Dendritic polymer modified magnetic microspheres with uniform particle size and its preparation method and application

A dendritic and macromolecular technology, applied in the field of magnetic microspheres and their preparation, can solve the problems of uneven particle size, time-consuming, and many steps, and achieves good dispersibility and stability, great application prospects, and uniform particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

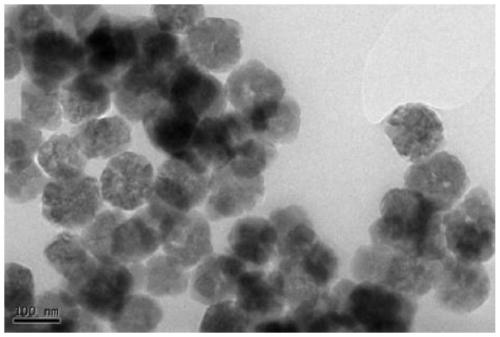

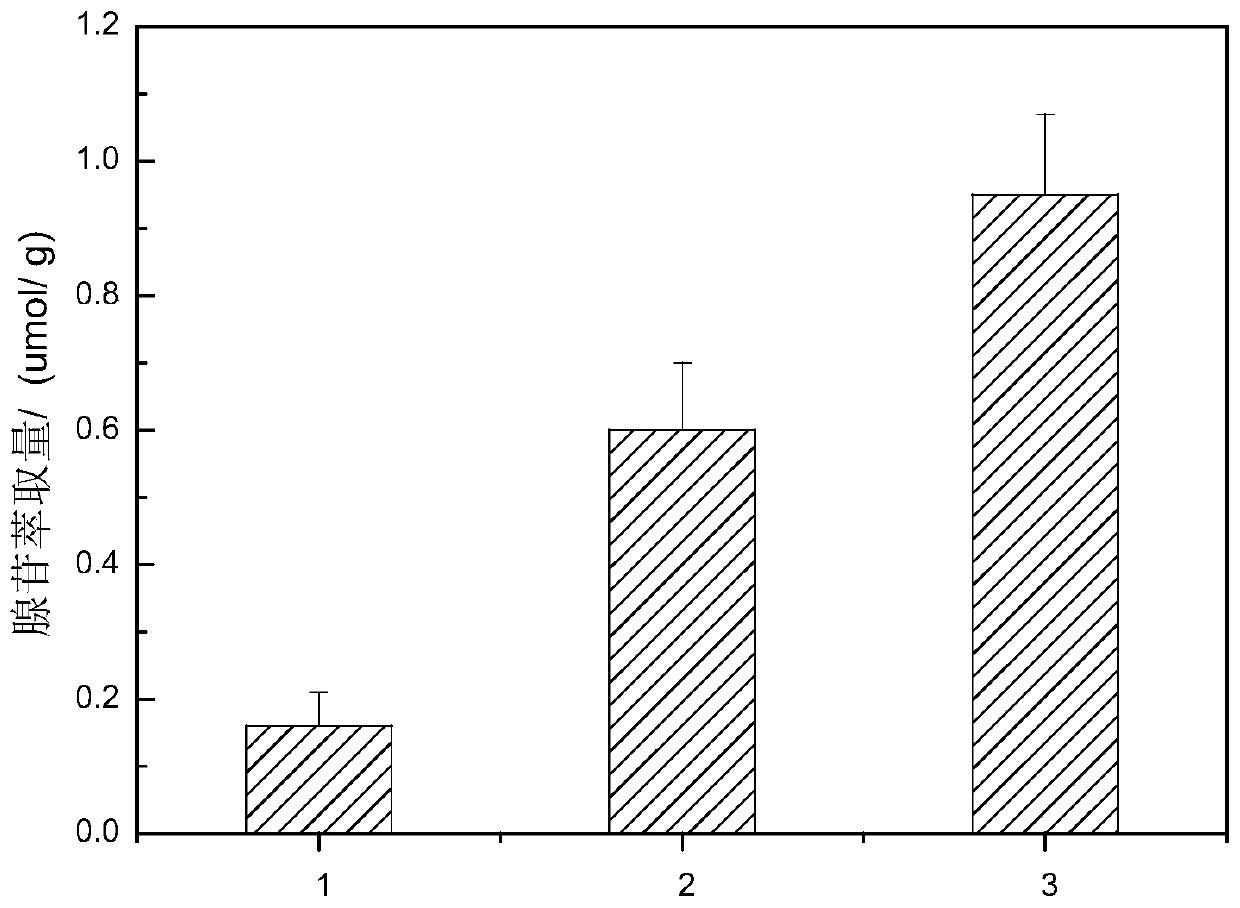

[0035] The present invention also provides a method for preparing dendritic polymer modified magnetic microspheres with uniform particle size. The method includes the following steps: S100, preparing a solution for synthesizing magnetic microspheres; S200, uniformly dispersing the dendrimer In the solution for synthesizing magnetic microspheres; S300, the mixed solution obtained in step S200 is synthesized by a hydrothermal synthesis one-pot method to dendrimer-modified magnetic microspheres. Such as figure 1 TEM image of the fourth-generation PAMAM dendrimer modified magnetic ferroferric oxide microspheres; image 3 The fourth-generation PAMAM dendrimer modified magnetic ferroferric oxide microspheres modified boric acid for adenosine extraction ( image 3 Middle 3), and the background literature Chem. Eur. J. 2006, 12, 6341. The amount of adenosine extracted by the amino functionalized magnetic microspheres prepared in the literature after modified with boric acid ( image 3 In...

Embodiment 1

[0043] Example 1: Magnetic microspheres of ferroferric oxide were obtained according to the following preparation method:

[0044] 1.0 parts by weight of ferric chloride hexahydrate, 2.0 parts by weight of anhydrous sodium acetate, 1 part by weight of fourth-generation PAMAM dendrimer, dissolved in 35.0 parts by weight of ethylene glycol solution, mixed uniformly, and transferred to hydrothermal The reaction kettle has a hydrothermal reaction temperature of 200°C. The reaction time is 6 hours. The prepared magnetic microspheres are washed 3-5 times with methanol, 3-5 times with ethanol, 3-5 times with water, and 3-5 times with ethanol. Vacuum drying at 50°C for 12 hours for later use.

[0045] Such as figure 1 As shown, figure 1 It is a transmission electron micrograph of the fourth-generation PAMAM dendrimer modified magnetic ferroferric oxide microspheres. It can be seen from the figure that its particle size is uniform, about 100nm.

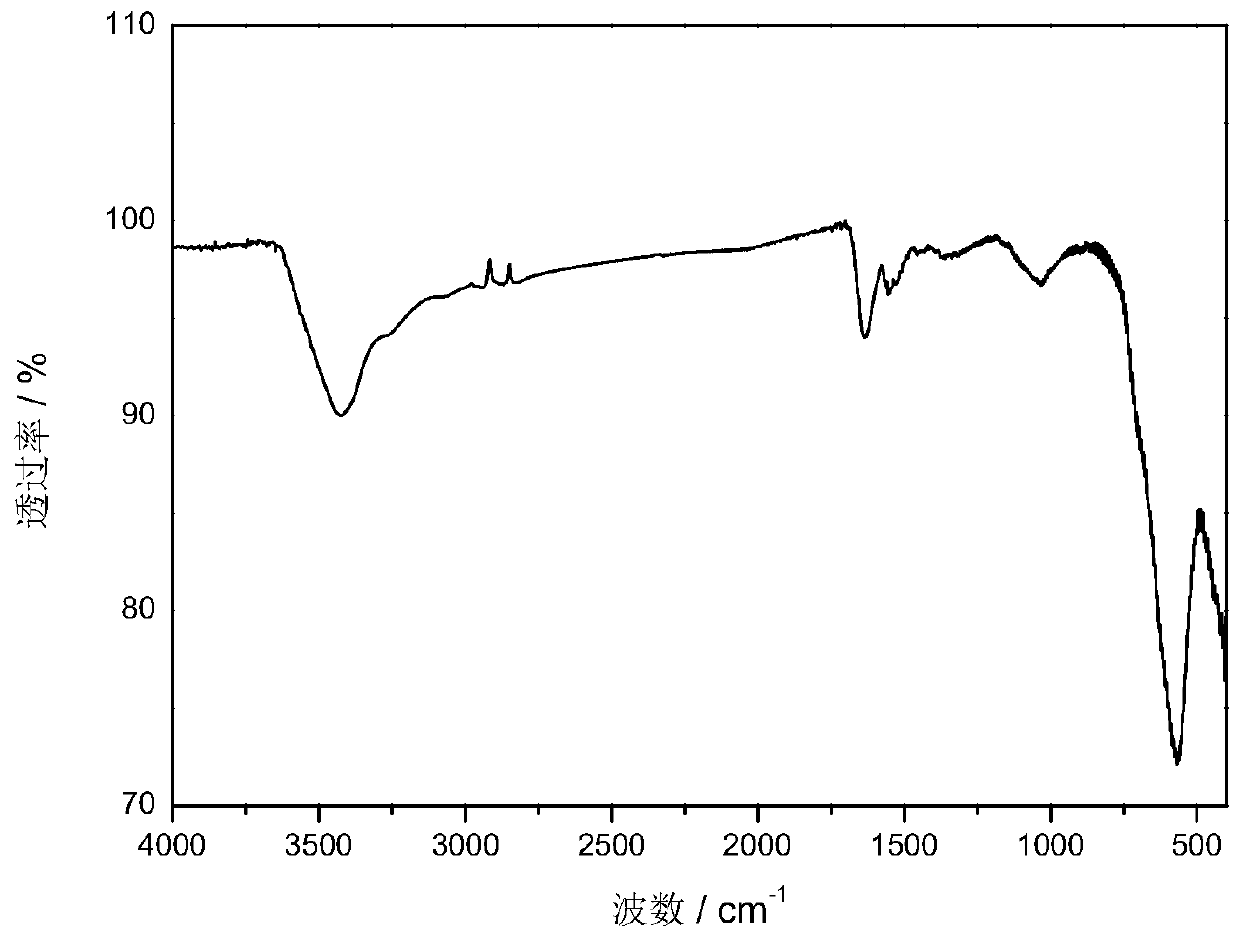

[0046] figure 2 Infrared image of the four...

Embodiment 2

[0047] Example 2: Preparation of cobalt oxide magnetic microspheres:

[0048] 2.0 parts by weight of cobalt chloride hexahydrate, 10 parts by weight of anhydrous sodium acetate, 2 parts by weight of dendrimer, dissolved in 45 parts by weight of ethylene glycol solution, mixed uniformly, transferred to the hydrothermal reactor, hydrothermally The reaction temperature is 300°C. The reaction time is 8 hours. The prepared magnetic microspheres are washed 3-5 times with methanol, 3-5 times with ethanol, 3-5 times with water, and 3-5 times with ethanol. Vacuum drying at 50°C for 12 hours for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com