Atomization oil nozzle capable of improving oil injection efficiency

A fuel injector and efficiency technology, which is applied in the field of atomized fuel injectors to improve fuel injection efficiency, can solve the problems of increasing the manufacturing requirements and precision of the precise coupling parts of the fuel injector, and increasing the processing and manufacturing cost of the precise coupling parts of the fuel injector. , to achieve the effect of improving atomization efficiency, improving dispersion efficiency and increasing dispersion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

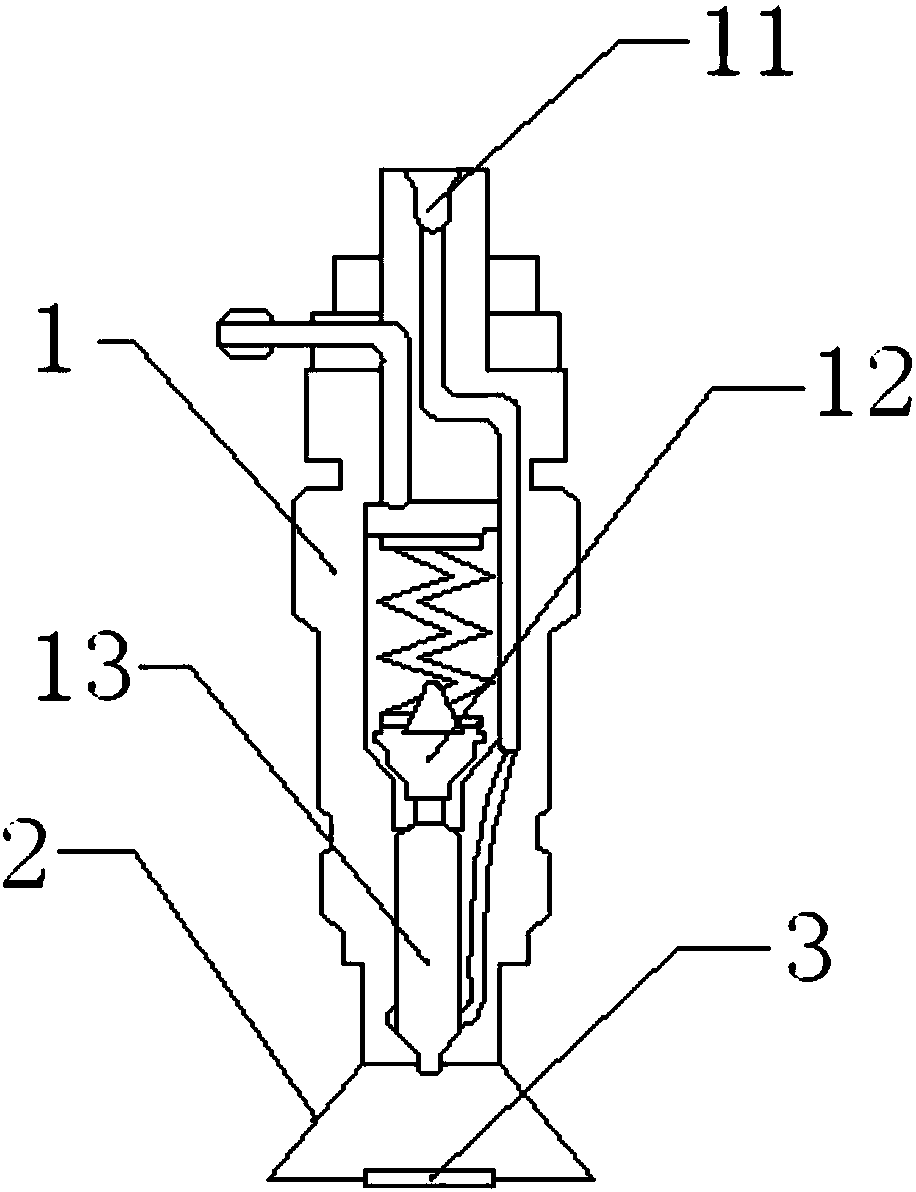

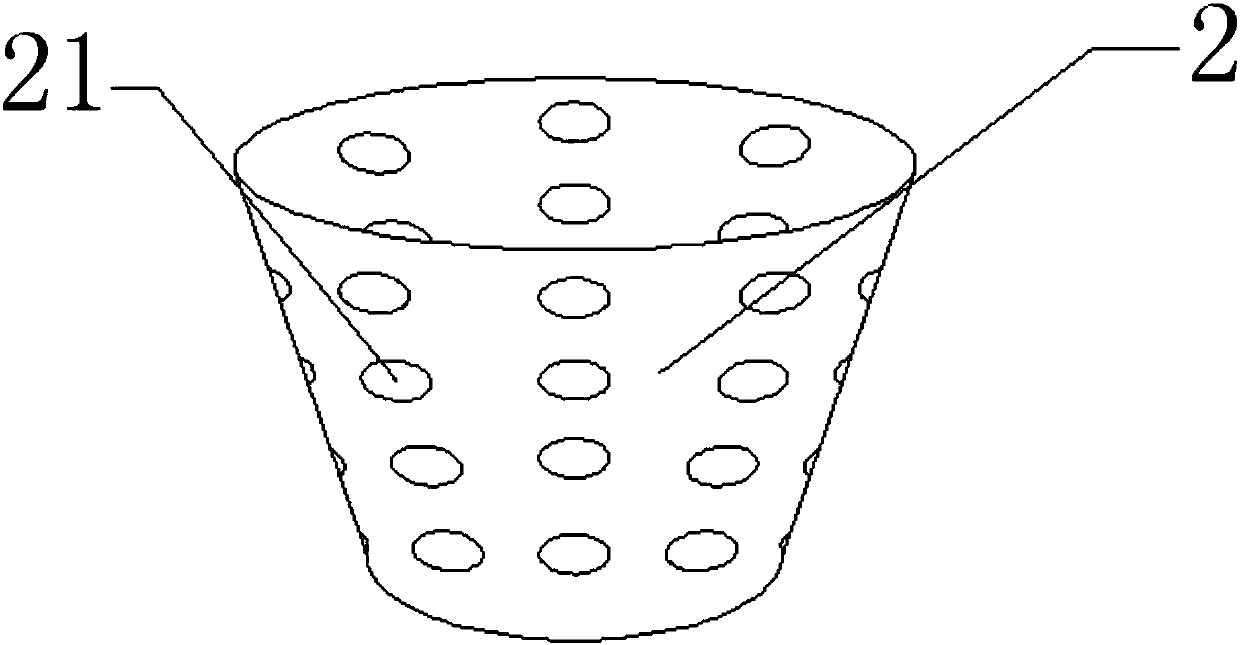

[0019] Such as Figure 1~2 As shown, the present invention is an atomized fuel injector for improving fuel injection efficiency, including a filter screen 11, an electromagnetic control valve 12, and a needle valve 13 arranged inside the fuel injector 1. On the oil outlet, the electromagnetic control valve 12 is arranged under the oil outlet, and the needle valve 13 is arranged under the electromagnetic control valve 12. It is characterized in that a spreading cover 2 is arranged on the lower end surface of the fuel injection nozzle 1, and a spreading cover 2 is installed on the spreading cover 2. The atomizing fan 3 , after the needle valve 13 sprays the oil, the oil is dispersed by the atomizing fan 3 arranged outside the oil injector 1 , and the spreading range is controlled by the spreading cover 2 . The atomizing fan provided in the device can increase the spreading area or improve the atomizing efficiency through the forward and reverse rotation of the atomizing fan, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com