Small-volume and high-precision temperature measurement module

A temperature measurement module, high-precision technology, applied in thermometers, measuring devices, measuring heat, etc., can solve problems such as limiting the temperature measurement accuracy of thermal resistance measuring instruments, reduce labor costs and time costs, small size, and good consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

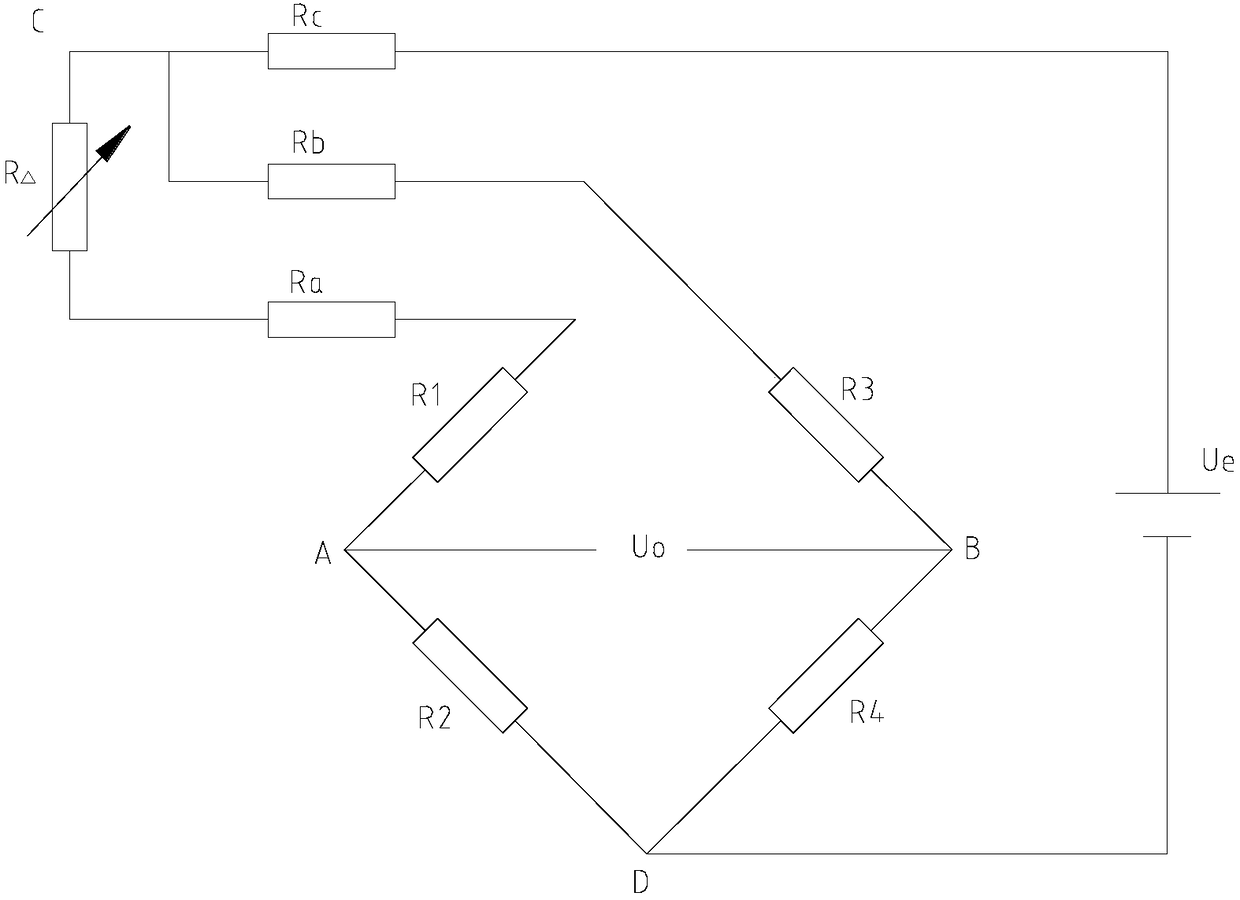

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

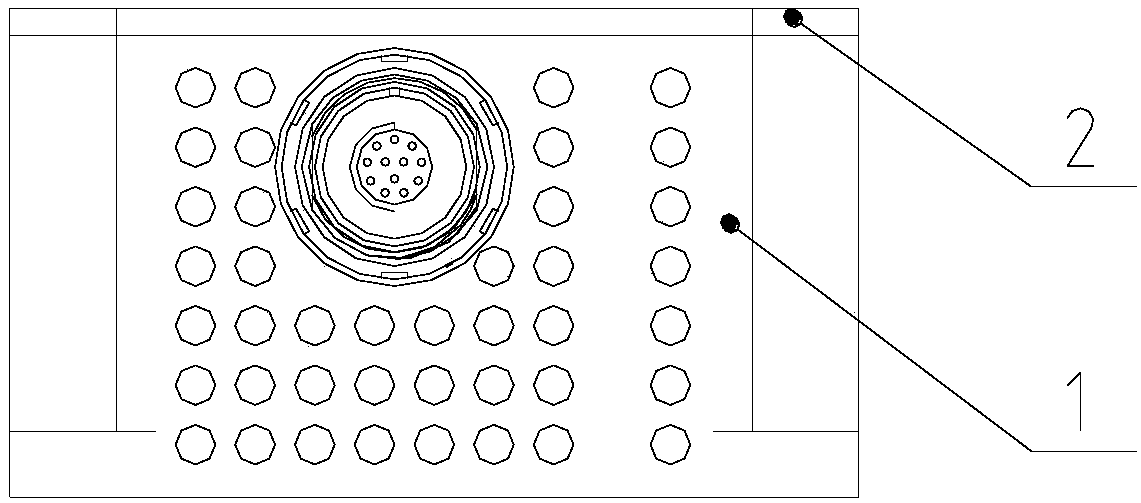

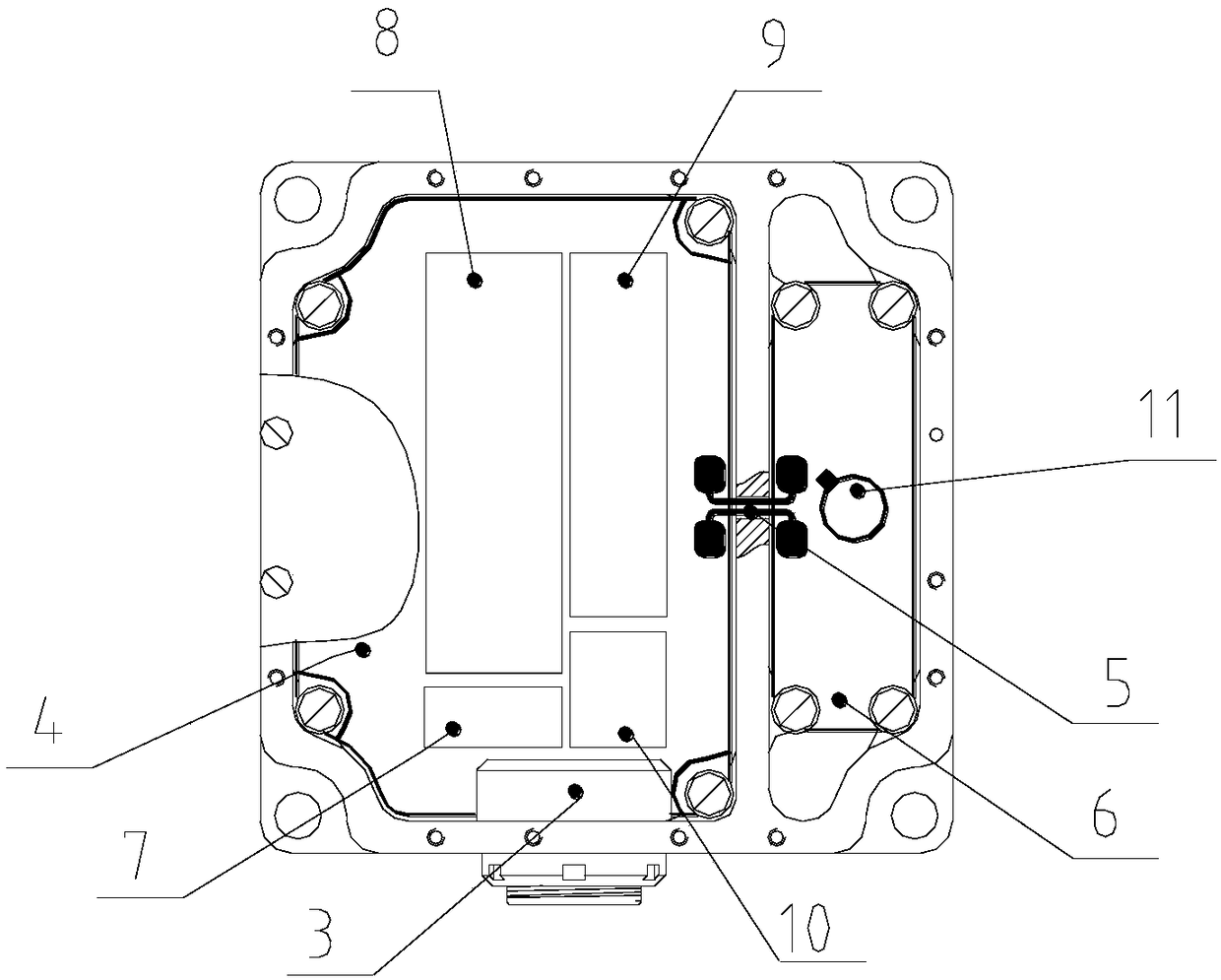

[0024] like figure 2 , image 3 The present invention shown is composed of a cavity 1 , a cover plate 2 , a quick-lock connector 3 , a first printed board assembly 4 , a wall-through cable 5 and a second printed board assembly 6 .

[0025] The first printed board assembly 4 and the second printed board assembly 6 are fixed in different cavities in the cavity 1 by screws, and the first printed board assembly 4 and the second printed board assembly 6 are connected by a through-wall cable 5 Make electrical connections. The first printed board assembly 4 supplies power through the quick-lock connector 3 and provides temperature measurement voltage value output. The quick-lock connector 3 is fixed on the cavity 1 through a lock nut. The cover plate 2 is fixed on the top of the cavity by screws to prevent external extraneous matter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com