Efficient rubber cooling machine

A cooling machine and rubber technology, applied in the field of rubber production equipment, can solve the problems of energy waste, poor cooling effect, low cooling efficiency of the cooling machine, etc., and achieve the effect of reducing the difficulty of cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

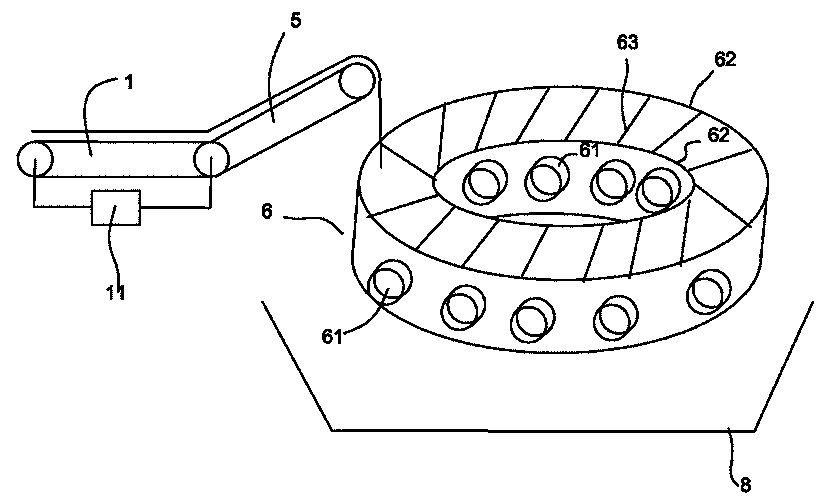

[0027] Such as Figures 1 to 4 The high-efficiency rubber cooling machine shown includes a feed conveyor belt 1, a lifting conveyor belt 5 connected to the feeding conveyor belt 1, and a circulating cooler 6 arranged below the lifting conveyor belt 5.

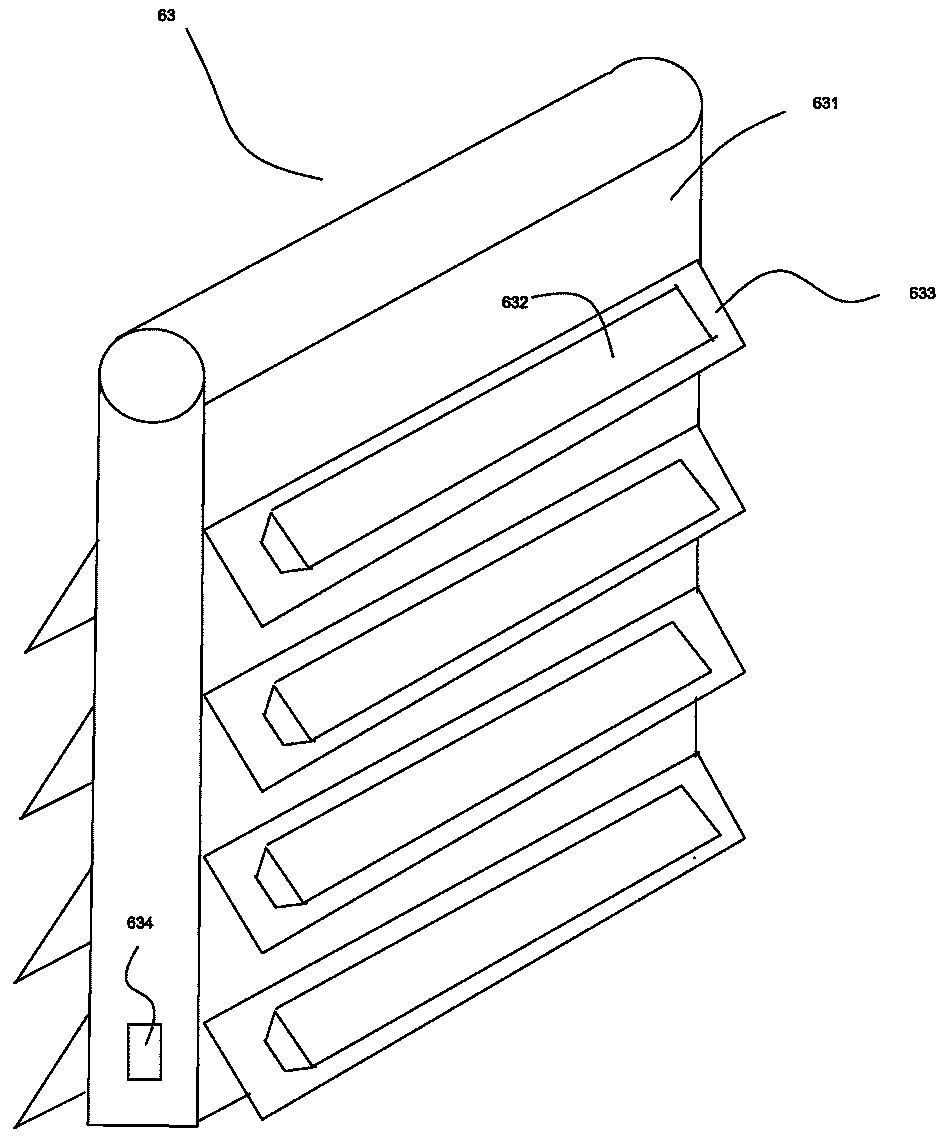

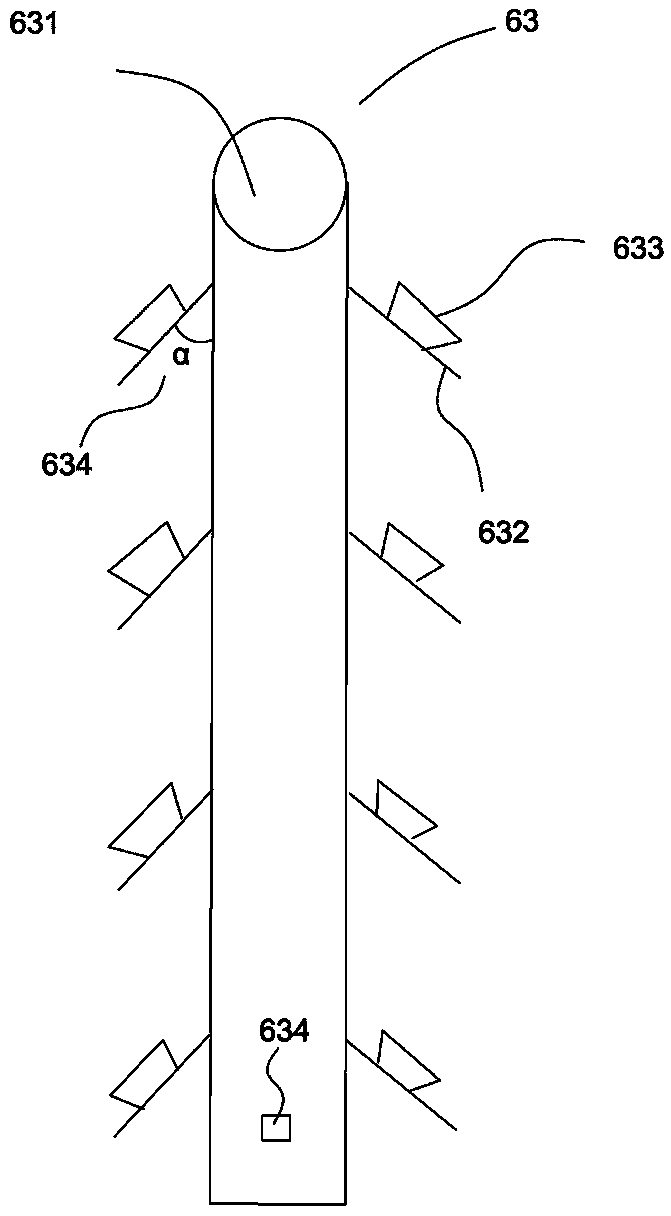

[0028] The feed conveyor belt 1 is provided with a speed controller 11, and the recirculating cooler 6 includes a support 62 that is oppositely arranged and installed with an air cooling structure 61 and a plurality of suspension structures 63 that can circulate and move between the support 62, and the suspension structure includes a moving plate 631. A plurality of supporting plates 632 are arranged on both sides of the moving plate 631 to support the rubber. The supporting plates prevent the rubber from sticking together, so that both sides can be cooled by the air cooling structure. Between the supporting plate 632 and the moving plate 631 An included angle α634 is formed between them, and the included angle α634 can be adju...

Embodiment 2

[0036] Such as Figures 2 to 5 The high-efficiency rubber cooling machine shown includes a feed conveyor belt 1, a lifting conveyor belt 5 connected to the feeding conveyor belt 1, and a circulating cooler 6 arranged below the lifting conveyor belt 5. The difference from Example 1 is:

[0037] It also includes a roller conveying platform 2, which is arranged behind the lifting conveyor belt 5, and a circulating cooler 6 is arranged below the roller conveying platform 2.

[0038] A liquid collection pool 8 is provided below the circulating cooler 6 and the roller conveying platform 2 .

[0039] The roller conveyor table 2 is provided with a plurality of rollers 21, and the rollers 21 are provided with a driver 22 for driving the rollers 21 to rotate. The rollers on the roller platform are arranged at intervals, and the upper and lower surfaces of the rubber can be in contact with the air, which plays a role in pre-cooling, and can play a role in stretching the rubber, prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com