Heating element for floor or ceramic tile and preparation method

A heating element and ceramic tile technology, applied in the field of heating element and preparation, can solve problems affecting the quality of the ground, layering, uneven heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

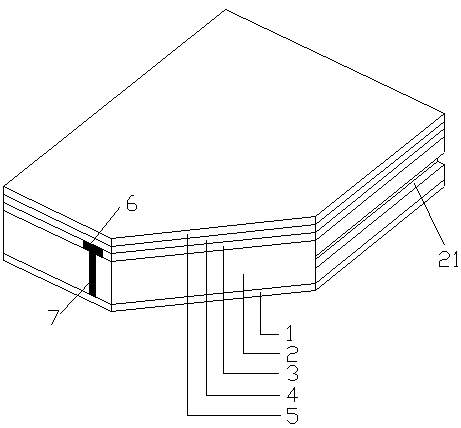

[0023] Example figure 1 As shown, the present invention is used for heating element of floor or ceramic tile to comprise balance gummed paper layer 1, oriented strand board 2, carbon fiber chip paper layer 3, wood grain paper layer 4, wear-resistant glued paper layer 5, copper electrode 7 and aluminum foil electrode 6. The balance tape layer 1, oriented strand board 2, carbon fiber chip paper layer 3, wood grain paper layer 4 and wear-resistant tape layer 5 are stacked in sequence, and the carbon fiber diameter in the carbon fiber chip paper layer 3 is 300 nm and made of short fibers and long fibers, the aluminum foil electrodes 6 are respectively arranged at both ends of the carbon fiber chip paper layer 3, and the copper electrodes 7 are arranged at both ends of the oriented strand board 2 and connected to the Aluminum foil electrode 6 is connected.

[0024] Preferably, the length of the short fibers in the carbon fiber core paper layer 3 is 25-35 nm, and the length of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com