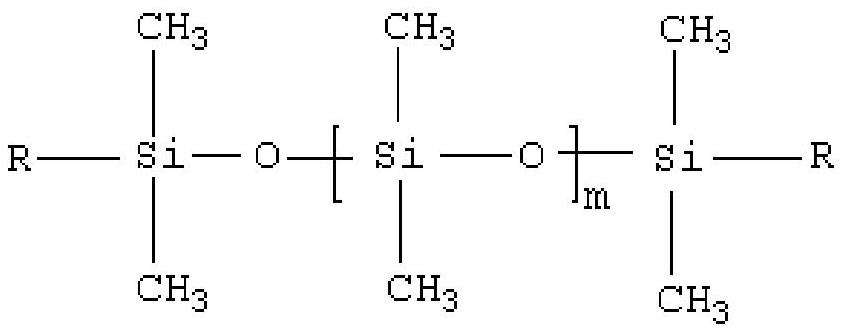

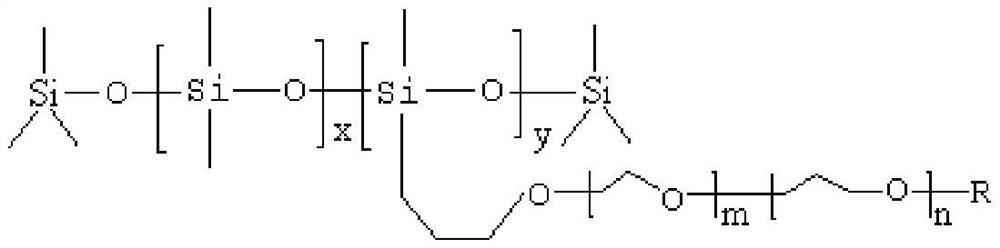

A kind of ultra-high molecular weight polyether modified polysiloxane for leveling agent and its preparation method and application

An ultra-high molecular weight, polyether modified technology, applied in applications, household utensils, inks, etc., can solve the problems of leveling, anti-scratch performance and gloss, reduce leveling, difficult to synthesize, etc., to achieve excellent Leveling and anti-scratch performance, reduced steric effect, high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A preparation method of ultra-high molecular weight polyether modified polysiloxane, comprising steps:

[0055] (1) Allyl polyether (the molar ratio of ring ethoxy and cyclopropoxy is 1:1, the molecular weight is 500g / mol, hydroxyl end-blocking, available from Hangzhou Danwei Technology Co., Ltd.) and toluene into a three-necked flask And add a condensing reflux device, add a tetrahydrofuran solution of chloroplatinic acid with a mass concentration of 2%, and heat up to 80°C, which is conducive to the rapid completion of the hydrosilylation reaction at a higher temperature, and slowly add methyldichlorosilane dropwise to allow Methyldichlorosilane fully reacted to reduce losses, and the dropwise addition time was 1 hour. React at 90°C for 6 hours; then distill under reduced pressure at 110°C for 1 hour to obtain silicon ether; among them, the mass of toluene is 30% of the total mass of allyl polyether and methyl dichlorosilane; The molar ratio of propyl polyether is 1....

Embodiment 2

[0061] A preparation method of ultra-high molecular weight polyether modified polysiloxane, comprising steps:

[0062] (1) Allyl polyether (the molar ratio of ring ethoxy group and cyclopropoxy group in the raw material is 3:1, the molecular weight is 1000g / mol, hydroxyl end-capping, Zhejiang Huangma Technology Co., Ltd. DEM-1002) and toluene are added to the three-necked flask And add a condensing reflux device, add a tetrahydrofuran solution of chloroplatinic acid with a mass concentration of 2%, heat up to 82°C, slowly add methyldichlorosilane dropwise, the dropwise addition time is 1 hour, and react at 100°C for 6 hours; then Distill under reduced pressure at 110°C for 1 hour to obtain silicon ether; among them, the mass of toluene is 35% of the total mass of allyl polyether and methyl dichlorosilane; the molar ratio of methyl dichlorosilane to allyl polyether is 1.2 : 1; In terms of pure substance, the quality of chloroplatinic acid used is 0.0025% of the total mass of al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com