Wastewater treatment process system and method for wet desulfurization

A technology for wastewater treatment and wet desulfurization, which is applied in gaseous effluent wastewater treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. Achieving the effect of low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

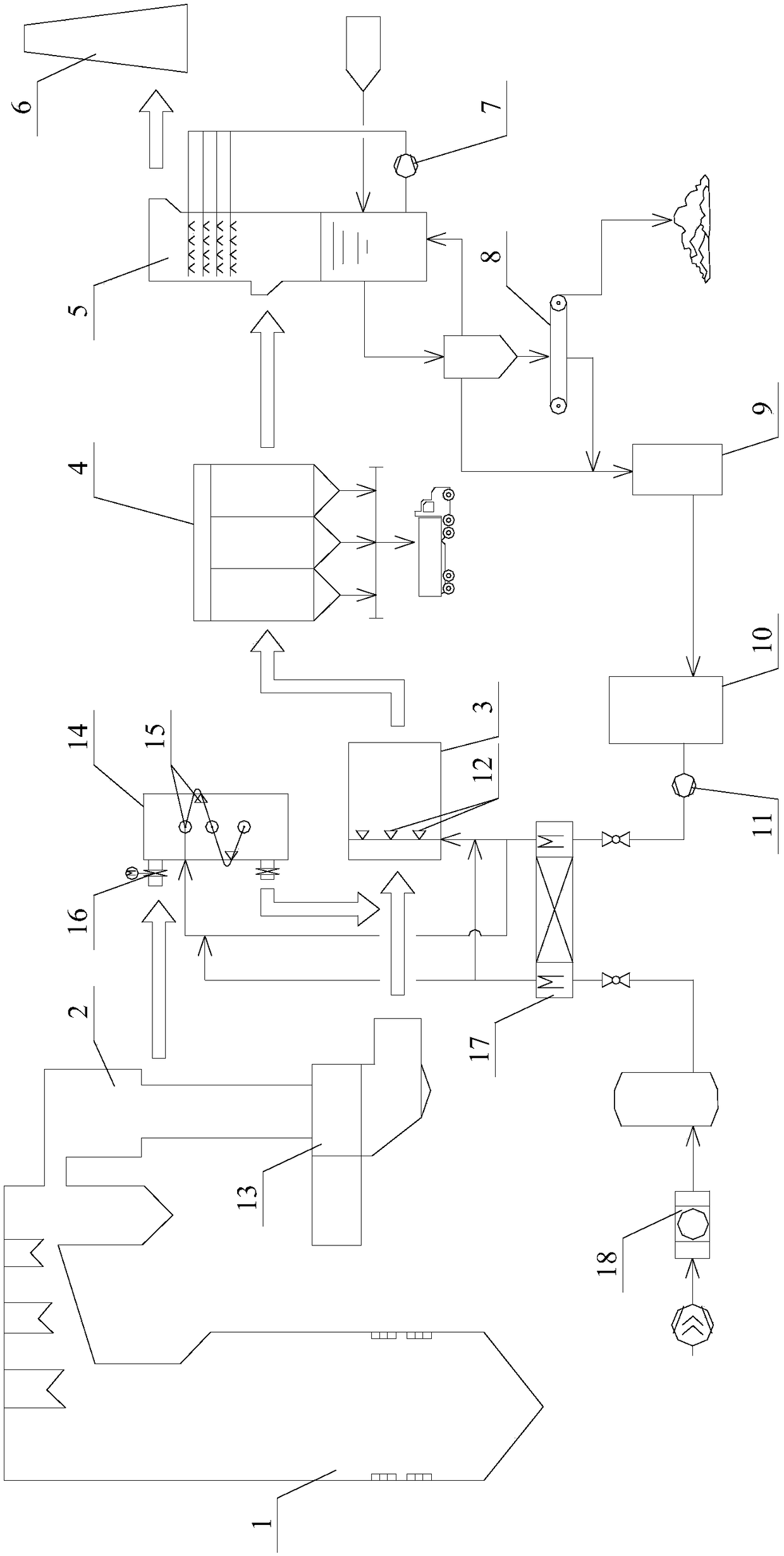

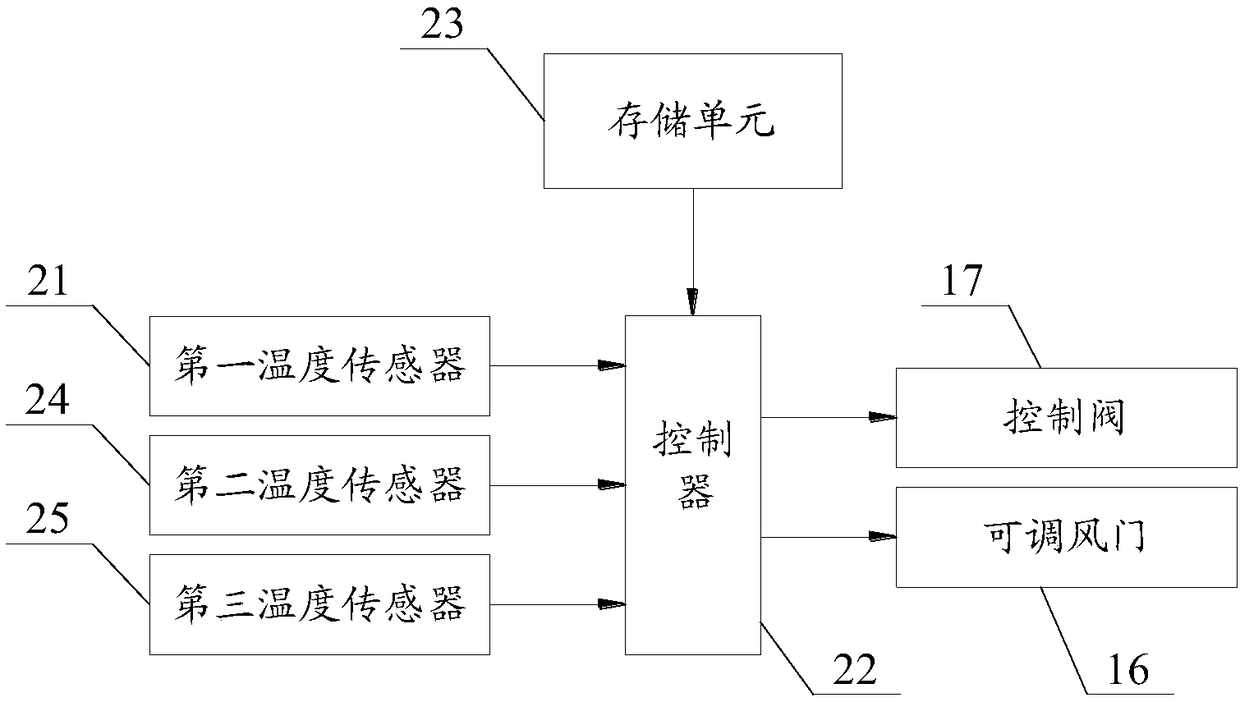

[0033] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] Without loss of generality, this embodiment uses figure 1The flue gas wet desulfurization system shown in is used as the main body of the description, and the wet desulfurization wastewater treatment process system proposed in this application is described in detail. During the working process, the flue gas generated by the combustion of the boiler 1 is treated by the denitrification equipment 2, then the main flue 3 enters the dust collector 4 after passing through the air preheater, enters the wet desulfurization absorption tower 5, and finally passes through the desulfurization flue through the chimney 6 into the atmosphere.

[0035] Among them, the wet desulfurization system establishes desulfurization water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com