Method for synergistically immobilizing L-arabinose isomerase and ionic liquid

A technology of ionic liquid and arabinose, applied in the direction of isomerase, immobilized on/in organic carrier, biochemical equipment and method, etc., can solve the problem of low enzyme production level, separation and purification of unfavorable products, large amount of addition, etc. problems, to achieve the effect of increasing the amount of enzyme protein immobilization, broad commercial application prospects, and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

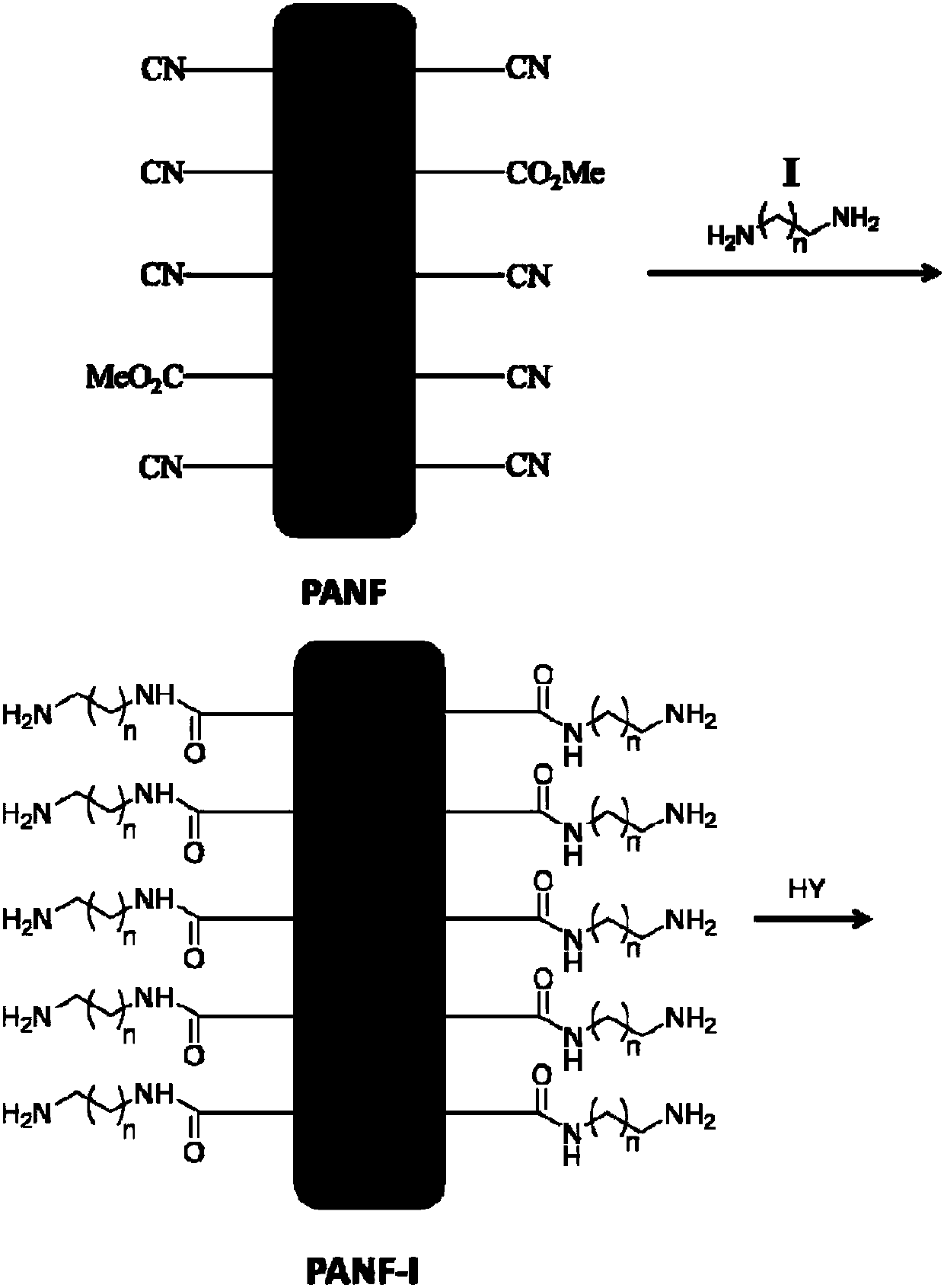

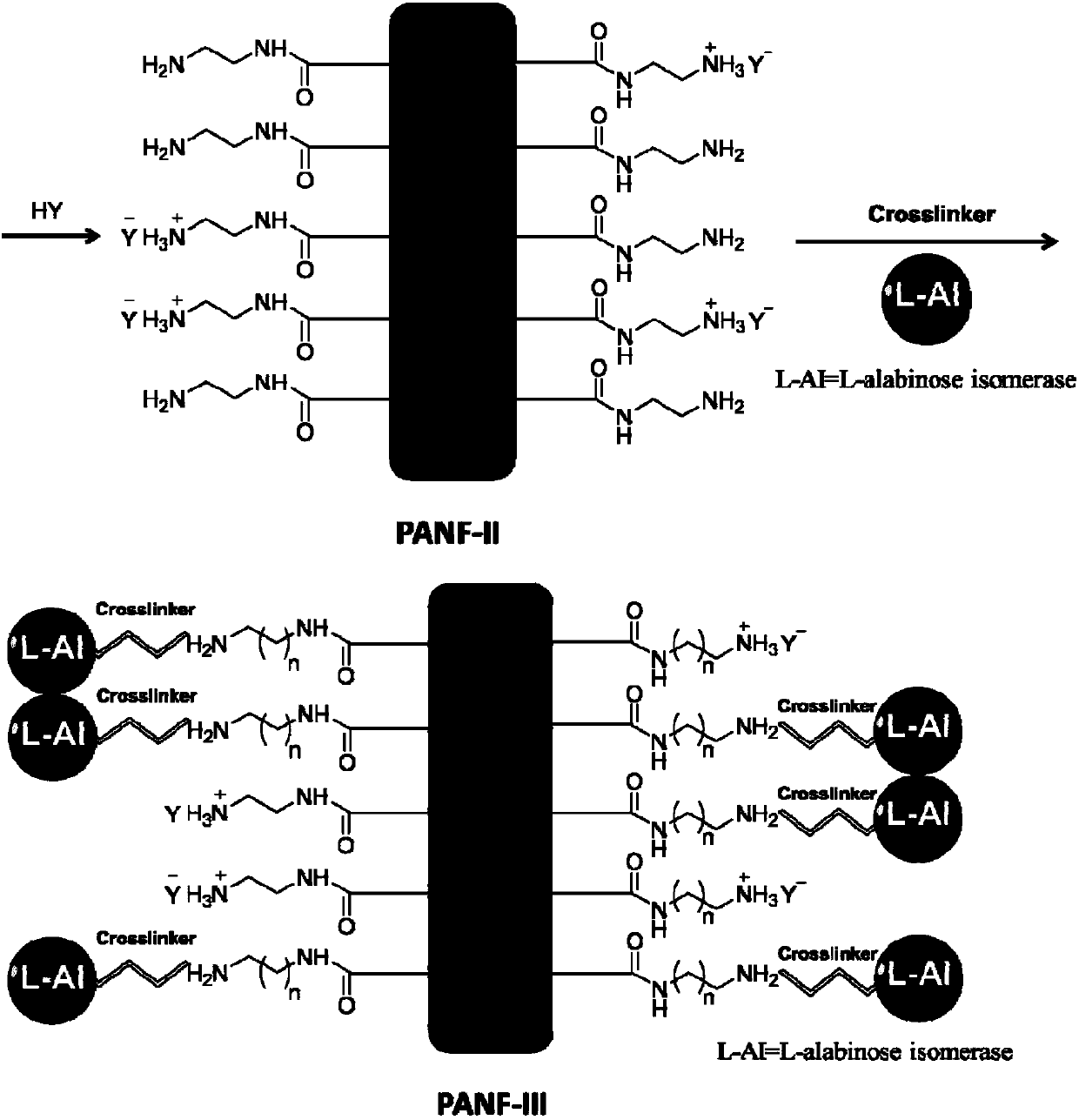

[0025] The preparation of step 1 PANF-I

[0026] Add 2.0g of dry acrylic fiber (PANF), ethylenediamine (0.12mol) and 30mL of deionized water into a 100mL three-neck flask, reflux for 4h under electromagnetic stirring, then take out the fiber sample, filter it with suction, and use a 60-70℃ Wash with water repeatedly until the lotion is neutral. After drying in the air, then vacuum-dry at 60°C for 12 hours to obtain PANF-I.

[0027] The preparation of step 2 PANF-II

[0028] Dried PANF-I was stirred in 1M, 2eq nitric acid solution for 3h at room temperature, and then the formed fiber-immobilized ionic liquid was taken out, filtered with suction, and rinsed with deionized water until neutral. After drying in the air, it was dried in vacuum (60°C) for 12h.

[0029] Step 3 Preparation of PANF-III

[0030] Add PANF-II and 5 mL of free enzyme solution to 28 mL of 0.5% glutaraldehyde aqueous solution, shake and cross-link at room temperature (25°C) for 1 h, pour off the solution,...

Embodiment 2

[0037] The preparation of step 1 PANF-I

[0038] Add 2.0g of dry acrylic fiber (PANF), 0.12mol of butanediamine and 30mL of deionized water into a 100mL three-neck flask, reflux for 4h under electromagnetic stirring, then take out the fiber sample, filter it with suction, and use 60-70℃ water Wash repeatedly until the lotion is neutral. After drying in the air, then vacuum-dry at 60°C for 12 hours to obtain PANF-I.

[0039] The preparation of step 2 PANF-II

[0040] Dried PANF-I was stirred in 1M, 2eq sulfuric acid solution at room temperature for 3h, and then the formed fiber-immobilized ionic liquid was taken out, filtered with suction, and rinsed with deionized water until neutral. After drying in the air, it was dried in vacuum (60°C) for 12h.

[0041] Step 3 Preparation of PANF-III

[0042] Add PANF-II and 5 mL of free enzyme solution to 28 mL of 0.5% glutaraldehyde aqueous solution, shake and cross-link at room temperature (25°C) for 1 h, pour off the solution, and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com