Band fabric with variable section diameter, core structure and appearance decorative pattern and manufacturing method thereof

A manufacturing method and variable cross-section technology, applied in the direction of fabrics, textiles, papermaking, textiles, etc., can solve the problems of monotonous fabric varieties and continuous repetition of patterns, etc., and achieve the effect of tight and stiff structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

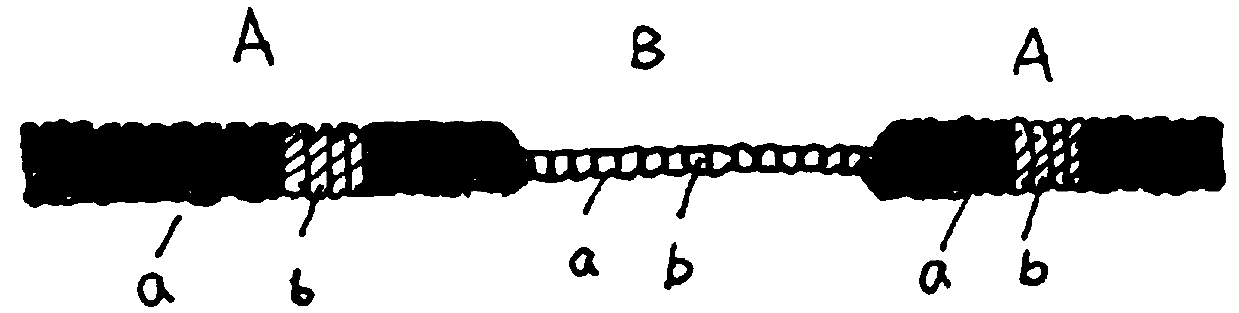

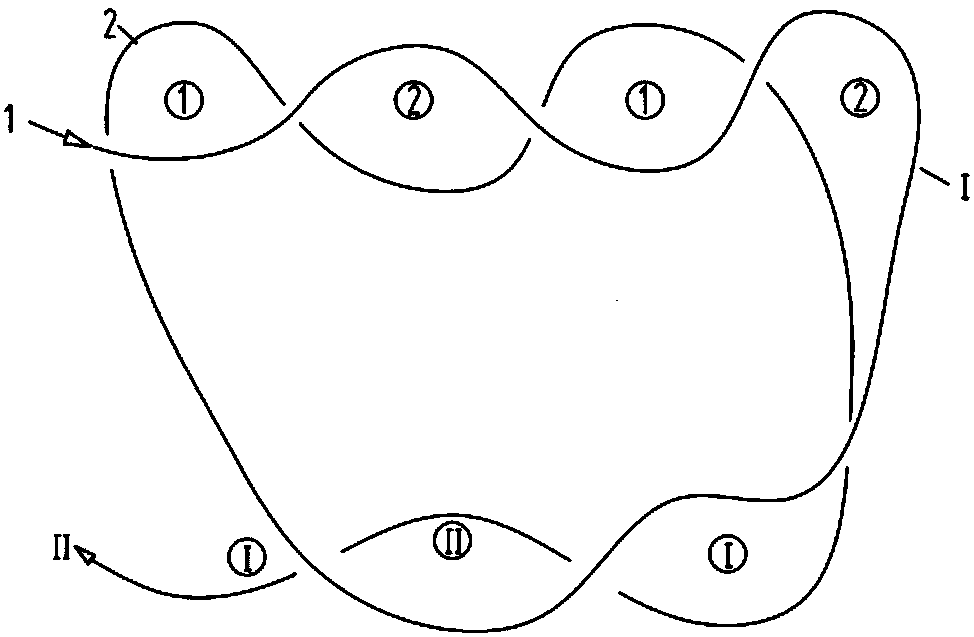

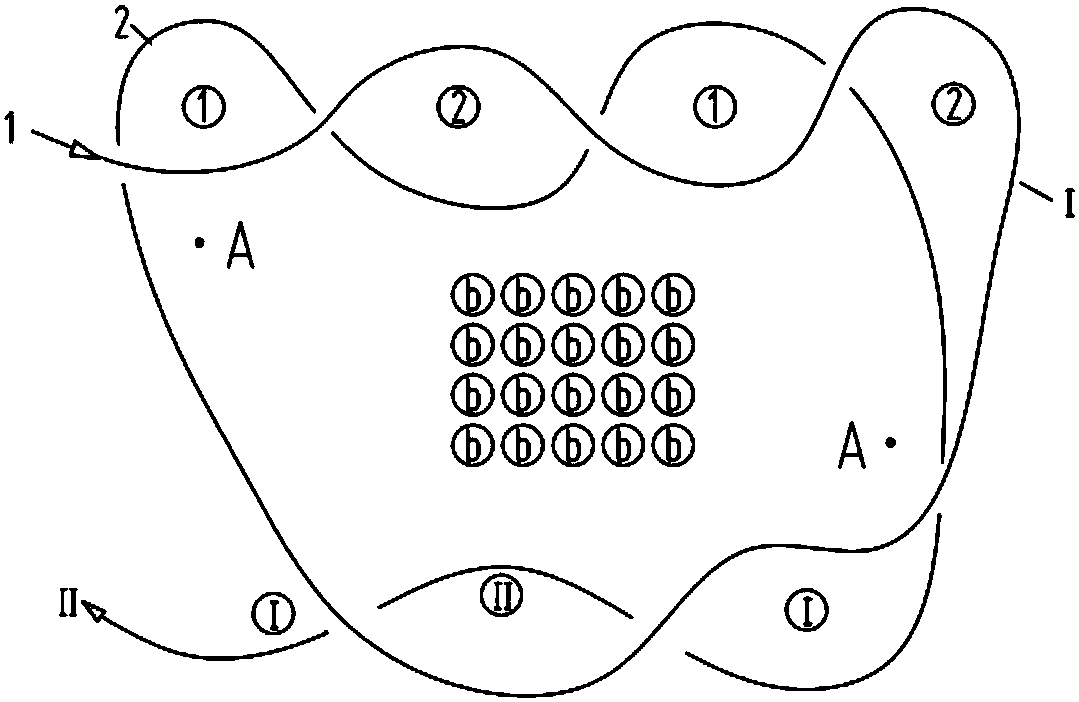

[0021] The surface pattern of the present invention is a tape fabric with variable cross-sectional diameter, core structure and appearance pattern of plain weave as follows.

[0022] On the basis of the traditional plain weaving tubular fabric weaving system, a set of warp yarn system composed of b-color yarn is added as the yarn core. When making the upper layer of the tubular fabric, this cover of warp yarns sinks together with another set of warp yarn systems participating in the weaving of the tubular lower layer, and does not participate in weaving. When making the lower layer of the tubular fabric, this cover of warp yarns floats together with another set of warp yarn systems participating in the weaving of the tubular upper layer, and does not participate in weaving. If jacquard is required, part of the b-colored yarn as the yarn core participates in the weaving of the upper and lower layers of the ribbon surface, instead of sinking or floating as a whole. During the w...

Embodiment 2

[0025] The surface pattern of the present invention is a tape fabric with variable section diameter, core structure and appearance pattern of twill weave as follows.

[0026] On the basis of the traditional tubular fabric weaving system with twill pattern on the surface, a set of warp yarn system composed of b-color yarn is added as the yarn core. When making the upper layer of the tubular fabric, this cover of warp yarns sinks together with another set of warp yarn systems participating in the weaving of the tubular lower layer, and does not participate in weaving. When making the lower layer of the tubular fabric, this cover of warp yarns floats together with another set of warp yarn systems participating in the weaving of the tubular upper layer, and does not participate in weaving. If jacquard products are required, part of the b-colored yarn as the yarn core participates in the weaving of the upper and lower layers of the ribbon surface, instead of sinking or floating as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com