Signal detection cable for digital substation and manufacturing technology

A signal detection and substation technology, which is applied in the direction of cable/conductor manufacturing, insulated cables, conductor/cable insulation, etc., can solve the problems of no antibacterial, poor electromagnetic shielding performance, and short service life of the control cable protective layer. Good cushioning effect, good electromagnetic shielding effect, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

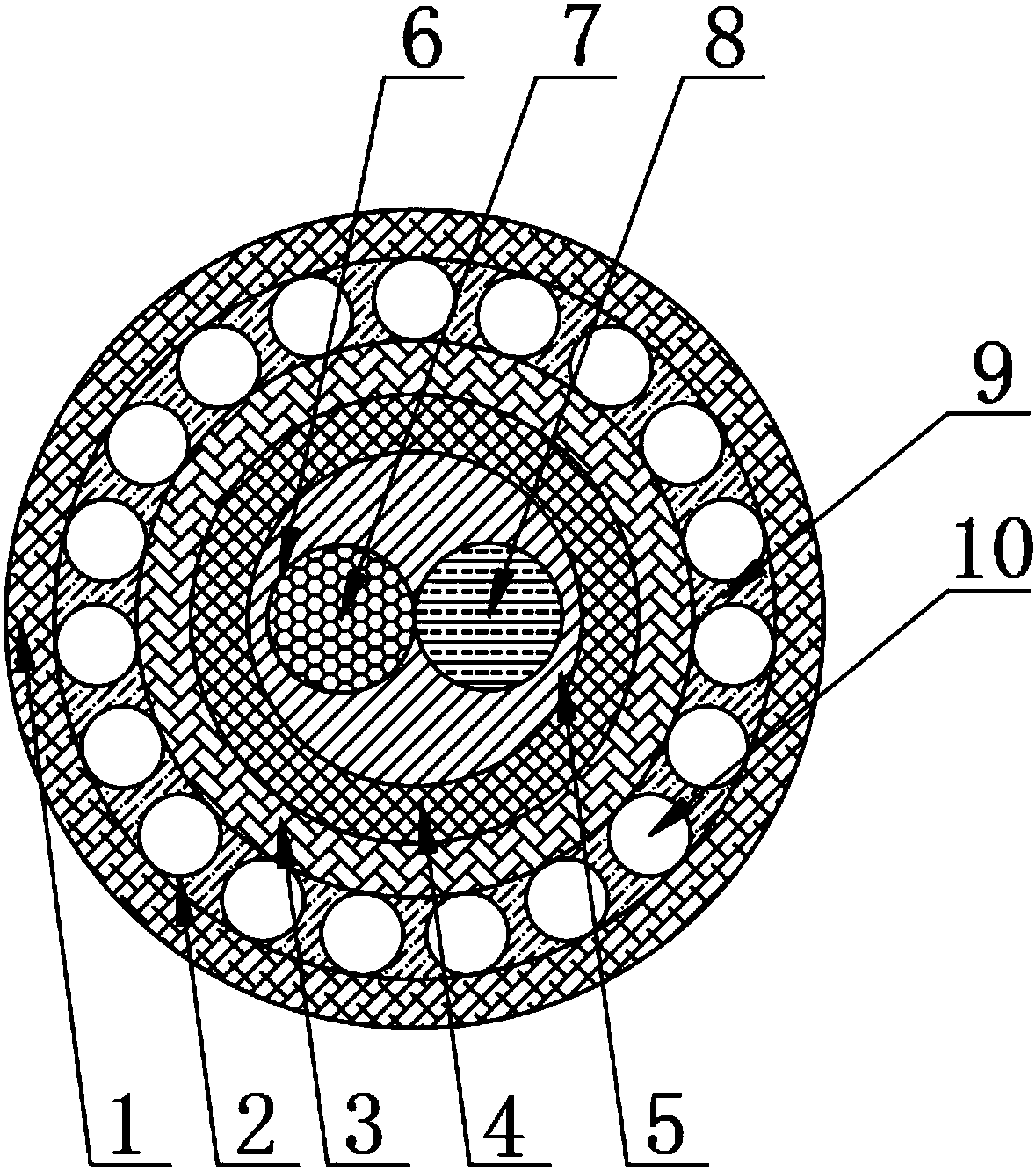

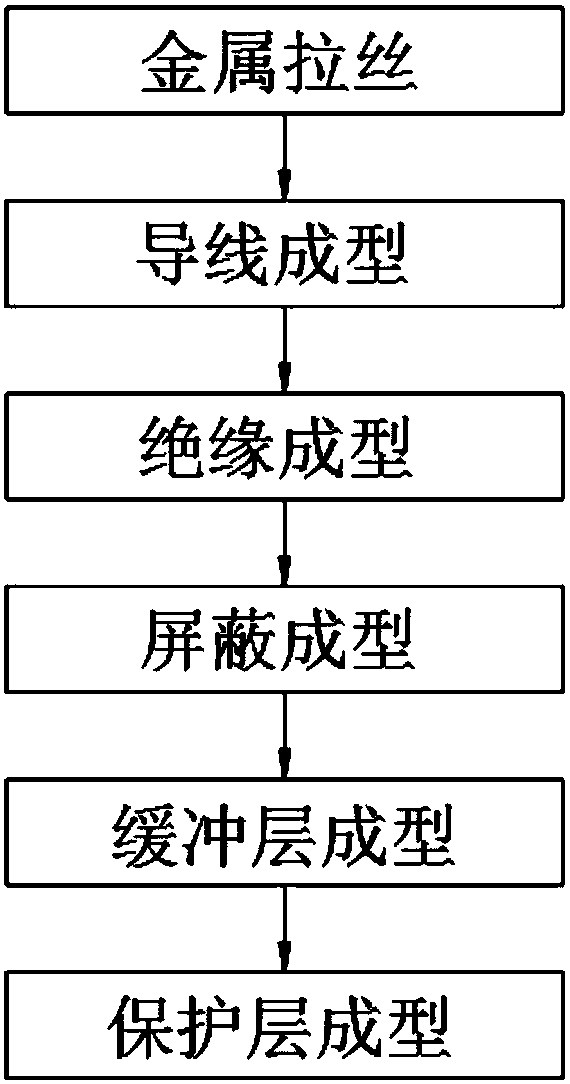

[0023] Example 1: See Figure 1-2 , the present invention provides a signal detection cable for digital substation, comprising a protective layer 1, a buffer layer 2, an armor layer 3, an aluminum foil layer 4, an insulating layer 5 and a conductive core 6, the outer wall of the conductive core 6 is wrapped with an insulating layer 5, The outer wall of the insulating layer 5 is wrapped with an aluminum foil layer 4, the outer wall of the aluminum foil layer 4 is wrapped with an armor layer 3, the outer wall of the armor layer 3 includes a buffer layer 2, the outer wall of the buffer layer 2 is wrapped with a protective layer 1, and the buffer layer 2 includes Rubber shock-absorbing layer 9 and buffer holes 10, the rubber shock-absorbing layer 9 is wrapped on the outside of the armor layer 3, a number of buffer holes 10 are evenly opened on the rubber shock-absorbing layer 9, the conductive core 6 includes copper wires 7 and aluminum wires 8 , the copper wire 7 and the aluminum...

Embodiment 2

[0036] Example 2: see Figure 1-2 , the present invention provides a signal detection cable for digital substation, comprising a protective layer 1, a buffer layer 2, an armor layer 3, an aluminum foil layer 4, an insulating layer 5 and a conductive core 6, the outer wall of the conductive core 6 is wrapped with an insulating layer 5, The outer wall of the insulating layer 5 is wrapped with an aluminum foil layer 4, the outer wall of the aluminum foil layer 4 is wrapped with an armor layer 3, the outer wall of the armor layer 3 includes a buffer layer 2, the outer wall of the buffer layer 2 is wrapped with a protective layer 1, and the buffer layer 2 includes Rubber shock-absorbing layer 9 and buffer holes 10, the rubber shock-absorbing layer 9 is wrapped on the outside of the armor layer 3, a number of buffer holes 10 are evenly opened on the rubber shock-absorbing layer 9, the conductive core 6 includes copper wires 7 and aluminum wires 8 , the copper wire 7 and the aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com