Casting grinding equipment

A casting and equipment technology, applied in the field of casting grinding equipment, can solve the problems that easily affect the efficiency of production and processing, unfavorable efficiency, slow manual grinding, etc., and achieve the effect of improving the grinding effect, prolonging the service life and avoiding displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further detailed explanation through specific implementation mode below:

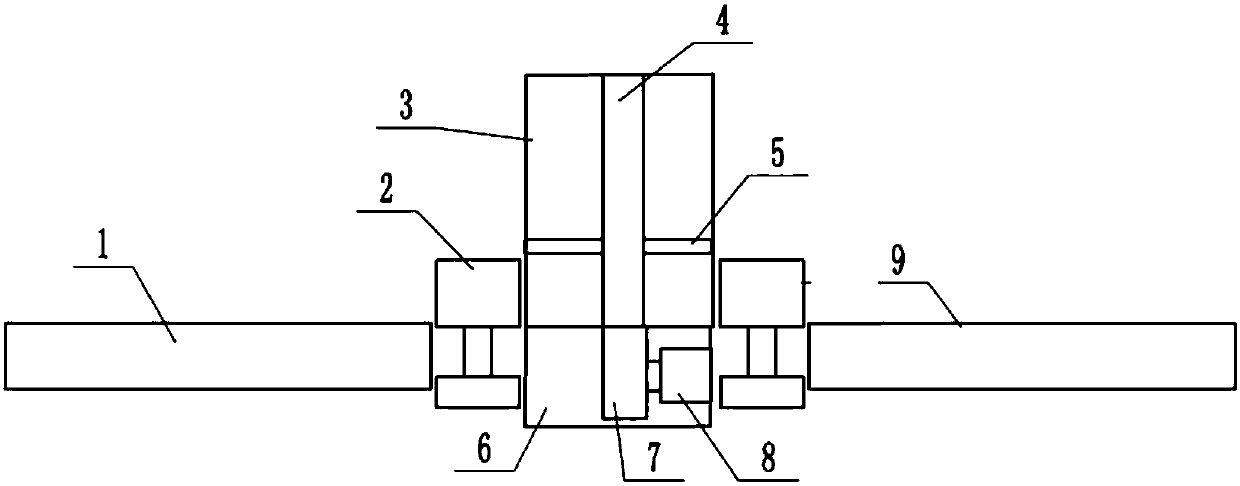

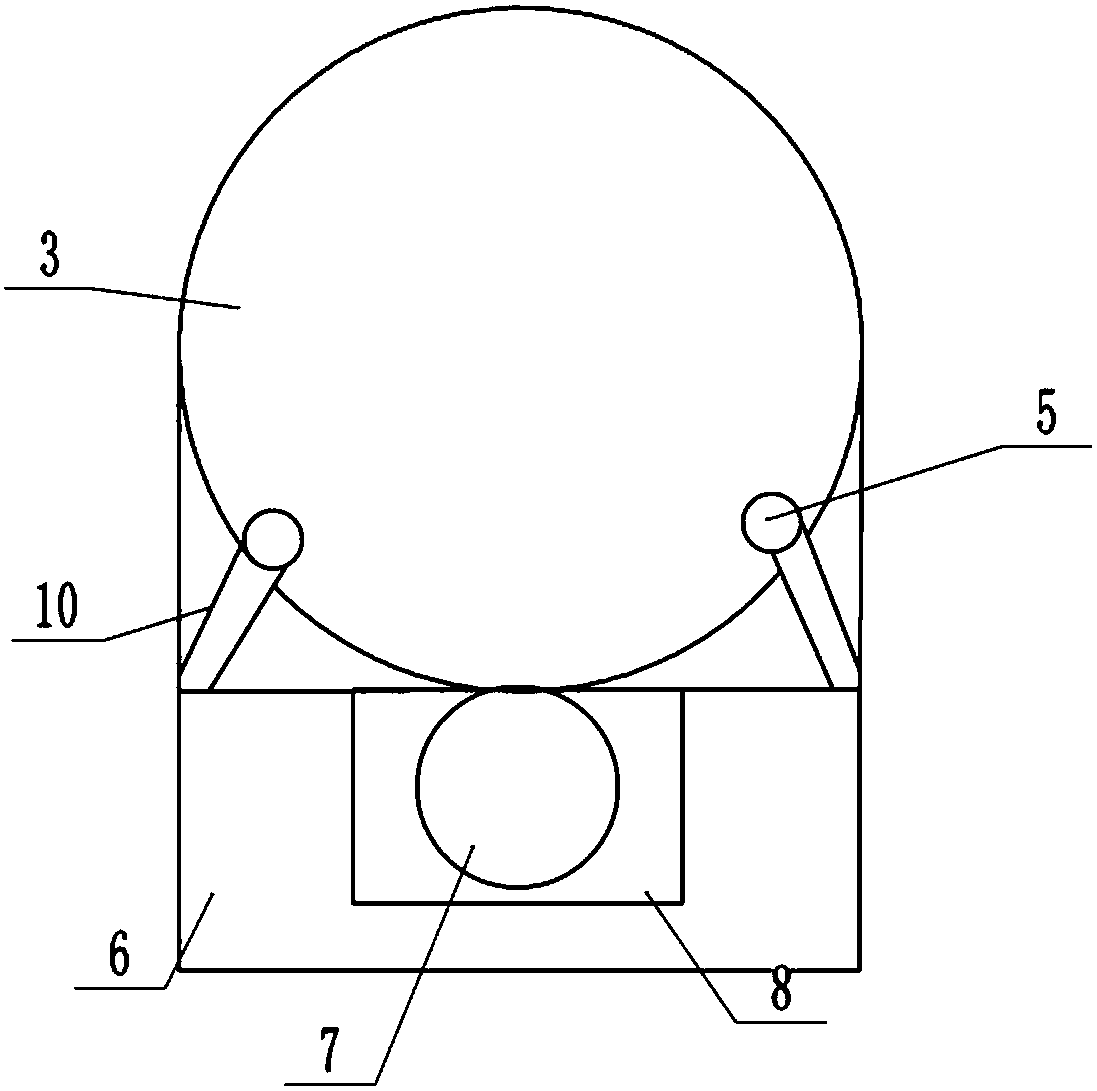

[0014] The reference numerals in the accompanying drawings of the description include: the first conveyor belt 1, the lifting platform 2, the grinding ring 3, the slave gear 4, the stop rod 5, the base 6, the main gear 7, the motor 8, the second conveyor belt 9, and the pole 10.

[0015] The embodiment is basically as attached figure 1 , figure 2 Show:

[0016] Casting grinding equipment, including a first conveyor belt 1 and a second conveyor belt 9 for transporting castings, a grinding mechanism is provided between the first conveyor belt 1 and the second conveyor belt 9, the grinding mechanism includes a base 6, and the upper surface of the base 6 is arc-shaped The concave cavity is provided with an arc-shaped through groove, and the concave cavity is rotated with a grinding ring 3 with a frosted inner surface. The concave cavity of the base 6 and the outer surface of the grinding ring 3 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com