Post-treatment process for acidic pectinase with stable enzyme activity

An acid pectinase and post-treatment technology, which is applied in the direction of enzymes, lyases, hydrolases, etc., can solve the problems of seldom reported, high loss ratio of acid pectinase enzyme activity, etc., achieve high production efficiency, save process cycle, Reduced effect of plate and frame filtration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

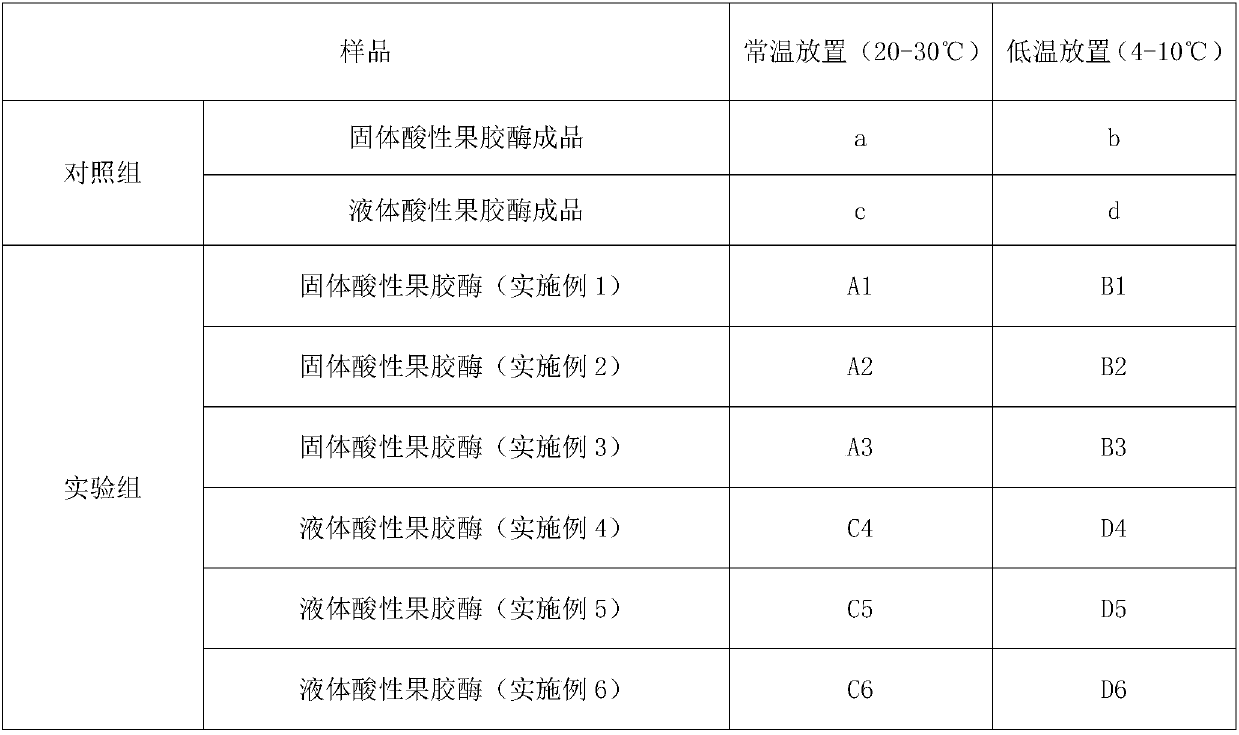

Image

Examples

Embodiment 1

[0028] The post-treatment process of acid pectinase with stable enzyme activity adopts the following operation steps:

[0029] 1) Pretreatment feed liquid

[0030] According to the mass ratio of 7:1, in a 100L stainless steel mixing tank, slowly add distilled water and solid acid pectinase crude product powder successively, while adding, stir evenly until the powder is completely immersed in distilled water, and continue stirring for 30 minutes to obtain a mixed solution A ,spare;

[0031] 2) Adjust the pH value of the mixed solution A to 4.0±0.05

[0032] Add the citric acid solution of 2mol / L to the mixed solution A of step 1) in a small amount several times, slowly adjust the pH value of mixed solution A, after adding the citric acid solution of 2mol / L at every turn, take a sample and measure its pH with a pH meter value, to ensure that the pH value changes at a rate of 0.1±0.05 each time, until the pH value of the mixed solution A is stable at 4.0±0.05, and stir for 30 m...

Embodiment 2

[0040] The post-treatment process of acid pectinase with stable enzyme activity adopts the following operation steps:

[0041] 1) Pretreatment feed liquid

[0042] According to the mass ratio of 6:1, in a 100L stainless steel mixing tank, slowly add distilled water and powder of solid acid pectinase crude product in turn, while adding, stir evenly until the powder is completely immersed in distilled water, and continue stirring for 20 minutes to obtain a mixed solution A ,spare;

[0043] 2) Adjust the pH value of the mixed solution A to 3.5±0.05

[0044] Add the citric acid solution of 2mol / L to the mixed solution A of step 1) in a small amount several times, slowly adjust the pH value of mixed solution A, after adding the citric acid solution of 2mol / L at every turn, take a sample and measure its pH with a pH meter value, to ensure that the pH value varies by 0.1 ± 0.05 each time, until the pH value of the mixed solution A is stable at 3.5 ± 0.05, stir for 20 minutes to obtai...

Embodiment 3

[0052] The post-treatment process of acid pectinase with stable enzyme activity adopts the following operation steps:

[0053] 1) Pretreatment feed liquid

[0054] According to the mass ratio of 8:1, in a 100L stainless steel mixing tank, slowly add distilled water and solid acid pectinase crude product powder sequentially, while adding, stir evenly until the powder is completely immersed in distilled water, and continue stirring for 40 minutes to obtain a mixed solution A ,spare;

[0055] 2) Adjust the pH value of the mixed solution A to 4.5±0.05

[0056] Add the citric acid solution of 2mol / L to the mixed solution A of step 1) in a small amount several times, slowly adjust the pH value of mixed solution A, after adding the citric acid solution of 2mol / L at every turn, take a sample and measure its pH with a pH meter value, to ensure that the pH value varies by 0.1±0.05 each time, until the pH value of the mixed solution A is stable at 4.5±0.05, and stir for 40 minutes to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com