Siphon discharge method for metallurgy

A technology of siphoning and metal liquid, applied in the field of metallurgy, can solve the problems of slow liquid discharge process, affecting temperature requirements, slow working efficiency, etc., to achieve the effect of stable liquid flow rate, avoiding cracks and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

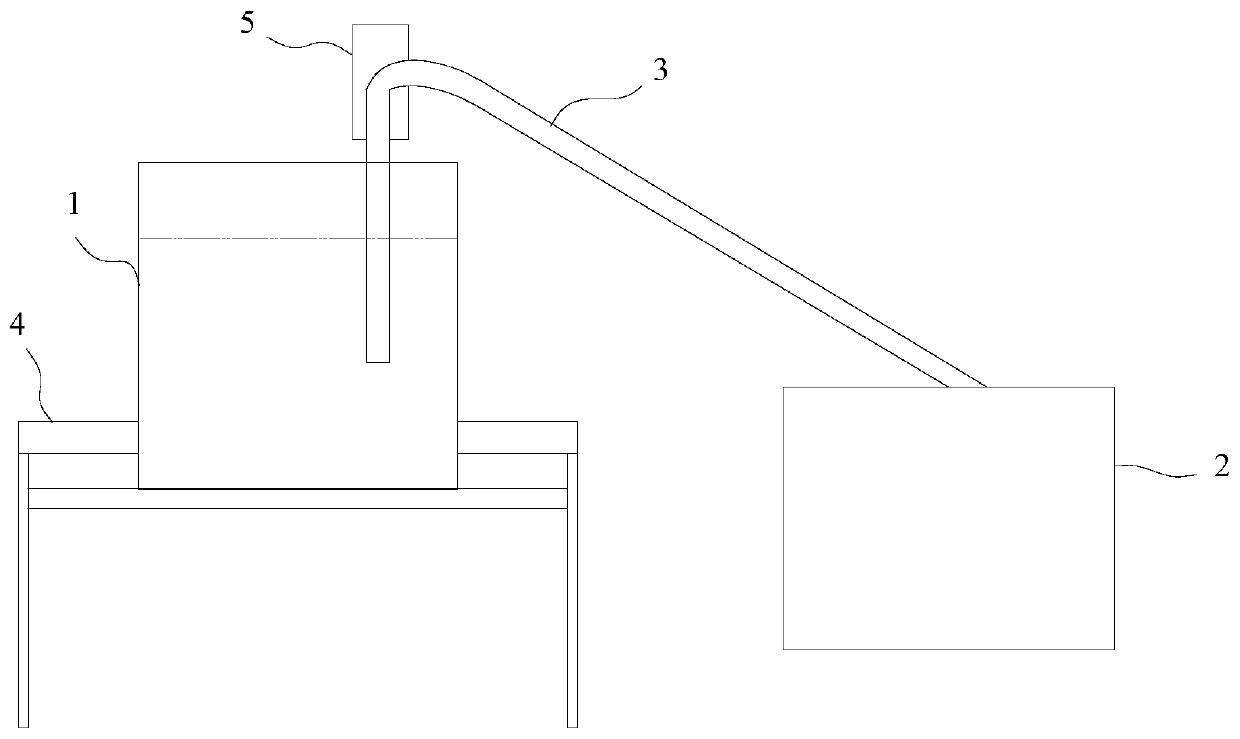

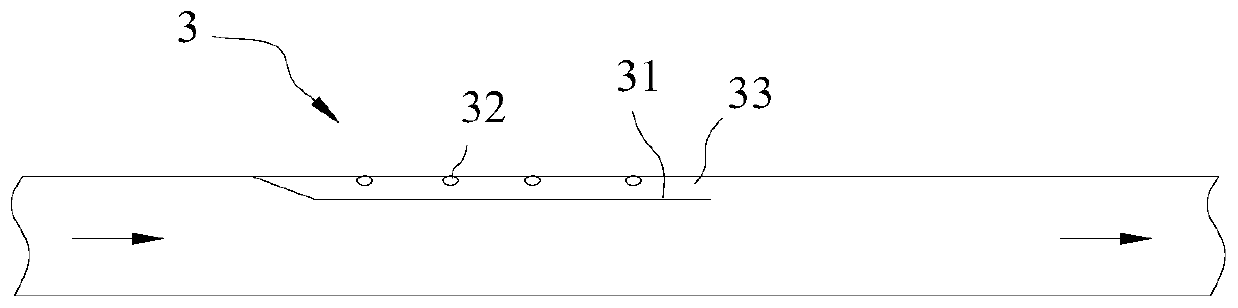

[0022] The method of siphon discharge for metallurgy, such as Figure 1-2 shown, including the following steps:

[0023] One end of the superalloy tube 3 is sealed and slidably inserted into the melting furnace 1, and extended to below the molten metal liquid level of the melting furnace 1, the other end of the superalloy tube 3 is connected to the heat preservation pool 2, and the height of the heat preservation pool 2 is set to be lower than the melting furnace 1 height;

[0024] Use a vacuum pump to vacuumize the superalloy pipe 3 and the heat preservation pool 2 for the first time;

[0025] Preheating the superalloy pipe 3 and the heat preservation pool 2 by means of a heating device;

[0026] The molten metal liquid in the smelting furnace 1 is discharged to the heat preservation pool 2 through the superalloy tube 3 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com