Anti-deformation rectifiable foundation applicable to wind turbine generator in goaf site, and construction method thereof

A wind turbine, anti-deformation technology, applied in infrastructure engineering, construction, etc., can solve the problems of inability to resist residual deformation, unclear concept of gravel layer, viscous and slidable layer ineffective, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

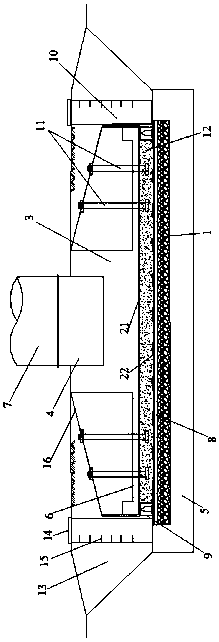

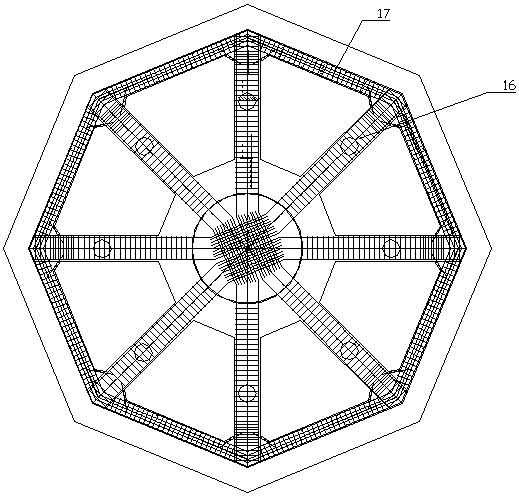

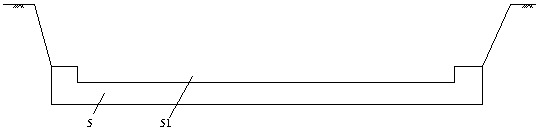

[0026] An anti-deformation and correctable foundation suitable for wind turbines in goaf sites, such as figure 1 and figure 2 As shown, the excavated foundation pit is used to place the foundation, wherein the inner side wall of the foundation pit is inclined outward from bottom to top, and a concave deepening layer is set on the foundation 5 of the foundation pit, and the width of the deepening layer is smaller than that of the foundation 5 width, the depth of the deepening layer is 300~600mm.

[0027] Lay the gravel cushion 1 in the deepening layer, the thickness of the gravel layer is 300~600mm. Wherein, the crushed stone cushion layer 1 can use existing graded crushed stones, and the performance of graded crushed stones is more stable, which can ensure the bearing capacity of the crushed stone cushion layer 1 .

[0028] Concrete cushion 8 is laid on gravel cushion 1, and concrete cushion 8 thickness is 100mm, and the strength of concrete cushion 8 is not lower than C15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com