Modified polyurethane material and preparation method thereof

A polyurethane material and modification technology, which is applied in the field of polymer materials, can solve problems such as high crystallinity and high bulk viscosity, and achieve the effects of convenient and practical operation, cheap and easy-to-obtain raw materials, and good practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The embodiment of the present invention provides a kind of preparation method of modified polyurethane material, it comprises:

[0016] S1. Mix the chain transfer agent with the cyclic ester monomer, and undergo a ring-opening polymerization reaction under the catalysis of an organometallic catalyst to obtain a star polyester compound. Wherein, the chain transfer agent is vegetable oil or its derivatives whose side chains contain hydroxyl groups.

[0017] Macromolecules with topological structures such as dendritic, comb-shaped, hyperbranched, star-shaped, and H-shaped branched chain structures and ring-shaped topological polymers are of great significance in the fields of material modification, nanotechnology and biomedicine. New functional polymers with important application prospects have been paid more and more attention by people. The embodiment of the present invention uses "Immortal" ring-opening polymerization of cyclic ester monomers to synthesize star-shaped ...

Embodiment 1

[0051] This embodiment provides a kind of modified polyurethane material, and its preparation method is as follows:

[0052] S1. Under anhydrous and oxygen-free conditions, the chain transfer agent (castor oil) and the organometallic catalyst are sequentially added in proportion to the toluene solution of the cyclic ester monomer (L-lactide monomer) (2mol / L ), its feed ratio is: organometallic catalyst 1: chain transfer agent: cyclic ester monomer=1:1:100, M n theo ≈15,300, react at a temperature of 60°C for 10 hours to obtain a star-shaped polyester compound, the product is not separated and is used for future use.

[0053] S2. Heat polytetrahydrofuran (PTMG-2000) to 120° C., and vacuum dehydrate for 3 hours.

[0054] S2. Cool down the dehydrated PTMG-2000 to 85° C., add isophorone diisocyanate, and stir for 3.5 hours to obtain a polyurethane prepolymer.

[0055] S3. Add the above-mentioned star polyester compound and small molecule chain extender (BDO) to the polyurethane...

Embodiment 2~30

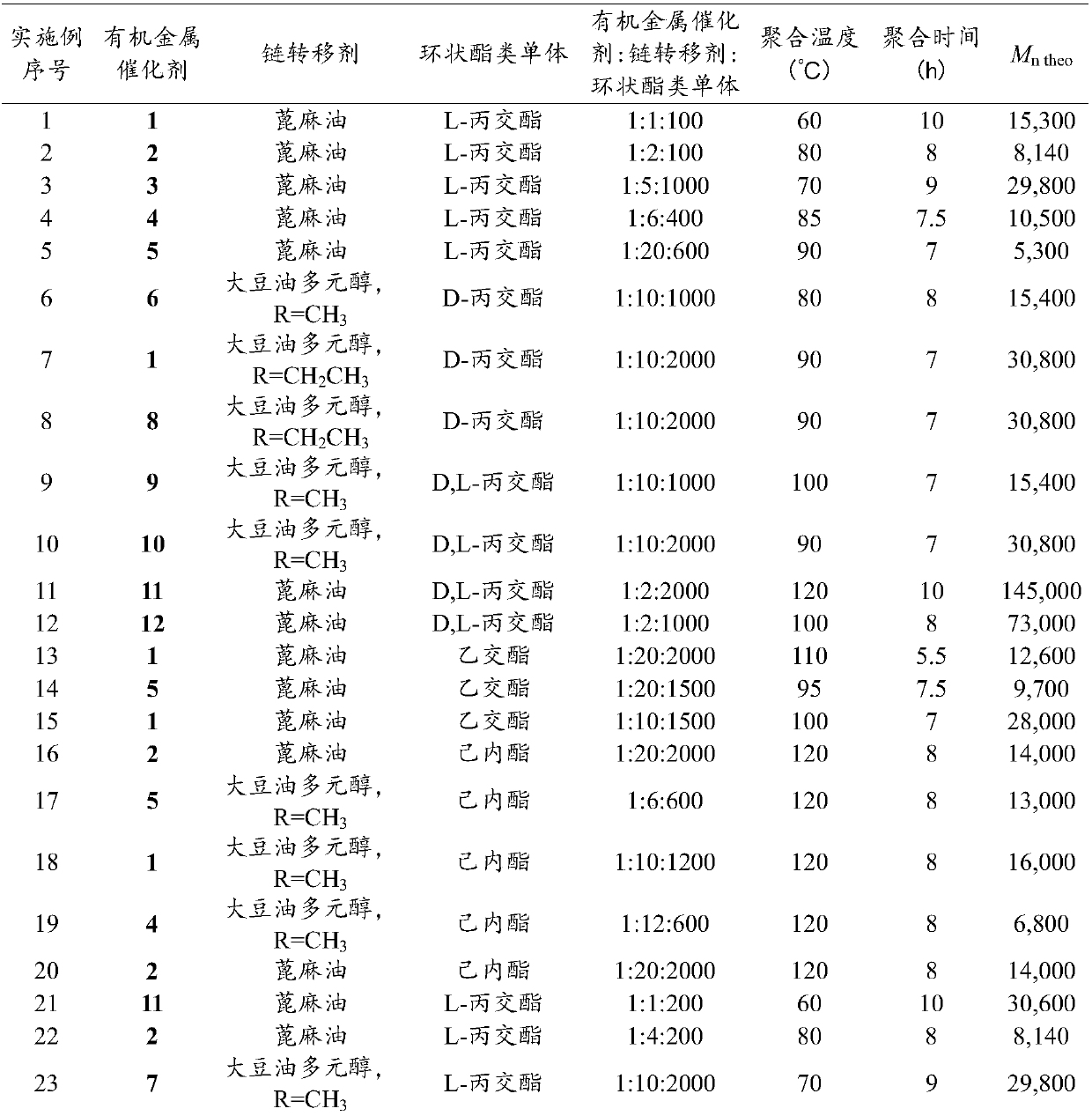

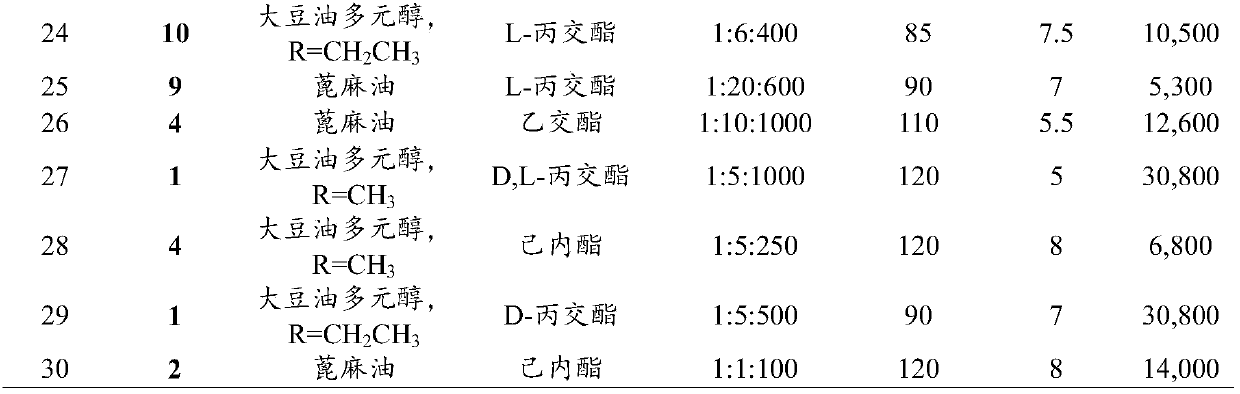

[0058] Embodiments 2-30 respectively provide a modified polyurethane material, the preparation method of which is basically similar to that of embodiment 1, and the difference from embodiment 1 lies in the type and amount of raw materials, reaction temperature, time and so on. The specific preparation method can be carried out with reference to Example 1. The reaction parameters of the synthetic star polyester compound stage are shown in Table 1, and the reaction parameters of the synthetic modified polyurethane material stage are shown in Table 2, and are obtained according to the national standard GBT13022-1991 The performance of the modified polyurethane material was tested under the test conditions: 20°C, the moving speed of the gripper was 50mm / min, and the test results are shown in Table 3.

[0059] Table 1. Experimental parameters for the preparation of star-shaped polyester compounds

[0060]

[0061]

[0062] Table 2. Reaction parameters for preparing modified p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com