Deep sea ore conveying system storage bin with material guiding device

A material guiding device and conveying system technology, which is applied in the mining of minerals, special mining, loading/unloading, etc., can solve the problems of material accumulation and blocked nozzles, and achieve the effect of convenient maintenance, simple structure and improved mining efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

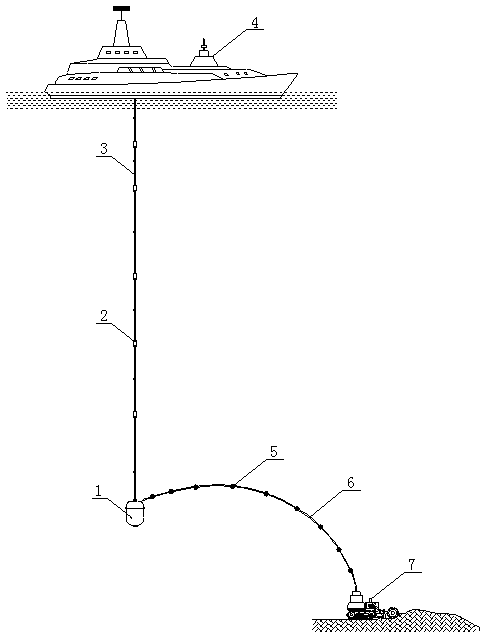

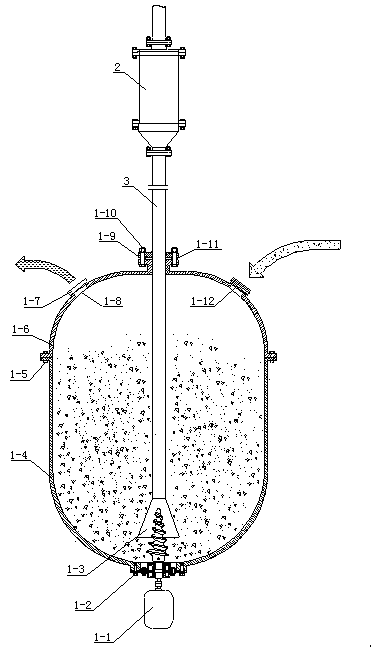

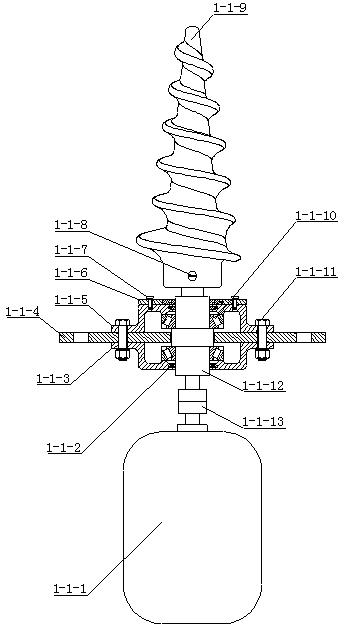

[0016] Such as Figure 1 to Figure 3 As shown, a deep-sea ore conveying system storage bin with a material guide device is mainly composed of a material guide device 1-1, a material guide device connecting bolt 1-2, an upper bin body 1-6, and a bin body connecting bolt assembly 1 -5, lower bin body 1-4, ore filter cover 1-7, connecting flange 1-9, flange connecting bolt assembly 1-10 and adjusting gasket 1-11, suitable for deep sea ore transportation The system is mainly composed of slurry conveying hose 6, buoyancy ball 5, slurry pump 2, lifting hard pipe 3, sea surface mining ship 4, storage bin 1 and ore collector 7, etc. The lifting hard pipe 3 is laid upward from the storage bin 1 To the surface mining ship 4.

[0017] as attached figure 2 As shown in the storage bin of the deep-sea ore conveying system with a guide device, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com