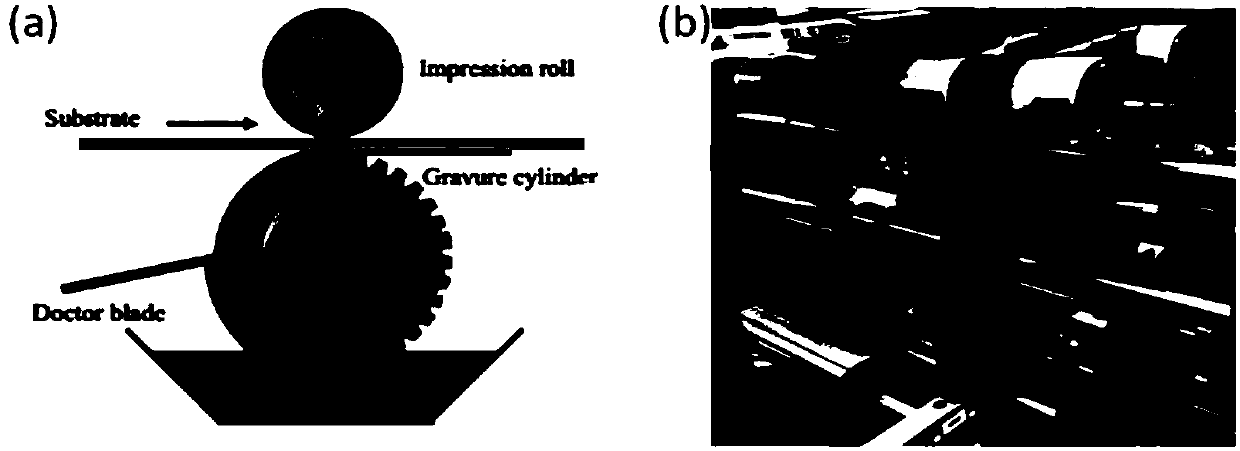

Method for preparing electrode of supercapacitor based on reel-to-reel printing technique

A technology of supercapacitor and printing technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The method for preparing electrode in the present embodiment comprises the following steps:

[0017] (1) Use isopropanol, ethanol, deionized water to ultrasonically clean the foamed nickel substrate for 30 minutes, and dry it for later use; respectively take a certain amount of activated carbon and place it in a 90-degree oven to dry for 1 hour and polyvinylidene fluoride ( PVDF) placed in an oven at 80 degrees and dried for 6 hours before use;

[0018] (2) Dissolve the dried PVDF in N-methylpyrrolidone (NMP), prepare a 2% PVDF solution, and stir at room temperature for 10 hours;

[0019] (3) Get 18g activated carbon and 2g PVDF solution and mix, after stirring for 2 hours, then add 2% silver nanowires, stir for 30 minutes and then prepare printing paste;

[0020] (4) Apply roll-to-roll micro-gravure printing to the above-mentioned prepared slurry on the aluminum foil, the base width of the aluminum foil is 15cm, the coating speed is set to 0.2m / min, and the coating sp...

Embodiment 2

[0025] The method for preparing electrode in the present embodiment comprises the following steps:

[0026] (1) Use isopropanol, ethanol, and deionized water to ultrasonically clean the nickel foam substrate for 30 minutes, and dry it before use; take a certain amount of activated carbon and dry it in an oven at 90 degrees for 1 hour and PVDF at 80 degrees Dry in the oven for 6 hours before use;

[0027] (2) Dissolve the dried PVDF in NMP, prepare a 2% PVDF solution, and stir at room temperature for 10 hours;

[0028] (3) Get 12g activated carbon, the mixture of 6g carbon nanotubes and 2g PVDF solution mix, after stirring for 2 hours, then add 4% silver nanowires, stir for 30 minutes and then prepare printing paste;

[0029] (4) Apply the above-mentioned prepared slurry to the aluminum foil by slit coating. The width of the base of the aluminum foil is 15 cm, the speed of the base is 0.3 m / min, the thickness of the gasket is between 2 microns and 10 microns, and the ink is in...

Embodiment 3

[0034] The method for preparing electrode in the present embodiment comprises the following steps:

[0035] (1) Use isopropanol, ethanol, and deionized water to ultrasonically clean the foamed nickel substrate for 30 minutes, and dry it for use; take a certain amount of graphene and place it in a 90-degree oven for 1 hour and PVDF in a 80-degree oven. Dry in an oven for 6 hours before use;

[0036] (2) Dissolve the dried PVDF in NMP, prepare a 2% PVDF solution, and stir at room temperature for 10 hours;

[0037] (3) Get 18g graphene and 2gPVDF solution to mix, after stirring for 2 hours, then add 3% silver nanowires, stir for 30 minutes and then prepare printing paste;

[0038] (4) Apply roll-to-roll micro-gravure printing to the above-mentioned prepared slurry on the aluminum foil, the base width of the aluminum foil is 15cm, the coating speed is set to 0.2m / min, and the coating speed ratio is 90% to 360%, which can form a uniform The thin film electrodes are dried in an 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com