An integrated device for sizing and shaping cloth

A cloth feeding device and cloth technology, which is applied in the direction of processing textile material carriers, processing textile material equipment configuration, removing liquid/gas/steam, etc., can solve the problem of not considering the effect of size on the conjunctiva and saving size problems and other problems, to achieve the effect of reducing production costs and uniform conjunctiva

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

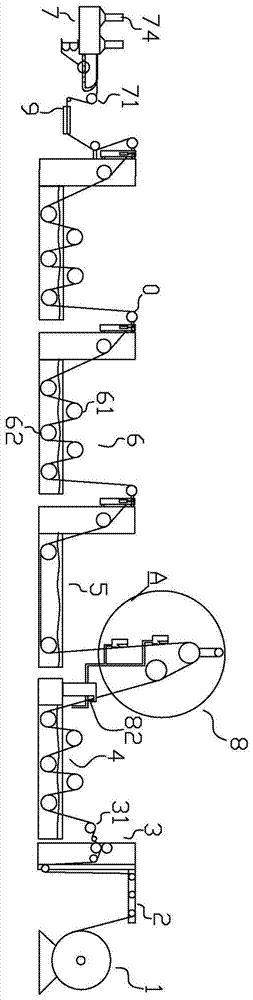

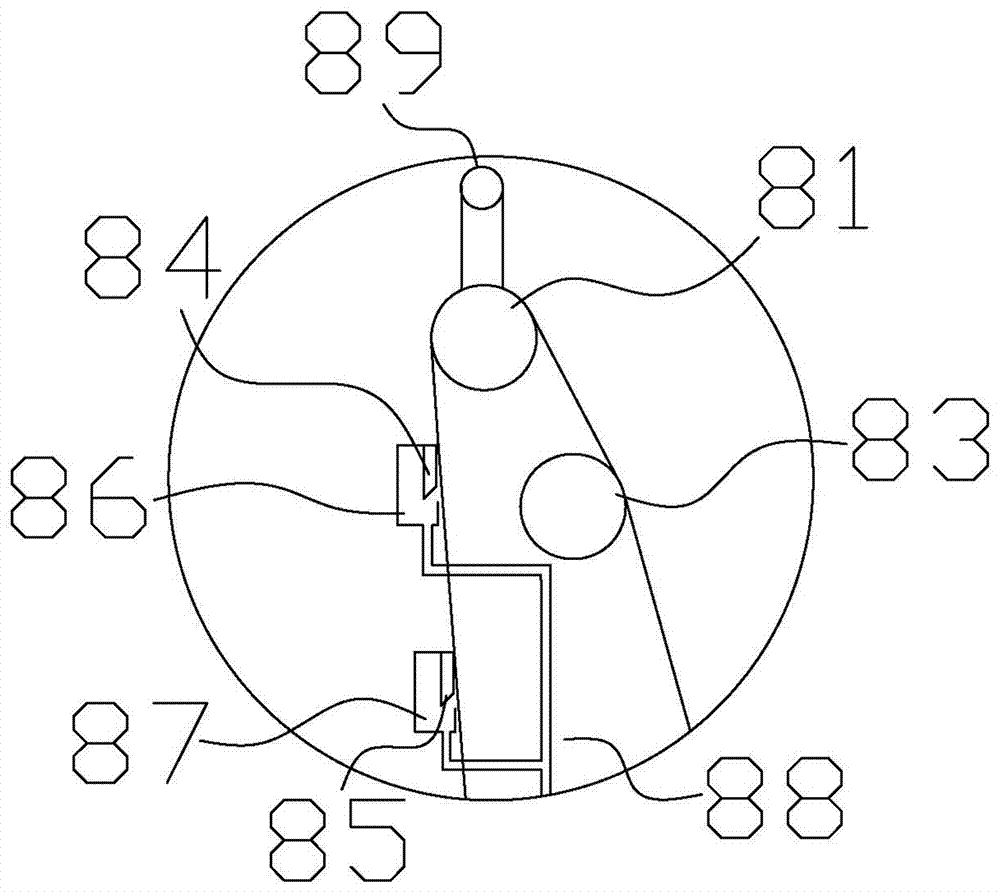

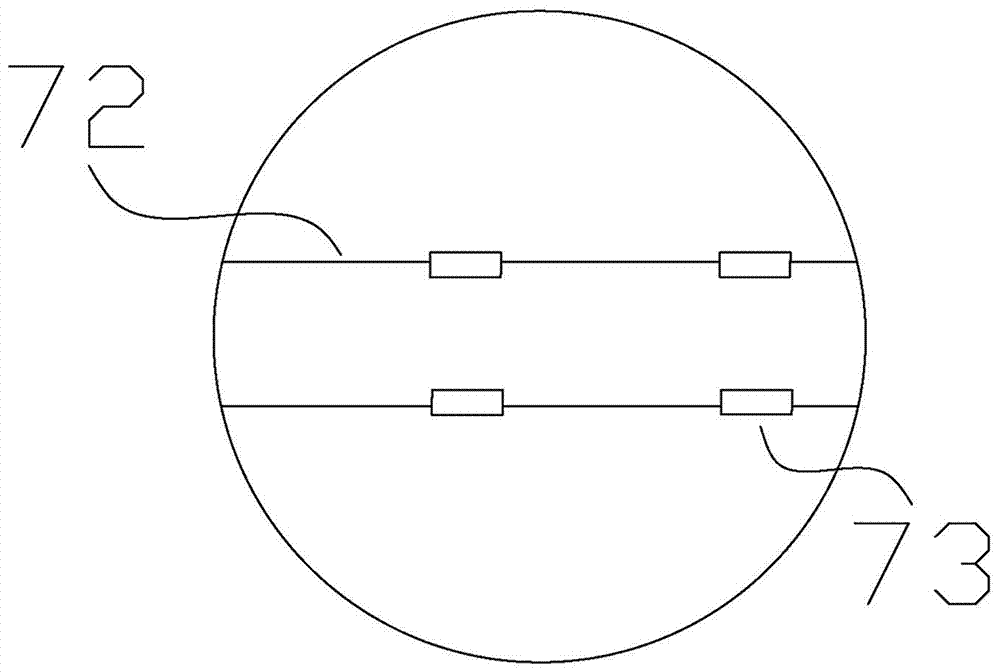

[0032] Embodiment 1: An integrated device for sizing and shaping cloth, which sequentially includes a cloth feeding device 1, a cloth feeding rolling car 2, a cloth feeding opening device 3, a slurry tank 4, a conjunctiva tank 5, two washing tanks 6 and a drying Device 7, a squeegee recovery device 8 is arranged between the cloth feeding and opening device 3 and the slurry tank 4, and the squeegee recovery device 8 includes a homogenizing roller 81 positioned higher than the slurry tank 4 , the cloth is stretched and moved between the homogenizing roller 81, the slurry pool 4, and the conjunctival pool 5; the cloth surface between the homogenizing roller 81 and the slurry pool 4 is set There is a rough scraper 82, and an auxiliary homogenizing roller 83 is arranged below the homogenizing roller 81, and the auxiliary homogenizing roller 83 is closer to the slurry tank 4 than the homogenizing roller 81 in a horizontal position, and the A middle scraper 84 and a fine scraper 85 a...

Embodiment 2

[0035]Embodiment 2: An integrated device for sizing and shaping cloth, which sequentially includes a cloth feeding device 1, a cloth feeding rolling car 2, a cloth feeding opening device 3, a slurry tank 4, a conjunctiva tank 5, two washing tanks 6 and a drying Device 7, a squeegee recovery device 8 is arranged between the cloth feeding and opening device 3 and the slurry tank 4, and the squeegee recovery device 8 includes a homogenizing roller 81 positioned higher than the slurry tank 4 , the cloth is stretched and moved between the homogenizing roller 81, the slurry pool 4, and the conjunctival pool 5; the cloth surface between the homogenizing roller 81 and the slurry pool 4 is set There is a rough scraper 82, and an auxiliary homogenizing roller 83 is arranged below the homogenizing roller 81, and the auxiliary homogenizing roller 83 is closer to the slurry tank 4 than the homogenizing roller 81 in a horizontal position, and the A middle scraper 84 and a fine scraper 85 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com