Water-hammer arrestor

A technology of eliminator and water hammer, which is applied in the field of pipe fittings manufacturing, can solve problems such as low work efficiency, paralysis of drainage and water supply systems, and strained valve parts, etc., and achieves easy control and use, good water hammer elimination effect, and simple and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

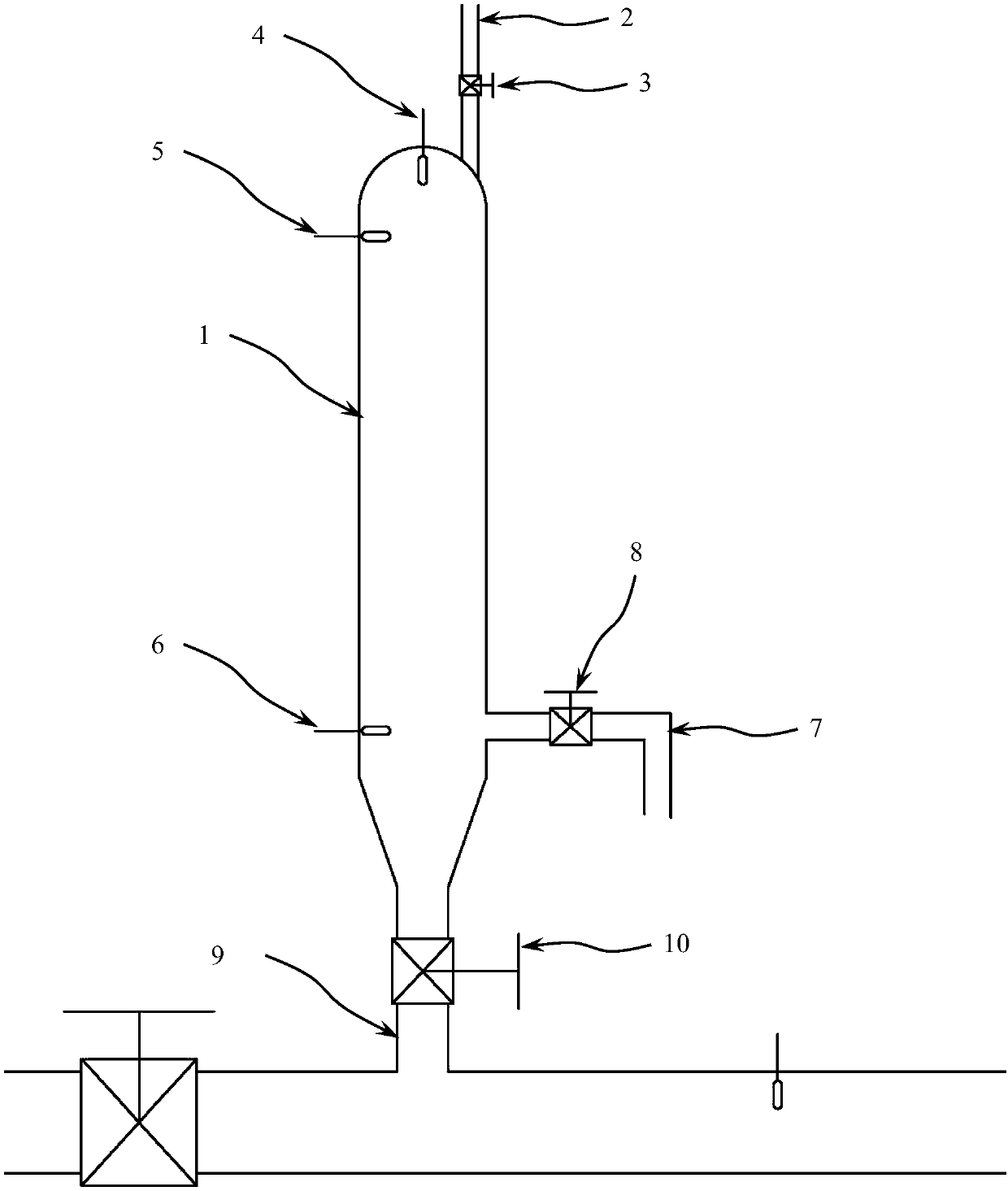

[0049] combine figure 1 As shown, a water hammer eliminator includes a buffer pipe body 1, a compressed air pipeline 2, a pressure sensor 4, a high liquid level sensor 5, a low liquid level sensor 6, a drain pipe 7, and a buffer nozzle 9; The buffer pipe body 1 is a blind pipe with a buffer nozzle 9 at one end, and the closed end of the buffer pipe body 1 is provided with a compressed air pipeline 2 and a pressure sensor 4; the buffer pipe body 1 is provided with a high liquid level sensor 5 near the closed end, and the buffer pipe The body 1 is provided with a low liquid level sensor 6 and a liquid discharge pipe 7 near the end of the buffer nozzle 9 .

[0050]Among them, the compressed air pipeline 2 is provided with a compressed air valve 3; the liquid discharge pipeline 7 is provided with a liquid discharge valve 8; the buffer nozzle 9 is provided with an isolation valve 10. The low liquid level sensor 6 and the discharge pipe 7 are not on the same side, and the distance ...

Embodiment 2

[0053] refer to figure 1 As shown, a water hammer eliminator includes a buffer pipe body 1, a compressed air pipe 2, a pressure sensor 4, a high liquid level sensor 5, a low liquid level sensor 6, a drain pipe 7, a buffer nozzle 9 and a controller; The buffer pipe body 1 is a blind pipe with a buffer nozzle 9 at one end, and the closed end of the buffer pipe body 1 is provided with a compressed air pipeline 2 and a pressure sensor 4; the buffer pipe body 1 is provided with a high liquid level sensor 5 near the closed end, The buffer pipe body 1 is provided with a low liquid level sensor 6 and a liquid discharge pipe 7 at the end close to the buffer pipe mouth 9 .

[0054] Among them, the compressed air pipeline 2 is provided with a compressed air valve 3; the liquid discharge pipeline 7 is provided with a liquid discharge valve 8; the buffer nozzle 9 is provided with an isolation valve 10. The low liquid level sensor 6 and the discharge pipe 7 are not on the same side, and th...

Embodiment 3

[0058] refer to figure 1 Shown, the use of water hammer eliminator, including:

[0059] Close the drain valve 8 and the isolation valve 10, open the compressed air valve 3 and detect the pressure in the buffer pipe body 1, when the pressure in the buffer pipe body 1 is 0.01-0.05MPa lower than the pressure in the fluid pipeline, close the compressed air valve 3, Open the isolation valve 10, and the water hammer arrester starts to work. During water hammer and surge in horizontal pipes, the liquid compresses the volume of the gas inside the bumper rod. The kinetic energy of the liquid is weakened to achieve the purpose of alleviating the water hammer;

[0060] When the liquid level in the buffer tube body 1 reaches the high liquid level sensor 5, close the isolation valve 10, open the liquid discharge valve 8 and the compressed air valve 3, the liquid in the buffer tube body 1 will be discharged through the liquid discharge pipe 7, and the buffer tube body will When the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com