Up-to-standard septic tank

A manure tank and manure residue technology, which is applied in chemical instruments and methods, biological water/sewage treatment, biological sludge treatment, etc. Simple structure and the effect of strengthening the effect of denitrification and denitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

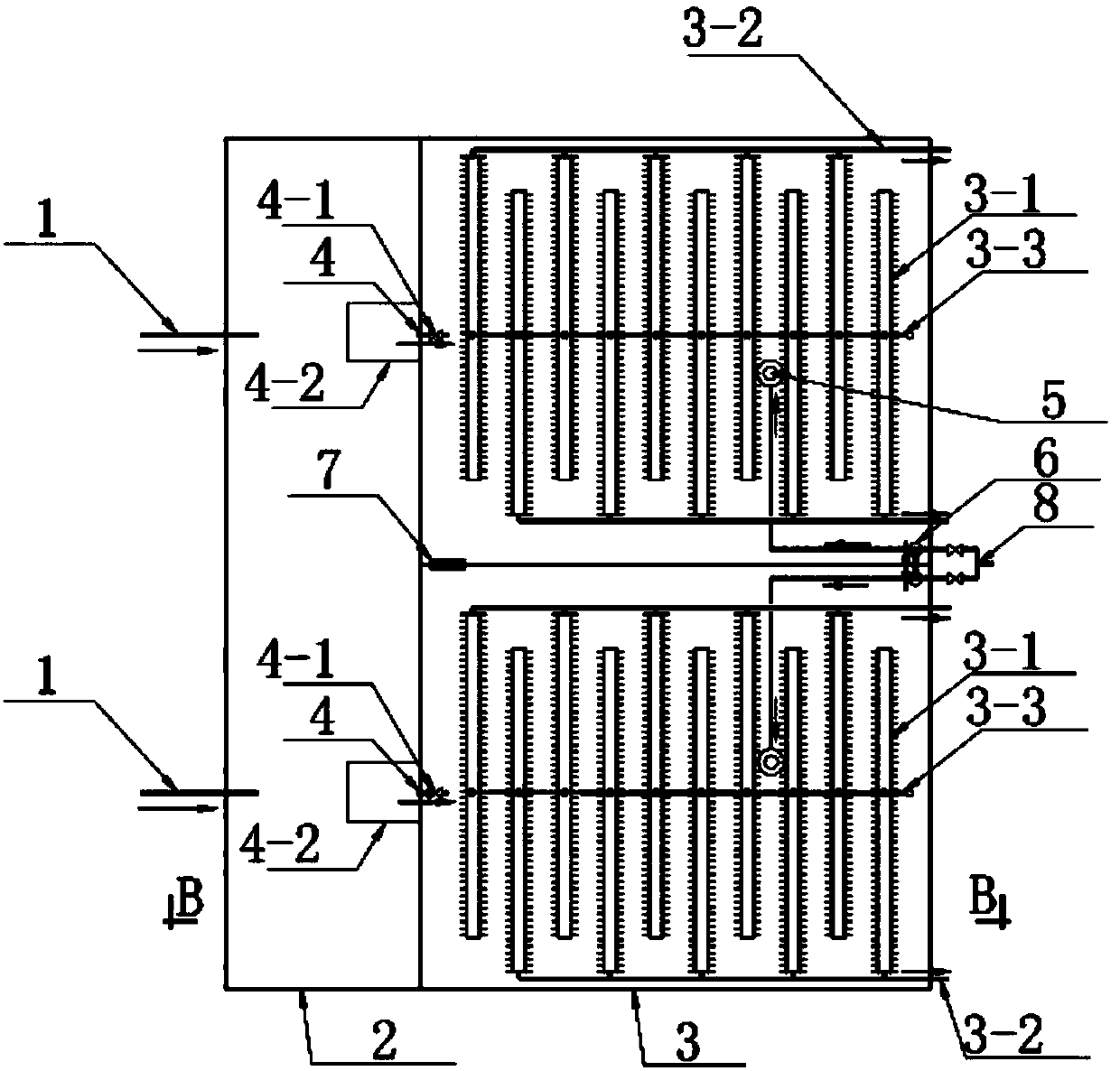

[0028] Up to standard septic tank. Its main structures include a septic tank 2 and a biological contact oxidation filtration sedimentation tank 3; a channel I3 is set between the septic tank 2 and the biological contact oxidation filtration sedimentation tank, and a grid 4-2 is set on the side of the channel I3 near the septic tank 2; After being treated in the slag tank 2, the sewage enters the biological contact oxidation filtration sedimentation tank 3 from the channel I4, in which large solid pollutants are intercepted in the septic tank 2, and the sewage is filtered, precipitated and biochemically processed in the biological contact oxidation filtration sedimentation tank 3. Function to remove pollutants and increase dissolved oxygen in effluent.

[0029] The present invention comprises the following steps when reaching the lower effluent standard requirements:

[0030] (1) Sediment: Sewage enters the slag tank 2 through the water inlet pipe, settles in the slag tank 2 a...

Embodiment 2

[0035] Grade A septic tank. Its main structures include septic tank 2 and bio-contact oxidation filtration sedimentation tank 3; channel I4 is set between septic tank 2 and biological contact oxidation filtration sedimentation tank, and grille 4-2 is set on the side of channel I4 close to septic tank 2; sewage After being treated in the slag tank 2, it enters the biological contact oxidation filtration sedimentation tank 3 from channel I4, in which large solid pollutants are intercepted in the septic tank 2 for sedimentation or floated up for removal, and the sewage is filtered and precipitated in the biological contact oxidation filtration sedimentation tank 3 and biochemical action to remove pollutants and increase dissolved oxygen in effluent.

[0036] An aeration system 5 is provided in the biological contact oxidation filtration sedimentation tank 3 to increase the dissolved oxygen content to cause aerobic biochemical reaction to degrade pollutants in the domestic sewage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com