Homoallyl halide composition and method for storing homoallyl halide

A composition and halide technology, applied in chemical instruments and methods, disproportionation separation/purification of halogenated hydrocarbons, organic chemistry, etc., can solve problems such as polymerization and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

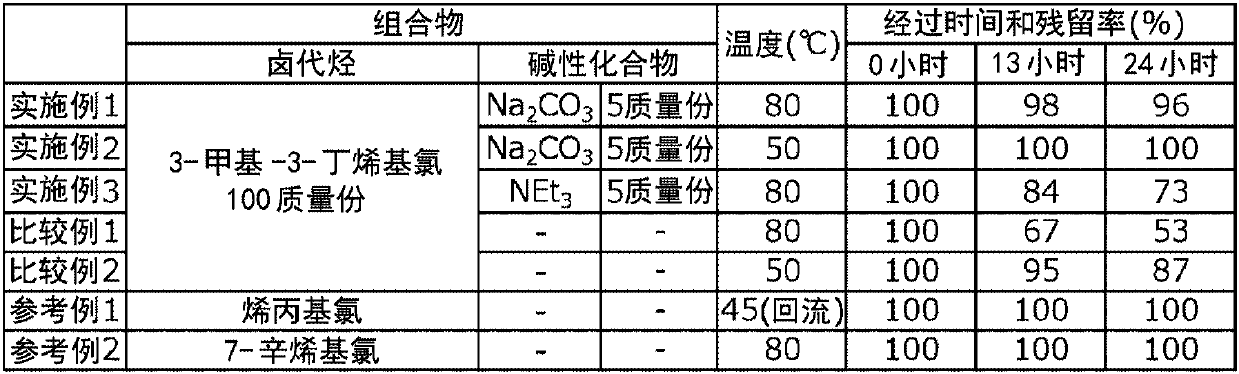

Examples

Embodiment

[0036] Hereinafter, the present invention will be specifically described based on examples, but the present invention is not limited to these examples.

Synthetic example

[0038] Add 43.06g (0.50mol) of 3-methyl-3-buten-1-alcohol, 55.65g (0.55mol) of triethylamine, ether 200 g, and the temperature of the internal mixture was cooled to 5° C. while stirring. Then, 65.43 g (0.55 mol) of thionyl chloride was added dropwise over 2.5 hours while keeping the internal temperature at 10° C. or lower. After completion of the dropwise addition, it was heated to an internal temperature of 50 to 55° C., and heated and stirred for 13 hours. After cooling, 125 g of water was added, stirred, and left to stand, then the water phase was separated, and the organic phase was washed with 130 g of a 5% aqueous sodium bicarbonate solution and 125 g of water. 235.2 g of the separated organic phase were obtained, and the organic phase was analyzed by gas chromatography, and as a result, 46.5 g (0.44 mol; yield 88%) of 3-methyl-3-butenyl chloride were contained. The reaction liquid was distilled under reduced pressure to obtain 23.3 g of 3-methyl-3-butenyl chloride (he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com