Nanometer biological health-preserving composite material and preparation method thereof

A composite material and biological technology, used in phototherapy, radiotherapy, clay products, etc., can solve the problems of difficult operation, destroy the natural characteristics of scraping boards, and long production process, and achieve easy to master, improve human microcirculation and operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Take each raw material according to Table 1, pass through a 200-mesh standard sieve after pulverizing respectively, put into the sedimentation tank after mixing uniformly and carry out aging for 15 days, then pass through the vacuum refinement of the mud mill for 3 hours to obtain the mud material; put the mud material in The slurry was melted in a high-level pulp barrel, then poured into the mold, and dried at room temperature with the mold for 3 weeks to obtain a green body, and then glazed on the surface of the green body, and fired in a box at 1000°C to obtain the ironing board.

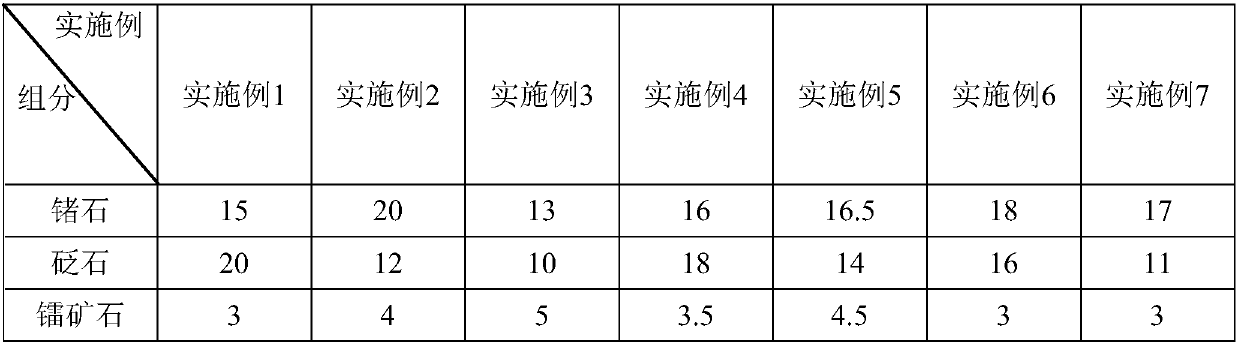

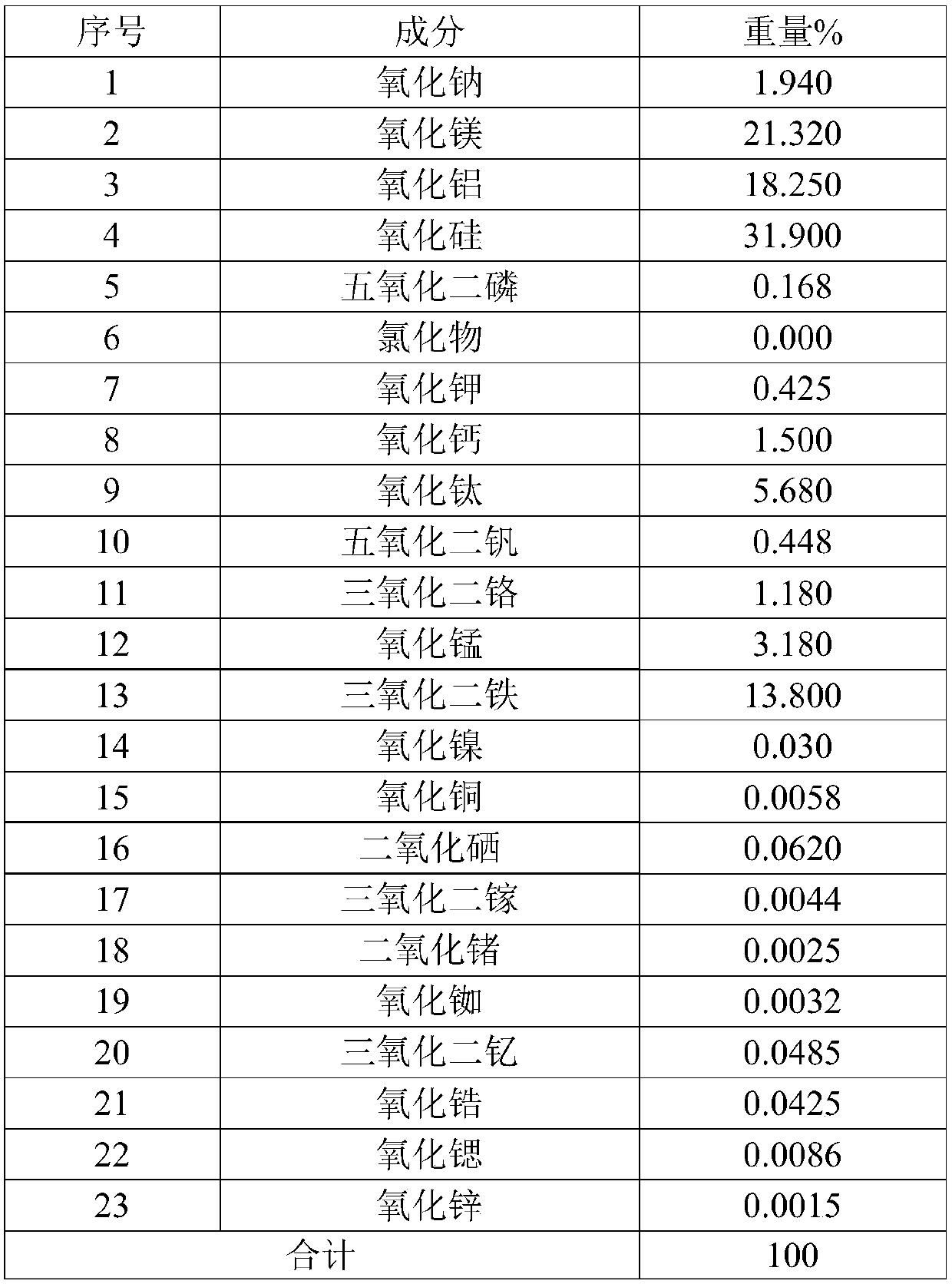

[0049] Each component of table 1 is used amount table (weight %)

[0050]

[0051]

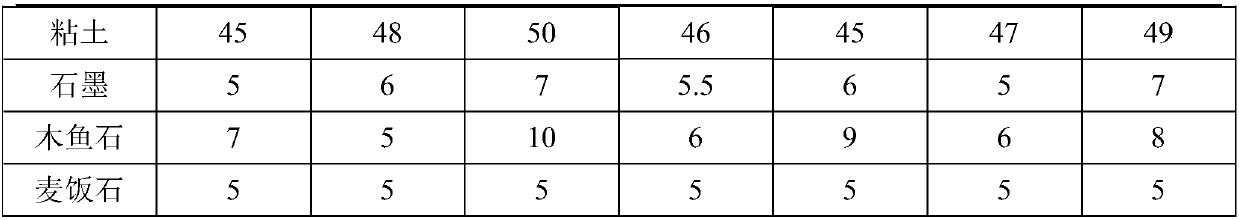

[0052] The obtained nanometer biological scraping ironing board is detected, and its chemical component content is as follows:

[0053] Table 2 The test results of the chemical components of the nano-biological scraper and ironing board

[0054]

[0055] As can be seen from Table 2, the nano-biol...

Embodiment 2

[0060] Weigh each raw material according to Table 1, pass through a 100-mesh standard sieve after pulverizing respectively, put into the sedimentation tank after mixing uniformly and carry out aging for 15 days, then pass through the vacuum refinement of the mud mill for 2 hours to obtain the mud material; put the mud material in The slurry was melted in a high-level pulp barrel, then poured into the mold, and dried at room temperature with the mold for 1 week to obtain a green body, and then glazed on the surface of the green body, and fired at 1100°C in a box to obtain the ironing board.

[0061] The size of the obtained nano-biological ironing board is 104*50mm, the thickness is 11.5mm; the color is black; the specific gravity is 2.0g / cm 3 ; Water absorption rate: 0.5%; Infrared emission rate: 8-18μm, ε>90%; Specific heat capacity: 2.9J / (kg·℃); Anion content: 2000±500 / cm 3 .

[0062] The natural stone in the nano-biological scraping and ironing board of the present inventi...

Embodiment 3

[0065] Take each raw material according to Table 1, pass through a 100-mesh standard sieve after pulverizing respectively, put into the sedimentation tank after mixing evenly and carry out aging for 15 days, and then pass through the vacuum refining of the mud mill for 3 hours to obtain the mud; put the mud in The slurry was melted in a high-level pulp barrel, then poured into the mold, and dried at room temperature with the mold for 1 week to obtain a green body. Afterwards, the surface of the green body was glazed, and the box was fired at 1050°C to obtain the ironing hot moxibustion particles.

[0066] The method of using the nano-biological ironing moxibustion particles is as follows. The ironing moxibustion particles are first frozen, and then directly contacted with the affected area after being taken out, or put in a bag and covered on the surface of the affected area.

[0067] Ironing hot moxibustion granules are packed in a bag and placed in the ice room of the refrige...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| specific heat capacity | aaaaa | aaaaa |

| specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com