Artificial leather treating agent, artificial leather and preparation method thereof, as well as vehicle provided with artificial leather

A technology of artificial leather and treatment agent, applied in textiles and papermaking, polycarbonate coatings, coatings, etc., can solve the problems of coating peeling and poor wear resistance, and achieve easy control, simple preparation method, high wear resistance, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

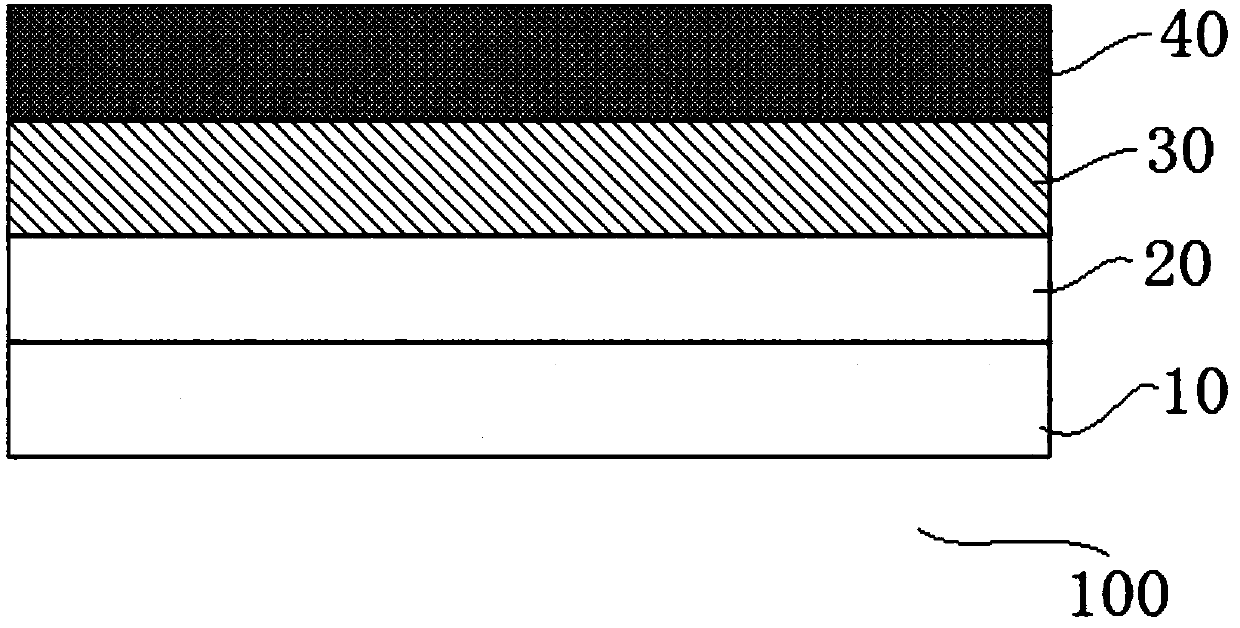

[0074] Such as figure 1 Shown, according to the preparation method of the artificial leather of the embodiment of the third aspect of the present invention, comprises the following steps:

[0075] Step S1, respectively preparing the polyvinyl chloride non-foamed layer mixture and the polyvinyl chloride foamed layer mixture;

[0076] Step S2, placing the prepared polyvinyl chloride foamed layer mixture and polyvinyl chloride non-foamed layer mixture on the backing fabric 10 in sequence, calendering and laminating them to obtain a semi-finished product;

[0077] Step S3, coating the artificial leather treatment agent according to any one of claims 1-3 on the semi-finished product to form a treatment layer 40;

[0078] Step S4 , foaming and embossing the semi-finished product after forming the treatment layer 40 to obtain the artificial leather 100 .

[0079] That is to say, in the preparation method of the artificial leather according to the embodiment of the present invention...

Embodiment 1

[0085] Such as figure 1 As shown, first, mix 5 parts by weight of curing agent, 0.1 part by weight of defoamer, 1.5 parts by weight of leveling agent and 2 parts by weight of hand feeling agent, and obtain the auxiliary agent after mixing uniformly. Then, the auxiliary agent of 8.6 parts by weight is mixed with the polycarbonate resin emulsion of 100 parts by weight, and the viscosity is adjusted to 30 seconds through the No. 3 Ford cup bottom hole by using a viscosity modifier to obtain the artificial leather treatment agent.

[0086] Then, mix the polyvinyl chloride resin of 100 parts by weight, the plasticizer of 85 parts by weight, the thermal stabilizer of 5 parts by weight and the colorant of 10 parts by weight, carry out low-speed stirring under the condition of 1500 rev / mins, low-speed stirring After uniformity, high-speed stirring is carried out under the condition of 2600 rpm, and the primary mixture is obtained after high-speed stirring is uniform. Then, banbury th...

Embodiment 2

[0091] Such as figure 1 As shown, first, mix 4 parts by weight of curing agent, 0.15 parts by weight of defoamer, 1 part by weight of leveling agent and 3 parts by weight of hand feeling agent, and obtain the auxiliary agent after mixing uniformly. Then, the auxiliary agent of 9 parts by weight is mixed with the polycarbonate resin emulsion of 90 parts by weight, and the viscosity is adjusted to 35 seconds through the No. 3 Ford cup bottom hole by using a viscosity modifier to obtain the artificial leather treatment agent.

[0092] Then, mix the polyvinyl chloride resin of 110 parts by weight, the plasticizer of 80 parts by weight, the thermal stabilizer of 6 parts by weight and the colorant of 11 parts by weight, carry out low-speed stirring under the condition of 1100 rev / mins, low-speed stirring After uniformity, high-speed stirring is carried out under the condition of 2300 rpm, and the primary mixture is obtained after high-speed stirring is uniform. Then, banbury the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com