High-strength transparent hydraulic coupling device for PIV testing

A technology of transparent liquid and coupler, which is applied in the direction of transmission, fluid transmission, transmission control, etc., can solve the problems of inconvenient placement of instruments, unclear images, etc., and achieve simple and flexible design, avoid light scattering, and facilitate observed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

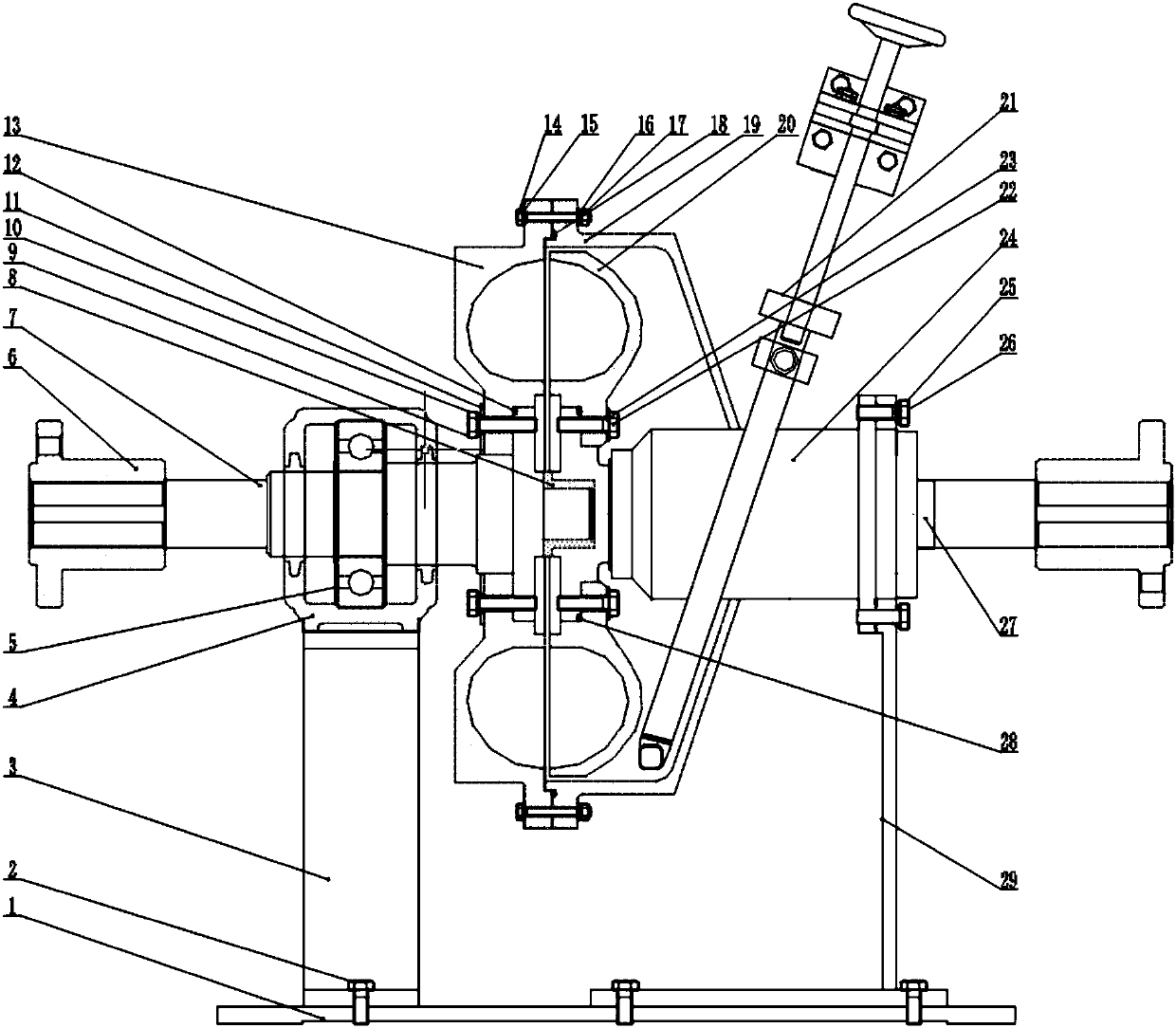

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

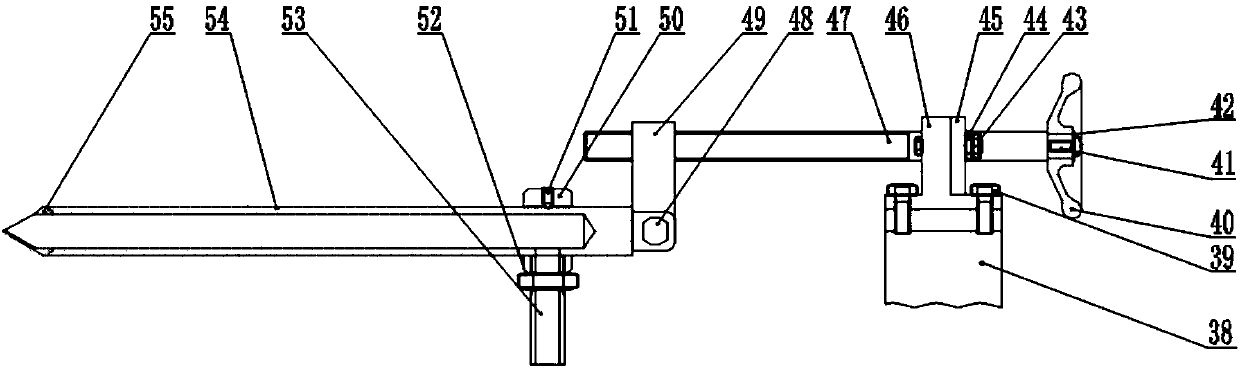

[0025]A high-strength transparent hydraulic coupling device for PIV testing, the device includes a mounting base plate 1, a vertical bearing support bracket 3 is fixed on the mounting base plate 1 through No. 1 hex head bolts 2, and the input end of the input shaft 7 passes through Coupling 6 is connected with the starter motor, the edge of the outer ring of deep groove ball bearing 5 is stuck in the groove of the inner edge of bearing seat 4 on bearing seat bracket 3, and deep groove ball bearing 5 is transitionally fitted with input shaft 7, so that the input shaft 7 Supported on the bearing housing 4, the outer wall of the pump wheel 13 is processed into a plane along the radial direction of the pump wheel 13 and a cylindrical surface along the axial direction of the pump wheel 13, and the angle between the joint of the plane and the cylindrical surface It is 90 degrees to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com