Dark soy sauce and making method thereof

A technology for soy sauce and dark color, which is applied in the field of dark soy sauce and its brewing to achieve the effect of improving chroma, unique flavor and health care function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

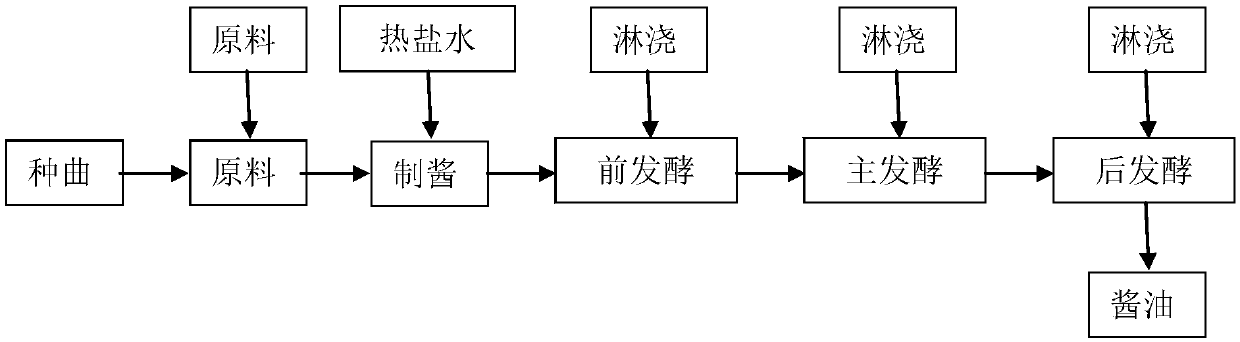

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 black tea fermentation bacteria is used for the production of dark soy sauce

[0031] Wash the black tea strains stored on the 5Bé wort slant medium containing 2% agar with physiological saline to prepare a spore suspension, take 10ml and insert it into 200g bran koji with a water content of 55% after sterilization, Cultivate at 30°C for 14 days to obtain mature bran koji.

[0032]Put 500g of soybean meal in a container, add 500ml of water, cook for 30min, add 70g of salt, cool to room temperature, add 150g of the above-mentioned bran koji, stir evenly and place it at 40°C for constant temperature fermentation, the fermentation time is 60d, and stir once every other day . After the fermentation, the supernatant was separated by centrifugation for component analysis. The results are shown in Table 1:

[0033] Numbering

Embodiment 2

[0034] Embodiment 2 black tea fermentation bacteria are used for the production of dark soy sauce

[0035] Wash the black tea strains stored on the 5Bé wort slant medium containing 2% agar with physiological saline to prepare a spore suspension, take 10ml and insert it into 200g bran koji with a water content of 55% after sterilization, Cultivate at 30°C for 14 days to obtain mature bran koji.

[0036] Take 500g of soybean meal in a container, add 500ml of water, cook for 30 minutes, add 70g of salt, cool to room temperature, add 100g of black tea fungus bran koji, 50g of commercial soy sauce koji, stir evenly and place it at 40°C for constant temperature fermentation, fermentation time For 60d, stir once every other day. After the fermentation, the supernatant was separated by centrifugation for component analysis. The results are shown in Table 2:

[0037] Numbering

Embodiment 3

[0038] The soy sauce production of the common commercial koji of embodiment 3 control group

[0039] Take 500g of soybean meal in a container, add 500ml of water, cook for 30min, add 70g of salt, cool to room temperature, add 50g of commercial soy sauce koji, stir well and place it at 40°C for constant temperature fermentation, the fermentation time is 60d, and stir once every other day . After the fermentation, the supernatant was separated by centrifugation for component analysis. The results are shown in Table 3:

[0040] Numbering

[0041] From the soy sauce quality comparison data analysis in the embodiment, black tea fungus soy sauce koji can completely replace and partly replace commercial product Aspergillus oryzae soy sauce koji for the production of soy sauce, and the chromaticity of finished product has increased to a great extent than the control value, shows The method can meet the technological needs of directly brewing dark soy sauce.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com