Artificial bee colony parameter optimization-based direct torque control method for alternating-current asynchronous motor slip film variable structure

A direct torque control, asynchronous motor technology, applied in AC motor control, motor control, motor generator control, etc., can solve problems such as excessive output torque ripple, flux linkage estimation error, affecting speed regulation performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

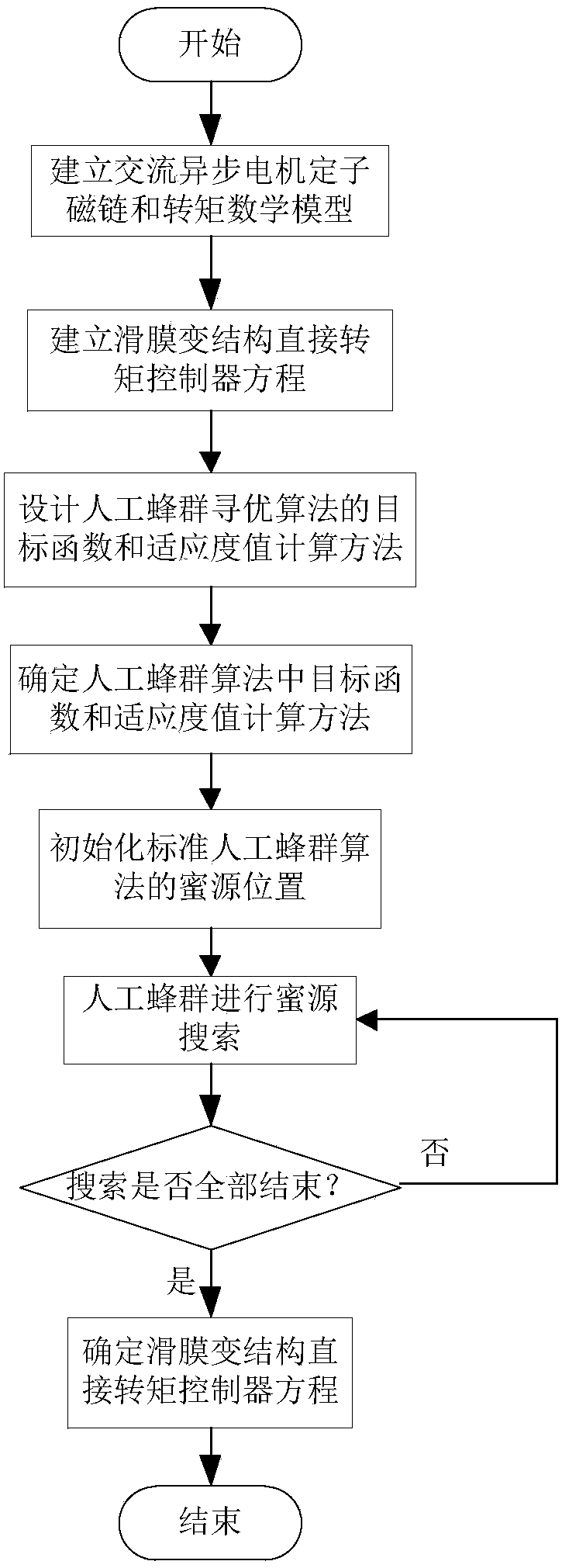

[0088] Such as figure 1 As shown, the present invention specifically adopts the following technical solutions:

[0089] A synovial film variable structure direct torque control method for an AC asynchronous motor based on artificial bee colony parameter optimization, specifically comprising:

[0090] Step 1: Establish the stator flux equation, electromagnetic torque equation and flux amplitude square expression of the AC asynchronous motor;

[0091] Step 2: Establish the direct torque controller equation of the synovial film variable structure;

[0092] Step 3: Design the objective function and fitness value calculation method of the artificial bee colony optimization algorithm;

[0093] Step 4: Initialize the honey source position of the standard artificial bee colony algorithm;

[0094] Step 5: Determine the parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com