Polyester resin for high filling mark covering powder paint and preparation method thereof

A polyester resin and powder coating technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of increased equipment loss, prolonged process, increased maintenance requirements, etc., to prevent oxidation side reactions and achieve excellent surface performance. , the effect of increasing the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

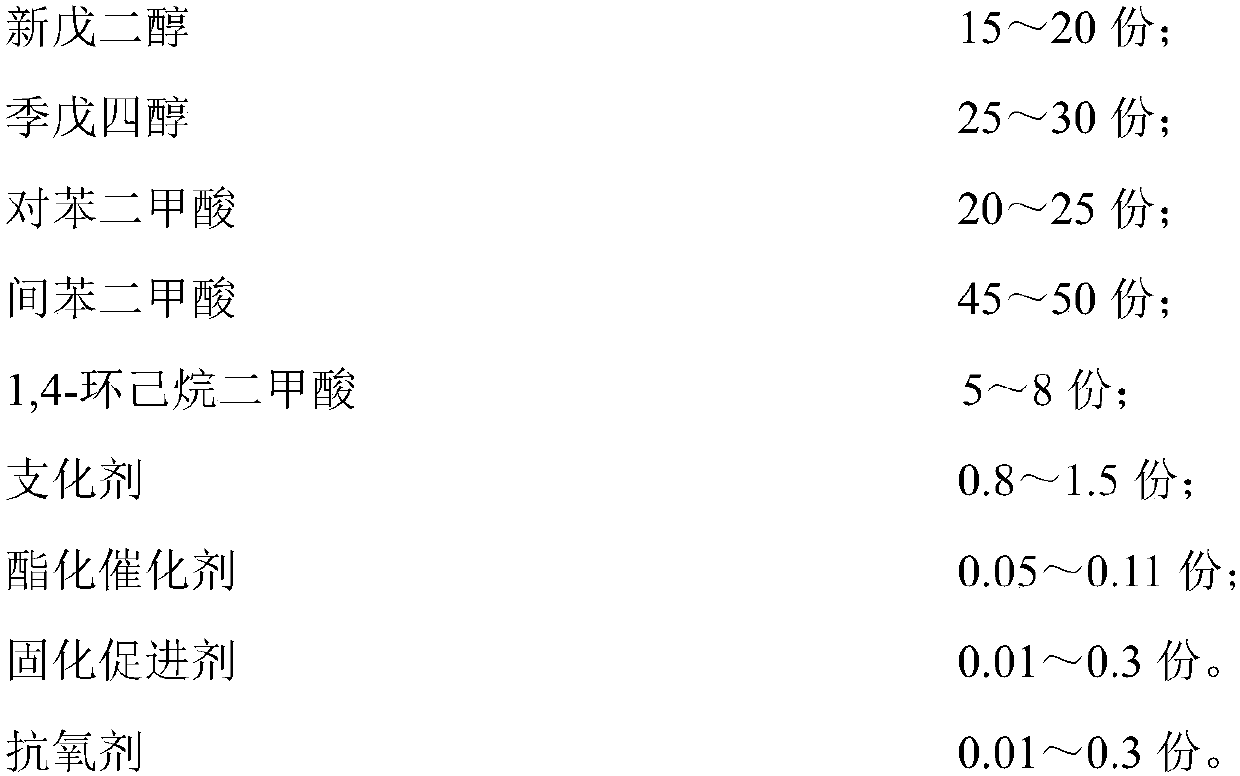

[0040] A polyester resin for high-filling and concealing powder coatings is prepared from the following components in parts by weight:

[0041]

[0042] Wherein, the branching agent is trimethylolpropane. The esterification catalyst is a mixture of dibutyltin oxide and monobutyltin oxide, and the mass ratio of the two is 1:1.5. The curing accelerator is a mixture of tetrabutylammonium chloride and ethyltriphenylphosphine bromide, and the mass ratio of the two is 1:1. The antioxidant is a mixture of antioxidant 3114 and antioxidant 168, and the mass ratio of the two is 2:1.

[0043] Above-mentioned a kind of preparation method of polyester resin for high-filling and hiding trace powder coating, concrete steps are as follows:

[0044] (1) Add neopentyl glycol, pentaerythritol, 1,4-cyclohexanedicarboxylic acid, branching agent and esterification catalyst in sequence into the reaction kettle containing the water agent, continue to pass nitrogen, and heat up to 240°C, Stir th...

Embodiment 2

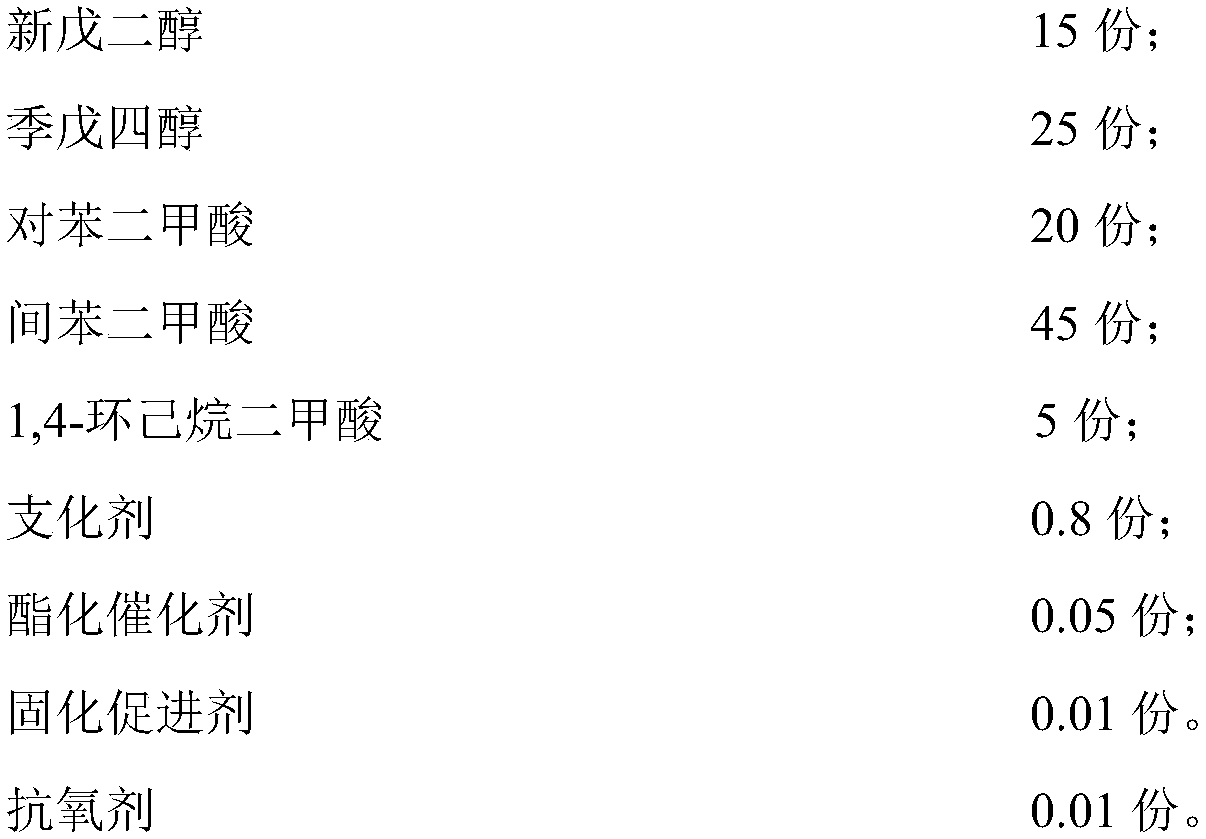

[0053] A polyester resin for high-filling and concealing powder coatings is prepared from the following components in parts by weight:

[0054]

[0055] Wherein, the branching agent is trimethylolethane. The esterification catalyst is a mixture of dibutyltin oxide and monobutyltin oxide, and the mass ratio of the two is 1:1.5. The curing accelerator is a mixture of tetrabutylammonium chloride and ethyltriphenylphosphine bromide, and the mass ratio of the two is 1:1. The antioxidant is a mixture of antioxidant 3114 and antioxidant 168, and the mass ratio of the two is 2:1.

[0056] Above-mentioned a kind of preparation method of polyester resin for high-filling and hiding trace powder coating, concrete steps are as follows:

[0057] (1) Add neopentyl glycol, pentaerythritol, 1,4-cyclohexanedicarboxylic acid, branching agent and esterification catalyst in sequence into the reaction kettle containing the water agent, continue to pass nitrogen, and heat up to 250°C, Stir the...

Embodiment 3

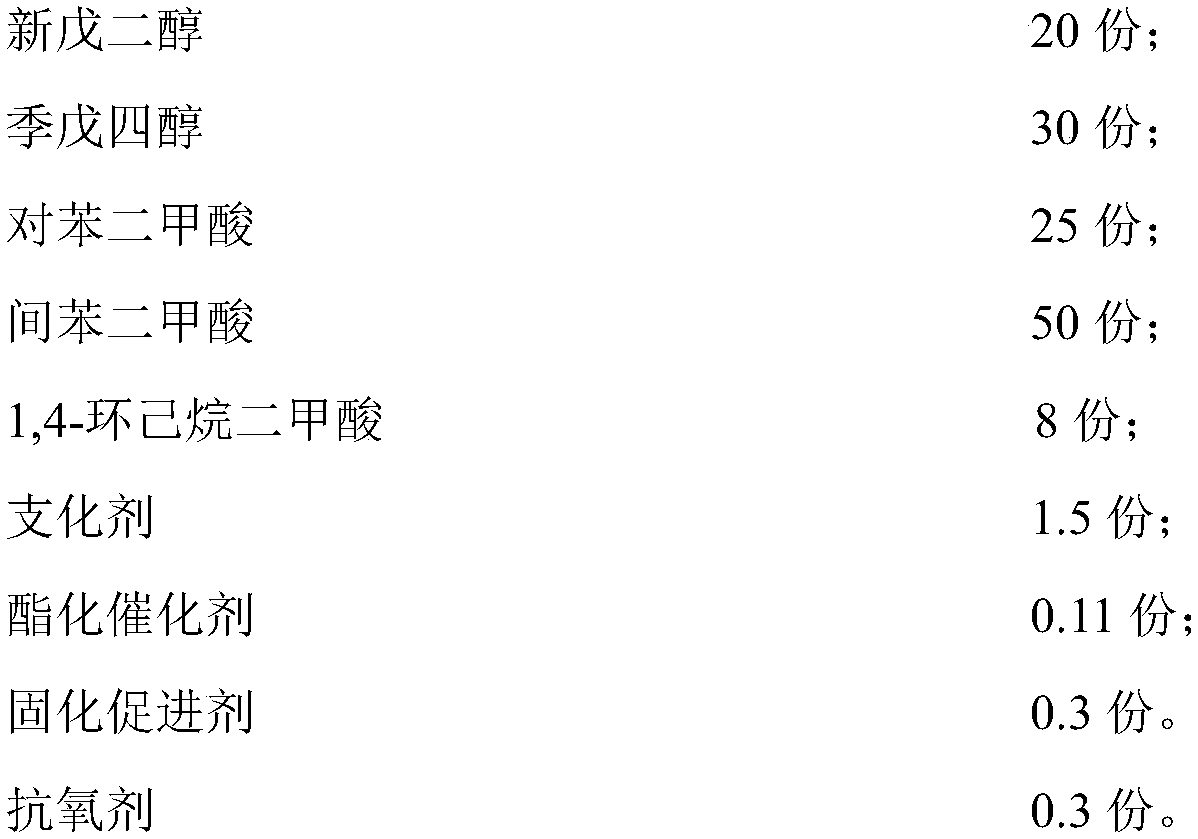

[0066] A polyester resin for high-filling and concealing powder coatings is prepared from the following components in parts by weight:

[0067]

[0068] Wherein, the branching agent is pentaerythritol. The esterification catalyst is a mixture of dibutyltin oxide and monobutyltin oxide, and the mass ratio of the two is 1:1.5. The curing accelerator is a mixture of tetrabutylammonium chloride and ethyltriphenylphosphine bromide, and the mass ratio of the two is 1:1. The antioxidant is a mixture of antioxidant 3114 and antioxidant 168, and the mass ratio of the two is 2:1.

[0069] Above-mentioned a kind of preparation method of polyester resin for high-filling and hiding trace powder coating, concrete steps are as follows:

[0070] (1) Add neopentyl glycol, pentaerythritol, 1,4-cyclohexanedicarboxylic acid, branching agent and esterification catalyst in sequence into the reaction kettle containing the water agent, continue to pass nitrogen, and heat up to 250°C, Stir the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com