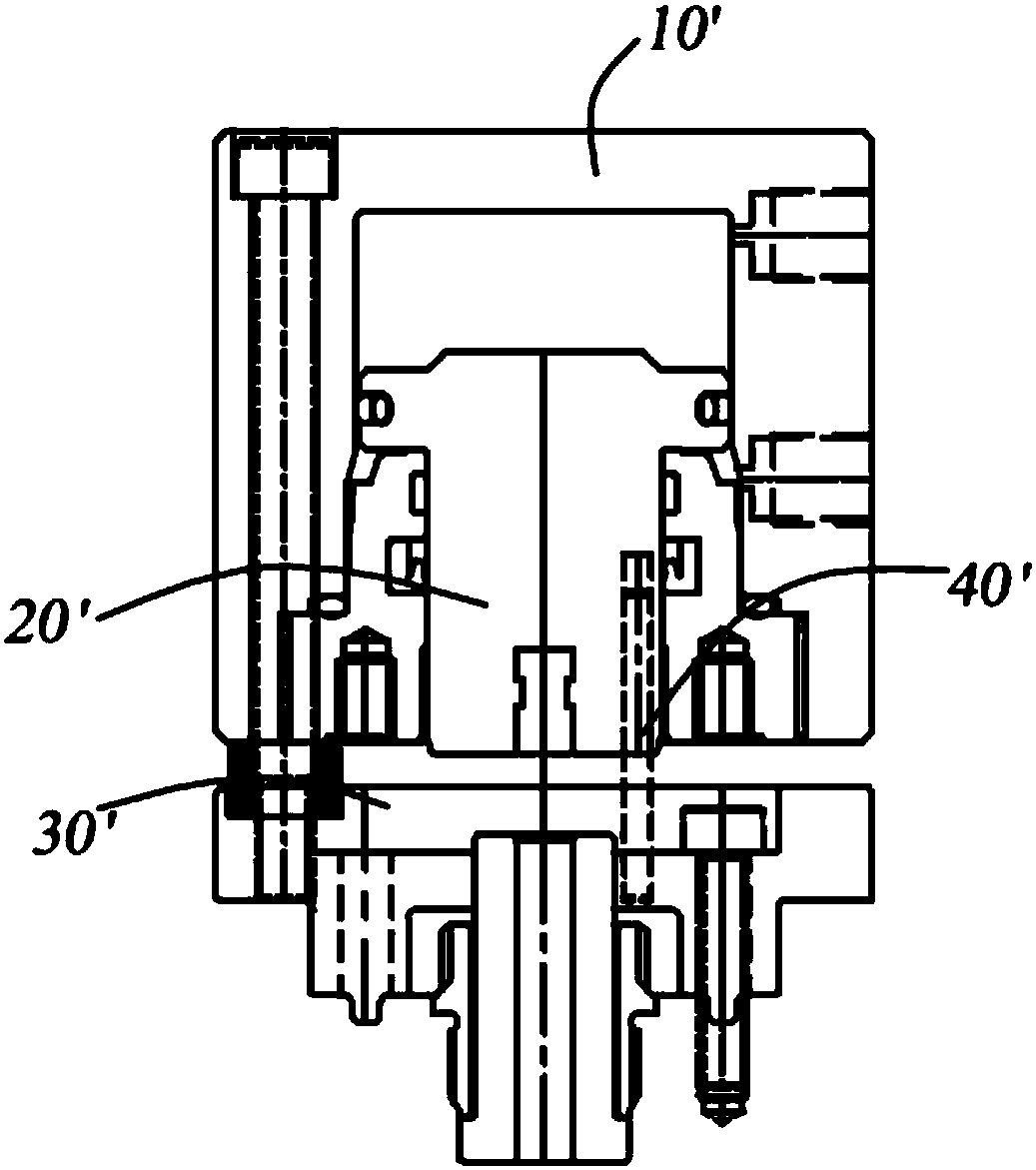

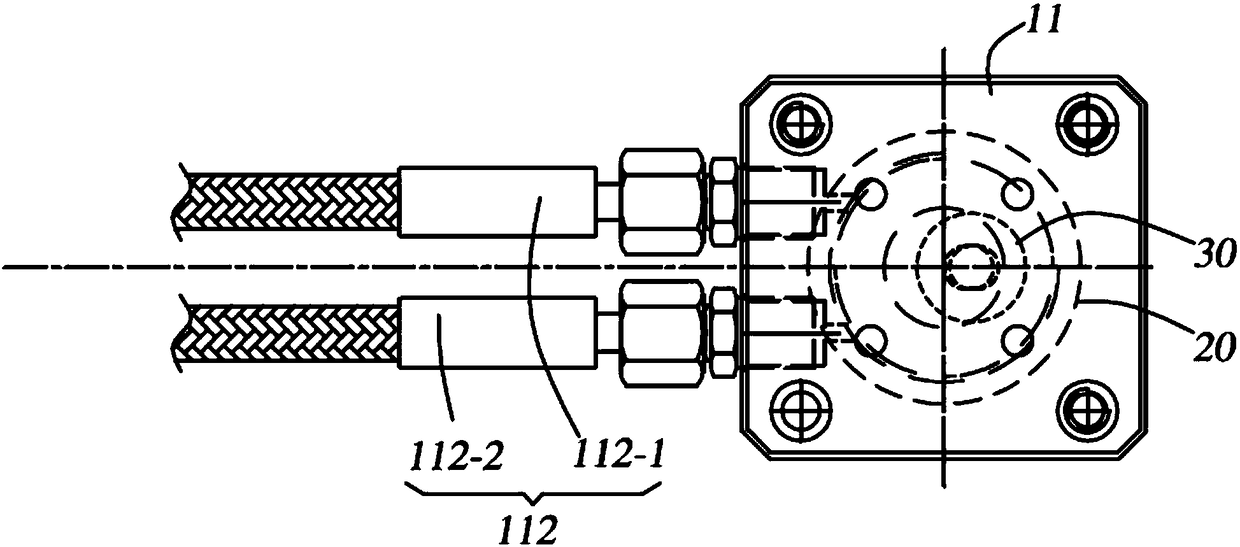

Valve needle drive cylinder and needle valve type hot runner system

A technology of drive cylinder and valve needle, which is applied in the field of hot runner injection molding, can solve the problems of unstable linkage, low strength of pin 40', and difficult processing, so as to improve work stability, reduce production cost, and save process timeliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are all included in the protection scope of the present invention.

[0030] In the various figures of the present invention, some dimensions of structures or parts are exaggerated relative to other structures or parts for convenience of illustration, and thus are only used to illustrate the basic structure of the subject matter of the present invention.

[0031] Terms such as "upper," "over," "lower," "below," and the like, referring to spatially relative positions, are used herein for ease of illustration to describe one element or feature relative to another as shown in the figures The relationship of a unit or feature. The term spatially relative position may be i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com